TPO Thermoplastic Polyolefin Waterproofing Membrane

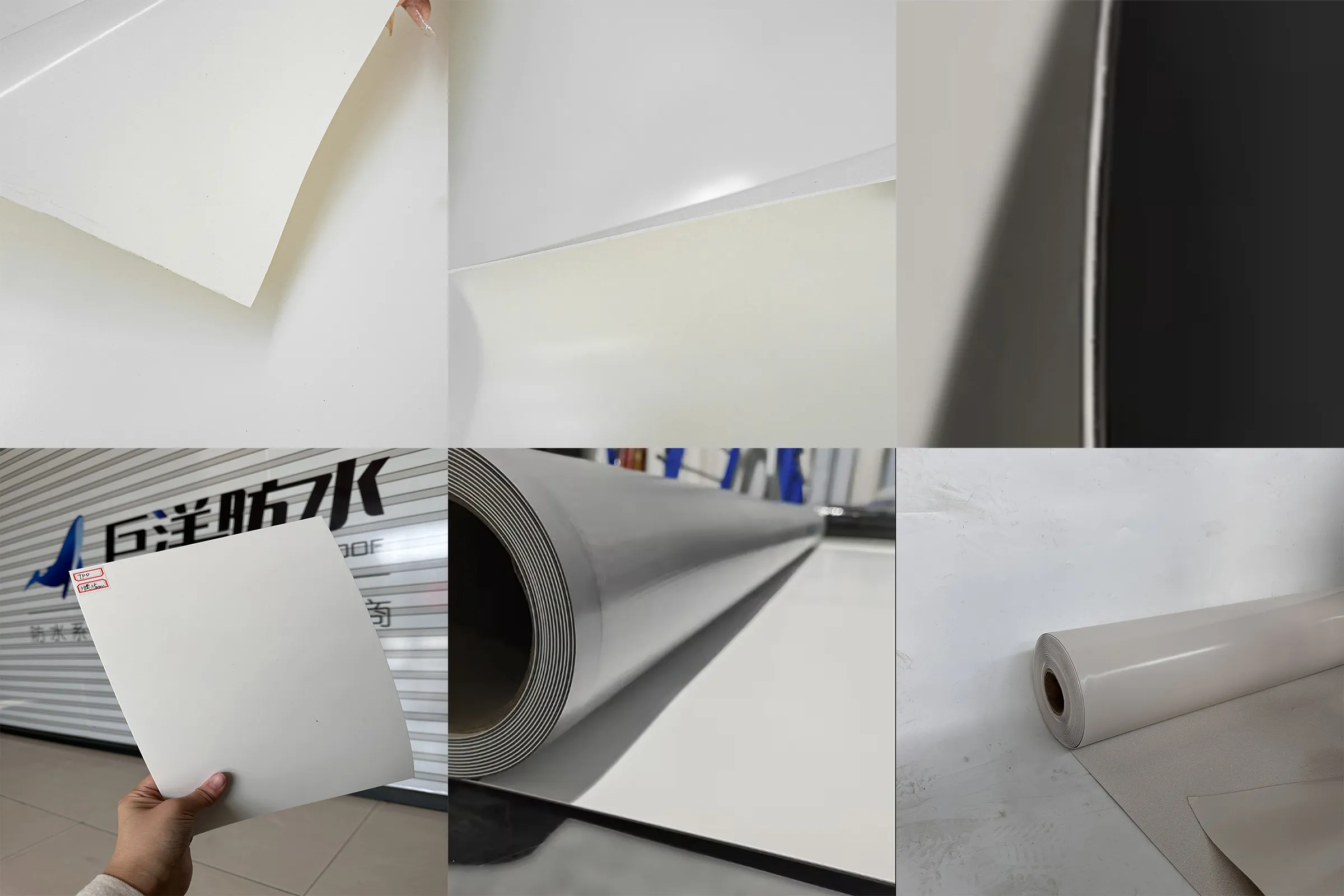

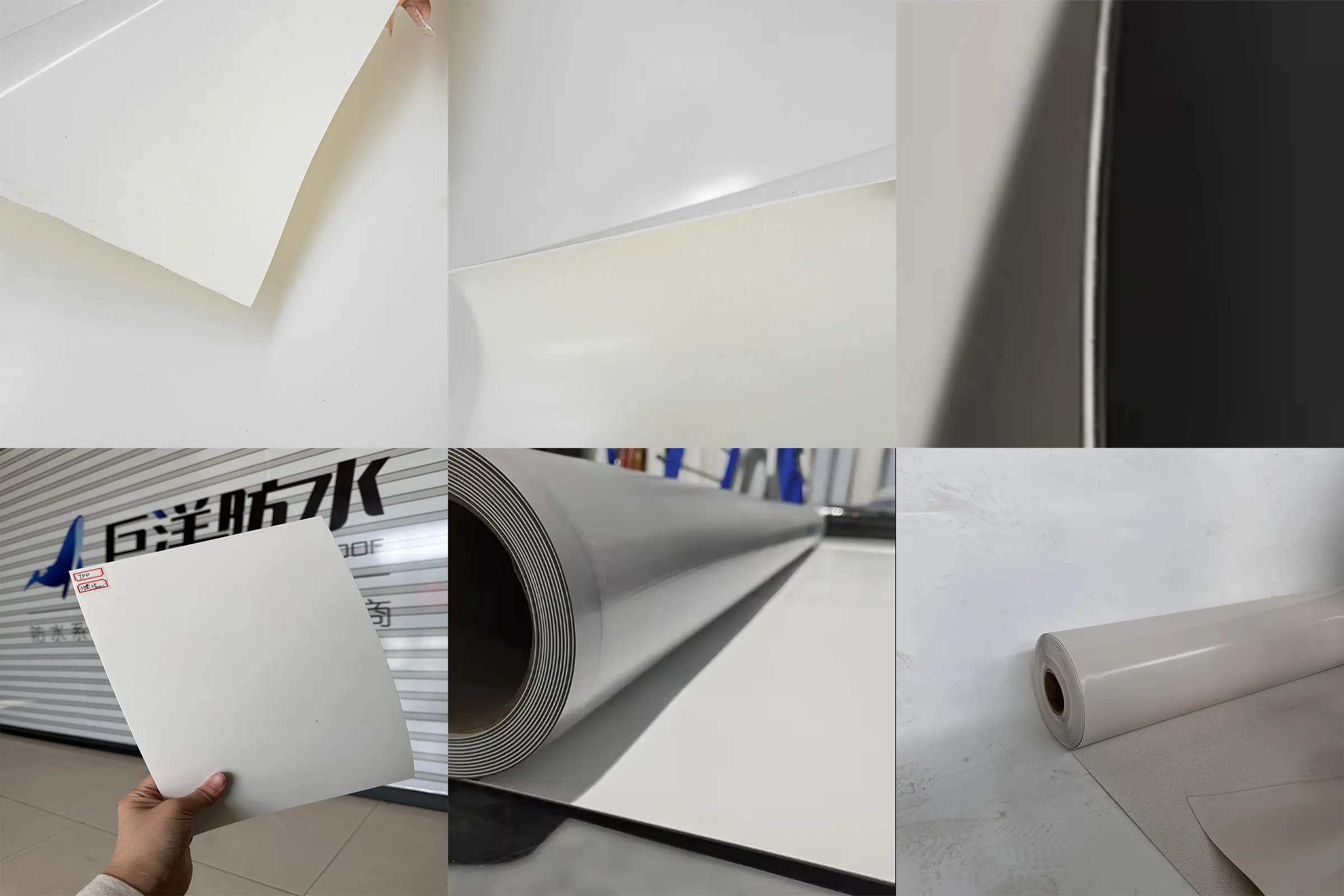

Ang Great Ocean Waterproof espesyalista sa TPO Thermoplastic Polyolefin Waterproofing Membrane, nga gihimo sa among pabrika sa Shandong Province, China. Isip usa ka dedikado nga tiggama, nagpunting kami sa paghimo og kasaligan nga mga materyales sa waterproofing sa tpo membrane nga nakakab-ot sa mga sumbanan sa industriya alang sa kalig-on ug performance. Ang among tpo waterproof membrane adunay single-ply nga konstruksyon nga adunay reinforced layers, nga nagtanyag og resistensya sa UV exposure, kemikal, ug mga puncture, nga naghimo niini nga angay alang sa komersyal nga atop, pond liners, ug mga proyekto sa waterproofing sa ilawom sa yuta. Gipasiugda namo ang praktikal nga mga istruktura sa presyo base sa gidaghanon ug mga detalye, nga nagsiguro sa pagka-accessible alang sa lainlaing mga panginahanglanon sa konstruksyon nga wala’y kinahanglan nga pagkakomplikado. Kini nga produkto anaa sa standard nga gilapdon ug gibag-on, nga adunay mga kapilian alang sa heat-weldable seams aron mapadali ang episyente nga pag-instalar. Alang sa dugang nga mga detalye sa mga aplikasyon o pag-customize, kontaka kami direkta.

