JY-SBS Modified Bitumen Waterproofing Membrane Modified Asphalt Waterproof Membrane

JY-SBS Modified Bitumen Waterproofing Membrane is a modified asphalt waterproof membrane produced in China at Great Ocean Waterproof factory. This SBS waterproofing membrane features SBS-modified bitumen with polyester or fiberglass reinforcement, suitable for roofs, basements, tunnels, and bridges. Available in 1m x 10m rolls, 3mm or 4mm thick, with torch-on application. As the direct manufacturer, we offer it at a competitive factory price.

Product Introduction

JY-SBS Modified Bitumen Waterproofing Membrane is a rollable sheet designed for waterproofing applications. It uses polyester felt or glass fiber felt as the base layer, with styrene-butadiene-styrene (SBS) modified asphalt applied as the coating. The surface incorporates polyethylene film (PE), fine sand (S), mineral granules (M), or other isolation materials.

Compared to APP plastic modified asphalt waterproofing membranes, this sbs membrane offers improved low-temperature resistance, making it suitable for projects requiring flexibility in colder conditions. The sbs modified bitumen waterproofing membrane structure supports reliable adhesion and durability in flat or low-slope roofing systems.

In the sbs waterproofing membrane market, this product serves as a standard option for commercial and residential buildings needing long-term water barrier performance. The sbs roofing membrane format allows for torch-applied or self-adhesive installation, depending on project specifications.

