Introduction to Waterproofing Solutions

In the realm of construction and building preservation, the prevention of water intrusion stands as a critical imperative. Waterproofing membranes serve as essential barriers, shielding structures such as roofs, foundations, and basements from moisture-related degradation, which can precipitate extensive repairs and compromise structural integrity. Within this array of protective materials, the TPO su izolyasiya membranı emerges as a highly adaptable and dependable selection for both commercial and residential endeavors. Composed of thermoplastic polyolefin, this material has ascended in prominence owing to its harmonious integration of superior performance, economic viability, and installation simplicity. This comprehensive exposition will meticulously examine the attributes that render TPO an optimal choice, encompassing its formulation, advantages, diverse implementations, and juxtapositions with alternative substances.

Understanding TPO Waterproofing Membrane

Composition and Manufacturing Process

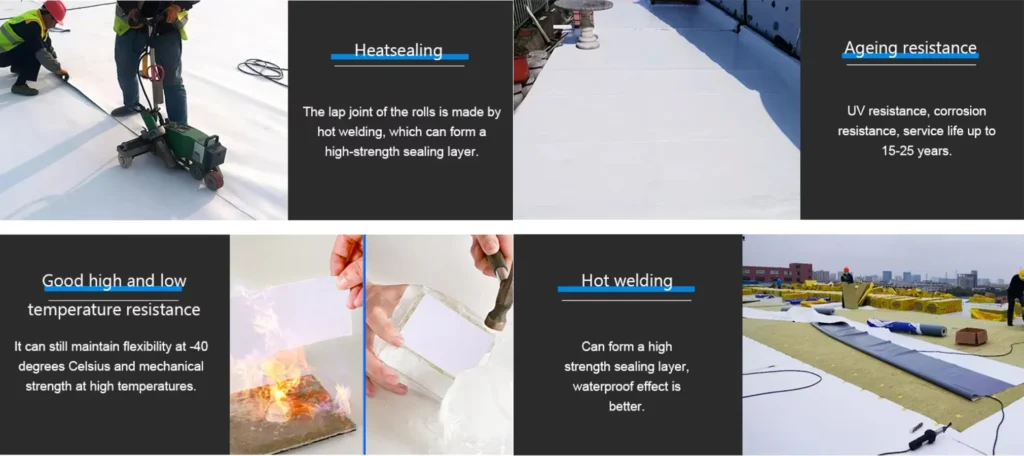

TPO, denoting Thermoplastic Polyolefin, constitutes a single-ply membrane synthesized from a amalgamation of polypropylene and ethylene-propylene rubber, fortified by reinforcements such as polyester or fiberglass to augment tensile strength. This distinctive composition facilitates heat-welding during deployment, yielding impervious seams that bolster its impermeable qualities. Manufactured within specialized tpo membrane waterproofing factories worldwide, these membranes are extruded into sheets of assorted gauges, typically spanning 45 to 80 mils, tailored to accommodate varying climatic exigencies. The production sequence entails the extrusion of the polymeric admixture into planar forms, followed by cooling and precision trimming, thereby upholding uniformity and adherence to stringent quality benchmarks.

Key Properties of TPO

Distinguishing TPO is its remarkable resilience against ultraviolet radiation, ozone degradation, and chemical assaults, rendering it apt for environments characterized by inclement weather. In contrast to conventional counterparts, TPO preserves pliability under subzero conditions without embrittlement, thereby mitigating fracture risks across temporal spans. Its pale or luminous hue deflects solar rays, fostering thermal efficiency by diminishing interior cooling requisites. Moreover, TPO’s recyclability resonates with contemporary sustainable construction ethos, minimizing ecological footprints. Additional attributes encompass puncture resistance, microbial inhibition, and compatibility with diverse substrates, ensuring versatile applicability.

Benefits of Using TPO Waterproofing Membrane

Davamlılıq və uzunömürlülük

A paramount merit of the TPO waterproofing membrane resides in its protracted service life, frequently surpassing 20 to 30 years contingent upon diligent upkeep. This endurance derives from its fortitude against perforations, lacerations, and biological proliferation, prevalent afflictions in humid milieus. In locales susceptible to copious precipitation or cryospheric accumulations, TPO’s resilient architecture guarantees sustained safeguarding devoid of recurrent substitutions, thereby curtailing long-term expenditures.

Energy Efficiency and Cost Savings

Through solar reflectance, TPO moderates edifice temperatures, engendering diminished energy outlays. This albedo characteristic may accredit structures for LEED endorsements, attracting environmentally attuned stakeholders. Temporally, the preliminary outlay in TPO amortizes via abated maintenance and utility disbursements, positioning it as a judicious fiscal alternative for expansive undertakings. Furthermore, its lightweight constitution alleviates structural burdens, potentially economizing on foundational reinforcements.