Pasiuna sa Produkto

TPO Ang waterproofing membrane usa ka single-ply roofing ug waterproofing sheet nga hinimo gikan sa thermoplastic polyolefin, nga nagsagol sa ethylene propylene (EP) rubber ug polypropylene pinaagi sa advanced polymerization. Gipaila sa merkado sa US niadtong 1980s ug gipino sa sayong bahin sa 1990s, kini gidisenyo alang sa patag o ubos nga slope nga mga aplikasyon sa atop diin ang mechanical fastening naghatag og luwas nga pag-instalar nga walay dugang nga plasticizers o chlorine.

Ang materyal nagtanyag og lig-on nga performance sa bisan unsang temperatura, dili daling matigulang, nagmintinar sa pisikal nga mga kabtangan, ug nagsuporta sa prangka nga pagwelding para sa integridad sa tinahian. Kon itandi sa tradisyonal nga mga kapilian, ang tpo waterproof membrane naghatag og ubos nga thermal flexibility, kalig-on batok sa stress sa palibot, ug pagkaangay sa lain-laing mga substrate. Sa ibabaw nga nawong, ang usa ka light-colored reflective layer nagpamenos sa pagsuhop sa kainit, nga makatabang sa energy efficiency nga walay mga kabalaka sa kaluwasan sa kalikopan o konstruksyon.

Ang Great Ocean Waterproof naghimo niining rollable tpo waterproof membrane nga mga tiggama gamit ang gipauswag nga fiber-reinforced formulations ug tukmang extrusion processes aron masiguro ang makanunayong gibag-on, kusog sa weld, ug dugay nga resistensya sa tubig para sa mga komersyal ug industriyal nga proyekto.

| Gibag-on (mm) | 1.2 / 1.5 / 1.8 / 2.0 | Gitas-on (m) | 25 | Lapad (m) | 1.0 / 2.0 |

Pangunang mga Kinaiya

- Mga tinahian nga gi-welding sa init nga hangin – Ang mga lap joint gi-fuse gamit ang init nga hangin, nga nagahatag ug taas nga kalig-on sa pagpanit ug usa ka padayon, selyado nga tpo waterproofing membrane layer.

- Dugang nga resistensya sa pagkatigulang – Gipormula nga walay plasticizer para sa dugay nga panahon ug kalig-on sa UV.

- Pagka-flexible sa bugnaw nga panahon – Mopadayon sa pagkahumok hangtod sa -40 °C, nga angay alang sa pag-instalar ug paggamit sa lisod nga klima sa tingtugnaw.

- Kemikal ug biyolohikal nga resistensya – Makasugakod sa pagkaladlad sa mga asido, alkali, asin, ug pagtubo sa mikrobyo.

- Pagsukol sa pagtusok – Ang dasok nga polymer matrix ug lig-on nga kalig-on sa seam naghatag og kasaligang pisikal nga babag.

- Ibabaw nga makadaginot sa enerhiya – Ang luspad nga kolor sa pagkahuman mobanaag sa kadaghanan sa radyasyon sa adlaw, nga mopaubos sa temperatura sa ibabaw sa atop ug mopabugnaw sa mga karga.

- Mga kapilian sa kolor – Anaa sa daghang mga kolor nga labaw sa standard nga mga kolor sa suga aron mahiusa sa estetika sa bilding.

Ang Great Ocean Waterproof naggama og tpo membrane waterproofing rolls sa standard nga 1.2 mm, 1.5 mm, ug 2.0 mm nga gibag-on para sa mga flat-roof system.