| Thickness(mm) | 3.0 / 4.0 / 5.0 | Length(m) | 7.5 / 10 | Width(m) | 1.0 |

| Surface | PE / S / M | Underface | PE / S | ||

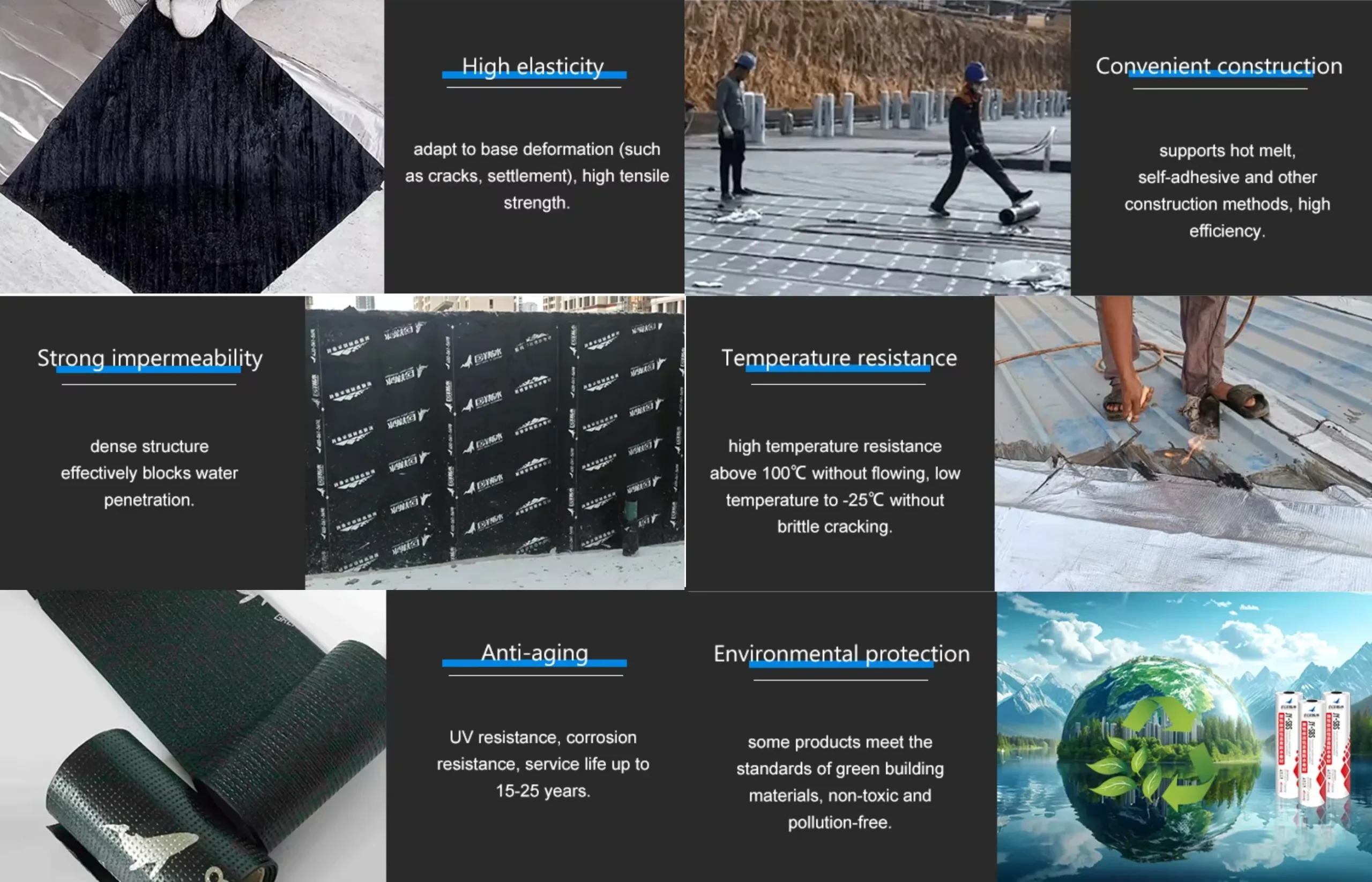

Performance Features

The JY-SBS Modified Bitumen Waterproofing Membrane delivers practical performance for demanding waterproofing jobs. It maintains flexibility with no cracks at -25°C and resists flow at 90°C, providing reliable behavior across temperature swings. The material offers solid elongation, extended service life, straightforward installation, and minimal environmental impact during application.

This sbs waterproofing membrane works well for Class I and II buildings, particularly in cold regions or structures prone to movement and deformation. Key traits include impermeability, high tensile strength, good dimensional stability, and strong resistance to base shrinkage, cracking, and deformation. It withstands puncture, abrasion, tearing, corrosion, mold, and weathering.

Compared to APP equivalents, the sbs bituminous membrane excels in low-temperature settings. Torch-applied construction allows four-season use with consistent results. As a modified bitumen waterproofing membrane, it serves as a dependable choice for flat roofs, basements, and other exposed areas. The sbs roof membrane format supports single- or multi-layer systems based on project needs.

Application Range

The modified bitumen waterproofing membrane covers a broad set of waterproofing needs across building types. On roofs, it handles flat roofs, sloped roofs, and complex configurations with protrusions, managing deformation from temperature changes. The s Sbs roof membrane (noted twice in query, used once) fits standard low-slope commercial and residential systems.

Below grade, the material serves as a foundation waterproofing membrane on basement floors and side walls to block groundwater and soil pressure. It also functions as a basement waterproofing membrane in tunnels and pipe galleries. For vertical or horizontal surfaces exposed to moisture, it acts as an exterior waterproofing membrane on bridges, roads, parking decks, swimming pools, and reservoirs.

Additional uses include interior foundation waterproofing in sanitary facilities and sbs shower waterproofing membrane applications where frequent deformation or cold climates demand flexible barriers. The membrane applies to pipelines, corrosion-protected layers, pipe wraps, and canals. It works on key waterproofing projects and civil structures like roofs, walls, bathrooms, balconies, underground rooms, and cold-region buildings.

SBS implements standard GB18242-2008

| No. | Item | Ⅰ | Ⅱ | ||||

|---|---|---|---|---|---|---|---|

| PY | G | PY | G | PYG | |||

| 1 | Soluble matter content / (g/m²) ≥ | 3mm | 2100 | * | |||

| 4mm | 2900 | * | |||||

| 5mm | 3500 | ||||||

| Experimental phenomenon | * | Tire base non combustible | * | Tire base non combustible | * | ||

| 2 | Heat resistance | °C | 90 | 105 | |||

| ≤ mm | 2 | ||||||

| Experimental phenomenon | No flow or dripping | ||||||

| 3 | Low temperature flexibility/°C | -20 | -25 | ||||

| No cracks | |||||||

| 4 | Impermeability for 30 minutes | 0.3MPa | 0.2MPa | 0.3MPa | |||

| 5 | Pulling force | Maximum peak tensile force/(N/50mm) ≥ | 500 | 350 | 800 | 500 | 900 |

| Secondary peak tension/(N/50mm) ≥ | * | * | * | * | 800 | ||

| Experimental phenomenon | There is no cracking or separation of the asphalt coating layer from the tire base in the middle of the test piece | ||||||