Ease of Installation and Maintenance

TPO’s emplacement is efficacious, encompassing mechanical affixation, comprehensive adhesion, or ballast methodologies. Innovations such as tpo roofing self adhesive waterproofing membrane expedite proceedings by obviating supplementary binders, accelerating adhesion whilst assuring robust cohesion. Upkeep entails sporadic evaluations to eradicate detritus and scrutinize junctures, fostering operational continuity with nominal intervention.

Environmental and Safety Advantages

TPO membranes necessitate diminished energy inputs during fabrication relative to analogous products and eschew chlorine, facilitating end-of-life reclamation. Their formulation circumvents volatile organic compounds, enhancing occupational safety during installation and mitigating atmospheric emissions.

Applications of TPO Waterproofing Membrane

Dam örtüyü sistemləri

Predominantly deployed in planar or minimally inclined roofing configurations where hydrostatic pooling poses hazards, TPO excels in commercial and industrial contexts. The self adhesive waterproofing membrane for roof iteration is especially favored for its expeditious integration in novel edifices or refurbishments, furnishing an impermeable envelope resilient to aeolian elevation and thermic oscillations.

Foundation and Basement Protection

Extending beyond overhead coverings, TPO functions efficaciously as a foundation waterproofing membrane, affixed to external facades to impede phreatic infiltration. Analogously, as a basement waterproofing membrane, it erects a bulwark against edaphic humidity ascension, preserving subterranean environs from mycotic proliferation and architectural erosion. In metropolitan expansions with spatial constraints, this utility safeguards habitable hypogean levels sans jeopardizing security.

Other Specialized Uses

TPO’s adaptability permeates verdant roofing assemblages or esplanade platforms, sustaining flora whilst upholding hermeticity. Its utility encompasses aquatic reservoirs, subterranean conduits, and impoundments, where containment fidelity is indispensable. In infrastructural ventures, TPO fortifies bridges and viaducts against aqueous corrosion, prolonging infrastructural longevity.

Comparing TPO to Other Waterproofing Materials

Traditional Bitumen-Based Options

Vis-à-vis sbs hidroizolyasiya membranı, predicated upon styrene-butadiene-styrene augmented bitumen, TPO proffers enhanced thermal endurance and reduced mass, alleviating architectural encumbrances. Whereas SBS manifests robustness, its torch-applied modality incurs conflagration perils, which TPO circumvents via thermal fusion. Similarly, membran su yalıtımı tətbiqi, leveraging atactic polypropylene, affords commendable adherence yet may falter in emulating TPO’s radiative deflection.

Synthetic Alternatives

PVC sheet membrane for waterproofing mirrors TPO in malleability but incorporates plasticizers prone to migration, conceivably abbreviating durability. TPO, devoid of such adjuncts, sustains efficacy sans ecological apprehensions. Self adhered waterproofing membrane variants in PVC exist, albeit TPO’s photostability frequently renders it preferential for overt exposures.

High-Density and Coating Solutions

Hdpe waterproofing membrane, fabricated from high-density polyethylene, predominates in subterrestrial deployments owing to its chemoresistance, yet it deficient in TPO’s seam amalgamation facility. For fluidic applications, poliuretan suya davamlı örtük delivers seamless overlay on anomalous contours, necessitating plural strata and solidification intervals, divergent from TPO’s laminar deployment alacrity.

Installation Considerations and Best Practices

Optimal TPO integration mandates meticulous substrate preparation, ensuring planar, desiccated, and contaminant-free surfaces. Professional applicators should adhere to manufacturer directives, incorporating ancillary elements like insulation and vapor retardants for holistic system efficacy. Climatic deliberations, such as evading installation amid precipitation or extreme thermal variances, are pivotal to seam integrity.

Maintenance and Long-Term Performance

Routine surveillance encompasses seam scrutiny, detritus expurgation, and puncture rectification. Prompt remediation of impairments forestalls escalation, perpetuating warranty validity. In adversarial climes, augmented inspections post-tempestuous episodes safeguard enduring functionality.

Choosing the Right TPO Waterproofing Membrane

Electing a TPO variant necessitates appraisal of meteorological patterns, edifice typology, and fiscal parameters. Collaboration with specialists ensures regulatory conformity and guaranty procurement. For bespoke superior alternatives, peruse our repository at http://great-ocean-waterproof.com/, wherein Great Ocean Waterproof proffers an assortment of premium membranes underpinned by extensive sectoral acumen.

Conclusion: The Future of Waterproofing with TPO

The TPO waterproofing membrane epitomizes an avant-garde paradigm in structural fortification. Its synthesis of resilience, proficiency, and malleability designates it as a preeminent option for architects, constructors, and proprietors. By electing TPO, one not merely insulates an edifice but assures its perdurability and ecological viability across epochs. Should your initiative necessitate such safeguards, delving into TPO may constitute the linchpin to efficacious, economical outcomes.