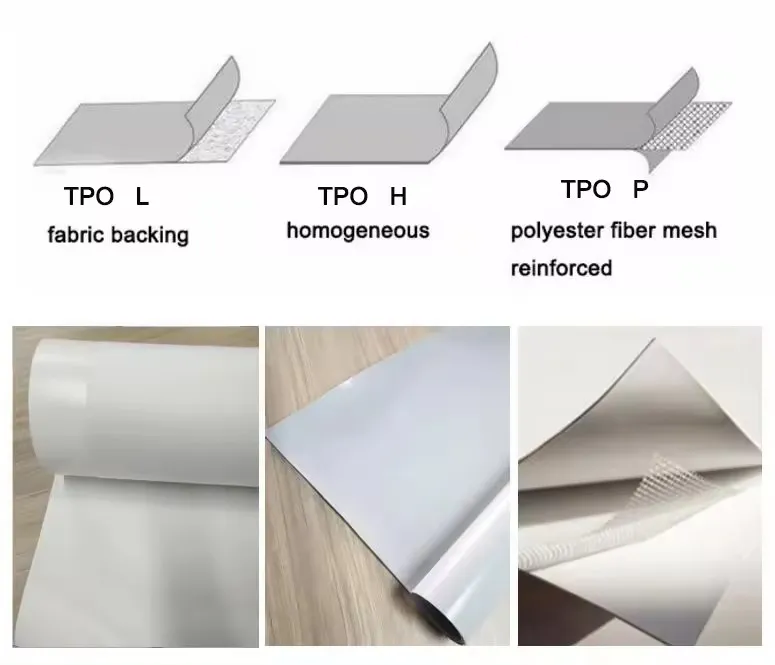

Tulo ka Matang sa Great Ocean TPO Waterproofing Membrane

| Type | Kodigo | Istruktura | Pangunang Aplikasyon |

|---|---|---|---|

| Gipaluyohan sa Tela | TPO L | Ang TPO sheet nga gi-laminate ngadto sa non-woven polyester fleece sa ilawom | Bug-os nga mipilit nga mga sistema ibabaw sa konkreto, kahoy, o dili regular nga mga deck; maayo kaayo nga kalig-on sa pagdikit gamit ang PU foam o low-VOC adhesives. |

| Homogenous | TPO H | Usa ka layer nga wala gipalig-on nga TPO sheet | Mga atop nga may ballast, mga sistema sa gaan nga gihigot gamit ang mekanikal nga paagi, o mga protektadong membrane assemblies (mga atop nga baliktad). |

| Gipalig-on sa Polyester | TPO P | Mga lut-od sa ibabaw/ubos nga TPO nga adunay gisulod nga polyester scrim mesh | Mga sona nga kusog ang hangin nga gihigot gamit ang mekanikal nga paagi; labing taas nga resistensya sa paggisi ug pagbira sa fastener. |

Gamit ang estandard nga GB27789-2011

| Dili. | butang | Indikasyon | |||

|---|---|---|---|---|---|

| H | L | P | |||

| 1 | Gibag-on sa resin layer sa tunga nga base sa ligid/mm ≥ | - | - | 0.4 | |

| 2 | Pagpasundayag sa tensyon | Pinakataas nga kusog sa tensile/(N/cm) ≥ | - | 200 | 250 |

| kusog sa tensile/MPa ≥ | 12.0 | - | - | ||

| Elongasyon sa pinakataas nga tensyon/% ≥ | - | - | 15 | ||

| elongation at break/% ≥ | 500 | 250 | - | ||

| 3 | Rate sa pagbag-o sa gidak-on sa pagtambal sa kainit / % ≤ | 2.0 | 1.0 | 0.5 | |

| 4 | Ubos nga temperatura nga pagliko nga kabtangan | -40°C Walay mga liki | |||

| 5 | Dili masudlan sa tubig | 0.3MPa, 2h, dili masudlan sa tubig | |||

| 6 | resistensya sa epekto | 0.5kg·m, dili masudlan og tubig | |||

| 7 | Pagsukol sa mga static nga kargausa ka | - | - | 20kg, dili masudlan og tubig | |

| 8 | Kusog sa pagpanit sa lutahan/(N/mm) ≥ | 4.0 | - | 3.0 | |

| 9 | Kusog sa pagkagisi sa tuo nga anggulo/(N/mm) ≥ | 60 | - | - | |

| 10 | kusog sa pagkagisi sa trapezoid/(N) ≥ | - | 250 | 450 | |

| 11 | Rate sa pagsuhop sa tubig/(70°C 168h)/% ≤ | 4.0 | 4.0 | 4.0 | |

| 12 | pagtigulang sa kainit (115°C) | Oras/oras | 672 | ||

| panagway | Walay mga bula, liki, delamination, bonding, o mga buslot | ||||

| Pinakataas nga tensile retention rate/% ≥ | - | 90 | 90 | ||

| Rate sa pagpabilin sa kusog sa tensile/% ≥ | 90 | - | - | ||

| Rate sa pagpabilin sa elongation sa pinakataas nga tensyon/% ≥ | - | - | 90 | ||