| 6 | Elongation rate | Maximum peak elongation/% ≥ | 30 | * | 40 | * | * |

| Elongation at the second peak/% ≥ | * | * | * | * | 15 | ||

| 7 | Oil leakage | Number of sheets ≤ 2 | |||||

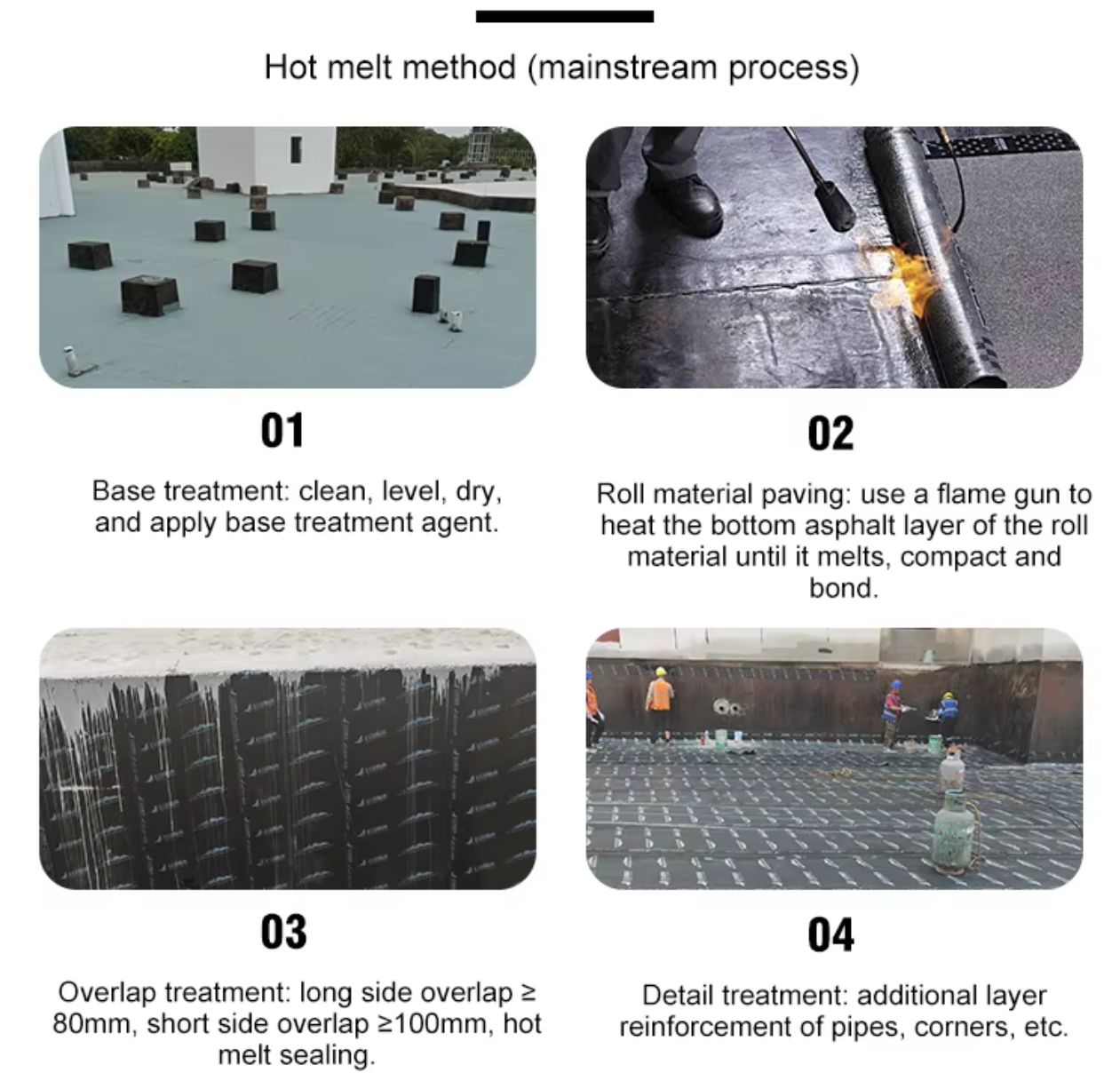

Installation Methods for JY-SBS Modified Bitumen Waterproofing Membrane

The sbs waterproofing membrane installs using standard modified bitumen techniques suited to project conditions and substrate type. Common methods include:

- Torch-Applied Installation Heat the underside of the sbs bituminous membrane with a propane torch until the asphalt softens and glistens. Roll the sheet forward onto the prepared substrate, ensuring full contact and overlap of 75–100 mm on side laps and 150 mm on end laps. Torch application works year-round and provides strong bonding on concrete, masonry, or insulation boards.