| Rate sa pagpabilin sa elongation sa break/% ≥ | 90 | 90 | - | ||

| Ubos nga temperatura nga pagliko nga kabtangan | -40°C, Walay mga liki | ||||

| 13 | resistensya sa kemikal | panagway | Walay mga bula, liki, delamination, bonding, o mga buslot | ||

| Pinakataas nga tensile retention rate/% ≥ | - | 90 | 90 | ||

| Rate sa pagpabilin sa kusog sa tensile/% ≥ | 90 | - | - | ||

| Rate sa pagpabilin sa elongation sa pinakataas nga tensyon/% ≥ | - | - | 90 | ||

| Rate sa pagpabilin sa elongation sa break/% ≥ | 90 | 90 | - | ||

| Ubos nga temperatura nga pagliko nga kabtangan | -40°C Walay mga liki | ||||

| 14 | Ang artipisyal nga klima nagpadali sa pagkatigulang | Oras/oras | 1500usa ka | ||

| panagway | Walay mga bula, liki, delamination, bonding, o mga buslot | ||||

| Pinakataas nga tensile retention rate/% ≥ | - | 90 | 90 | ||

| Rate sa pagpabilin sa kusog sa tensile/% ≥ | 90 | - | - | ||

| Rate sa pagpabilin sa elongation sa pinakataas nga tensyon/% ≥ | - | - | 90 | ||

| Rate sa pagpabilin sa elongation sa break/% ≥ | 90 | 90 | - | ||

| Ubos nga temperatura nga pagliko nga kabtangan | -40°C Walay mga liki | ||||

Mga Aplikasyon

- Mga atop nga patag ug ubos ang bakilid – Pangunang gamit sa mga bodega sa industriya, mga sentro sa komersyo, mga bilding sa opisina, mga ospital, mga eskwelahan, ug uban pang mga pasilidad publiko nga nanginahanglan og lig-on nga single-ply membrane sa waterproofing nga tpo mga sistema.

- Mga sistema nga gihigot sa mekanikal – Ang gipauswag (gipalig-on) nga mga rolyo i-install gamit ang mga tornilyo ug mga plato sa nagsapaw nga seam, sulundon alang sa mga steel deck o gaan nga konkreto diin ang resistensya sa pag-alsa sa hangin hinungdanon.

- Mga sistema nga hingpit nga gisunod – Ang mga fleece-backed roll direktang motapot sa substrate gamit ang low-VOC contact adhesives o polyurethane foam, nga angay para sa dili regular nga mga deck, kahoy, o pag-retrofit sa ibabaw sa kasamtangang mga membrane.

- Mga sistema nga adunay ballast – Ang standard homogenous rolls mosuporta sa bato o mga pavers nga gihugasan sa suba isip ballast, nga kasagarang gipiho para sa dako nga lugar nga tpo mga atop nga dili masudlan og tubig nga membrane nga adunay gamay nga mga penetrasyon.

- Mga asembliya sa berde ug asul nga atop – Ang mga compatible nga root-barrier layers nagtugot sa TPO nga magsilbing base waterproofing ubos sa halapad o intensive vegetation systems.

Ang Great Ocean nagsuplay sa tanang tulo ka klase sa rolyo (homogeneous, reinforced, fleece-backed) nga may gibag-on nga 1.2–2.0 mm aron mohaom sa disenyo sa proyekto ug mga kinahanglanon sa lokal nga code.

TPO vs. EPDM Waterproofing Membranes

| Aspeto | TPO Waterproofing Membrane | EPDM Waterproof Membrane |

|---|---|---|

| Materyal nga Basehan | Thermoplastic polyolefin – sinagol nga polypropylene ug ethylene-propylene rubber nga adunay polyester scrim reinforcement. | Ethylene propylene diene monomer – thermoset nga sintetikong goma, kasagaran gipalig-on gamit ang polyester o fiberglass. |

| Pamaagi sa Pagtahi | Ang mga hot-air welded seams makamugna og monolithic, thermoplastic bond nga maghiusa sa mga sheets. | Mga adhesive tape o liquid adhesive; ang mga tinahian nagpabilin nga mekanikal nga mga lutahan, dili molekular. |