- Hot Asphalt (Mopping) Method Apply hot oxidized asphalt or SEBS-modified asphalt at 200–220°C to the substrate using a mop or mechanical spreader. Unroll the modified bitumen waterproofing membrane into the hot asphalt bed immediately while maintaining proper overlaps. This method suits large flat areas and multi-layer systems.

- Cold-Adhesive Application Use solvent-based or water-based cold adhesives spread with a squeegee or roller. Lay the membrane into the wet adhesive and press firmly with a heavy roller to eliminate air pockets. Cold application avoids open flames and suits sensitive environments or occupied buildings.

- Self-Adhesive Installation (for specific variants) Peel the release film from the pre-applied adhesive backing and roll the sbs roof membrane onto a primed surface. Apply pressure with a roller to achieve uniform adhesion. Self-adhesive sheets simplify installation on vertical surfaces, flashings, or small repair areas.

Surface Preparation (All Methods):

- Clean substrate to remove dust, debris, and loose material.

- Apply asphalt primer at 0.2–0.4 L/m² and allow to dry.

- Repair cracks wider than 3 mm with sealant or patching compound.

- Ensure substrate is dry and smooth for consistent bonding.

Safety Notes:

- Follow local fire codes during torching.

- Use PPE including gloves, boots, and eye protection.

- Maintain ventilation when using solvent-based adhesives.

Select the method based on roof design, local climate, and crew experience to achieve durable waterproofing performance.

Benefits of JY-SBS vs APP Modified Bitumen Membranes

The sbs waterproofing membrane stands out against APP (Atactic Polypropylene) versions mainly in cold-weather performance and elasticity. Key practical differences include:

- Low-Temperature Flexibility SBS stays flexible with no cracks down to -25°C, while most APP membranes stiffen and risk cracking below 0°C to -10°C. This makes the sbs bituminous membrane the go-to choice for regions with freeze-thaw cycles or structures that see movement.

- Elongation and Deformation Handling SBS offers 30–50% elongation (depending on reinforcement), compared to APP’s typical 10–20%. The extra stretch absorbs substrate shifts, thermal expansion, or settling without tearing—critical for modified bitumen waterproofing membrane systems on concrete decks or metal roofs prone to flex.

- Cold-Region Suitability Contractors install SBS year-round in sub-zero climates without special handling. APP often requires pre-warming or limits winter application, slowing projects in northern markets.

- Adhesion in Multi-Layer Systems The softer SBS compound bonds better between plies when torch-applied or mopped, reducing delamination risk over time. APP’s harder surface can need extra inter-ply asphalt to match bond strength.

- Impact and Puncture Resistance Both perform well, but SBS edges out in foot traffic or hail zones because the rubberized asphalt recovers better after indentation.

APP still holds an edge in high-heat resistance (no flow up to 120–130°C vs SBS at 90–100°C), so it suits desert roofs or industrial plants with extreme summer loads. For most standard sbs roof membrane jobs—especially where winter flexibility and movement matter—SBS delivers longer, trouble-free service.

Project Case Studies

1. Beijing North Railway Station Parking Deck

- Location: Beijing, China

- Completion: Q3 2022

- Area: 15,400 m²

- System: Double-layer torch-applied

- Base: 3 mm PY-PE (polyester + PE film)

- Cap: 4 mm PY-M (polyester + mineral granules, slate gray)

- Substrate: Precast concrete planks

- Climate: –20°C winter / 38°C summer

- Performance Note: Zero leaks reported after two winter cycles; granule retention > 95 % per ASTM D4977.

2. Chengdu Metro Line 18 Tunnel Section

- Location: Chengdu, Sichuan

- Completion: Q1 2023

- Area: 9,200 m² (side walls)

- System: Single-layer cold-adhesive

- 4 mm PY-S (polyester + fine sand)

- Substrate: Shotcrete

- Groundwater Head: 0.25 MPa

- Performance Note: Hydrostatic test passed at 0.3 MPa for 30 min; no seepage at 18-month inspection.

3. Qingdao Ocean View Residential Roof

- Location: Qingdao, Shandong

- Completion: Q4 2021

- Area: 6,800 m²

- System: Torch-applied over XPS insulation

- Base: 3 mm G-PE (glass fiber + PE film)

- Cap: 4 mm PY-M (polyester + green mineral)

- Slope: 1:100

- Performance Note: Survived Typhoon In-fa (2021) with 140 km/h gusts; no uplift or water ingress.

4. Harbin Cold-Storage Warehouse Foundation

- Location: Harbin, Heilongjiang

- Completion: Q2 2024

- Area: 4,100 m² (floor slab)

- System: Hot-mopped double layer

- Both layers: 4 mm PY-PE

- Temperature During Install: –12°C

- Performance Note: Core samples at 12 months showed inter-ply bond > 1.5 kN/m (GB/T 328.12).

FAQ – JY-SBS Modified Bitumen Waterproofing Membrane

Q1: What is the minimum temperature for torch installation? A: Substrate and ambient temperature must be ≥ 5°C. Below 0°C, use hot-air welders or pre-heat the deck with infrared heaters to avoid condensation.

Q2: Can SBS membrane be installed directly over EPS insulation? A: No. EPS melts at ~80°C. Install a cover board (≥12 mm fiber cement or perlite) or use cold-adhesive SBS over EPS.

Q3: What is the expected service life? A: 15–20 years for exposed mineral cap sheets; 25+ years in protected (buried or ballasted) systems. Life depends on UV exposure, foot traffic, and maintenance.

Q4: Is the membrane suitable for potable water tanks? A: No. Standard SBS contains bitumen solvents that may leach. Use NSF-certified PVC or EPDM liners for drinking water.

Q5: How to repair a small puncture (≤50 mm)? A:

- Clean area 150 mm beyond damage.

- Round corners of patch (SBS same type).

- Torch or cold-adhesive patch with 100 mm overlap.

- Seal edges with bitumen mastic.

Q6: What primer is required? A: Asphalt primer, coverage 0.25–0.35 L/m² on concrete; 0.15 L/m² on smooth surfaces. Dry time: 1–2 hours at 20°C.

Q7: Can it be used on zero-slope roofs? A: Yes, if positive drainage is achieved via tapered insulation (min 1:100 after settlement). Standing water >48 hours voids warranty.

Q8: Is flood testing required? A: Recommended for below-grade work. Plug drains, fill 50 mm water, hold 24 hours. Mark and repair any leaks before protection layer.

Q9: What is the difference between PY and G base? A: PY (polyester) = higher elongation, used on roofs with movement. G (glass fiber) = higher stiffness, used on stable substrates or as base sheet under heavy ballast.

Q10: Does the membrane resist root penetration? A: No. For green roofs, add a separate root-barrier layer (HDPE or copper-foil) above the SBS cap sheet.

About Our Factory – Great Ocean Waterproof Technology Co., Ltd.

Great Ocean Waterproof Technology Co., Ltd. (formerly Weifang Great Ocean New Waterproof Materials Co., Ltd.) operates from Tai Tou Town, Shouguang City—the heart of China’s largest waterproofing materials production base. Founded in 1999, the company integrates R&D, manufacturing, and sales as a state-recognized high-tech enterprise in the waterproofing sector.

The 26,000 m² facility houses multiple advanced production lines for rolled membranes, sheet materials, and liquid coatings. Key equipment meets domestic top standards and supports the full range of products, including the JY-951 Waterborne Polyurethane Waterproof Coating.

Certifications & Quality Assurance

- National Ministry of Agriculture “Total Quality Management Compliance”

- ISO 9001 Quality Management System

- China Quality Inspection Association “Nationally Certified Product”

- Shandong Province Industrial Product Registration Certificate

- Industrial Production License

A dedicated technical team, complete testing laboratory, and strict process controls ensure batch-to-batch consistency. All products, including JY-951, undergo raw-material inspection, in-line monitoring, and final release testing.

Market Reach Products serve projects in over 20 provinces across China and export to multiple overseas markets. The company upholds contract reliability and customer-first service under the motto “Integrity, Pragmatism, Innovation” and the goal of “Win-Win Partnership.”