| Kolor ug Pagpabanaag sa Init | Ang standard nga puti nga nawong mo-reflect og 75–85% nga solar radiation (Cool Roof rated); mopakunhod sa urban heat island effect. | Itom nga estandard; adunay mga bersyon nga giputos og puti apan adunay dugang nga lut-od nga gipadapat sa uma nga daling madaot. |

| Temperatura sa Pag-instalar | Mahimong i-install sa mas bugnaw nga panahon (hangtod sa 20°F/-7°C) tungod kay ang kagamitan sa welding makamugna og kaugalingong kainit. | Nagkinahanglan og temperatura nga labaw sa 40°F/4°C para sa kadaghanan sa mga adhesive; adunay mga tape nga magamit sa bugnaw nga panahon apan mas hinay. |

| Pagka-flexible sa Ubos nga Temperatura | Mogahi ubos sa 0°F/-18°C; mahimong magkinahanglan og dugang pag-amping sa grabeng katugnaw sa klima. | Magpabiling flexible hangtod sa -50°F/-45°C; sulundon alang sa mga rehiyon nga nag-freeze-thaw. |

| Pagsukol sa Kemikal | Maayong resistensya sa mga lana, grasa, ug kadaghanan sa mga kemikal sa atop; compatible sa mga tambutso sa restawran. | Maayo kaayong resistensya sa mga asido, polar solvents, ug mga tambok sa hayop; kaylap nga gigamit sa mga planta sa pagproseso sa pagkaon. |

| Pagtigulang sa UV ug Ozone | 5,000–8,000 ka oras nga gipaspasan nga pagsulay sa UV; dugay nga kalig-on sa kolor sa puti nga mga bersyon. | 10,000+ ka oras; ang itom nga nawong mosuhop sa UV apan dili madaot sa mekanikal nga paagi. |

| Gidak-on ug Timbang sa Rolyo | 10 ft × 100 ft (1,000 sq ft) nga komon; 45–60 mil nga gibag-on nga may gibug-aton nga ~0.3 lb/sq ft. | 10–50 ft ang gilapdon, hangtod sa 200 ft ang gitas-on; 45–60 mil ang gibug-aton nga ~0.3 lb/sq ft. |

| Pag-ayo | Patch nga adunay parehas nga TPO ug hot-air weld; walay putol nga integrasyon. | Patch nga adunay wala ma-cure nga EPDM ug primer/tape; ang tinahian magpabilin nga makita ug mekanikal. |

| Pagkamagamit pag-usab | Thermoplastic – mahimong galingon pag-usab ug gamiton pag-usab sa mga produkto nga ubos og kalidad. | Thermoset – dili ma-recycle; ipadala sa landfill sa katapusan sa kinabuhi. |

| Kasagaran nga Garantiya | 20–30 ka tuig (materyales + trabaho) gikan sa mga tiggama sa tpo waterproofing membrane kon i-install sumala sa espesipikasyon. | 20–30 ka tuig nga materyal; lainlain ang sakop sa trabaho. |

| Gasto (Materyal Lamang) | $0.70–$1.10 kada sq ft (45–60 mil nga puti). | $0.60–$0.90 kada sq ft (45–60 mil nga itom). |

Dali nga Pagdala

- Pagpili TPO para sa mga episyente sa enerhiya, puti nga atop sa init o kasarangan nga klima diin importante ang gikusgon sa hot-air welding ug ang pagka-recycle niini.

- Pagpili EPDM para sa ngitngit nga mga atop, grabeng katugnaw, o mga proyekto nga adunay grabeng pagkaladlad sa kemikal diin ang napamatud-an nga 40+ ka tuig nga track record mas labaw pa sa kalig-on sa tahi.

Ang Great Ocean Waterproof nagsuplay sa duha ka sistema ug nagpares sa klase sa membrane sa mga kondisyon sa proyekto.

Mga Review sa Kustomer

John M. – Kontratista sa Atop, Chicago, USA “Nag-instalar og 28,000 sq ft sa usa ka bodega nga giayo sa miaging tingtugnaw. Ang hot-air welder nagtrabaho nga walay problema sa 15 °F (-9 °C) ug ang mga tinahian nasulayan nga 100 % dili masudlan og tubig gamit ang vacuum box. Ang puti nga nawong miubos sa temperatura sa atop og 22 °F kon itandi sa daan nga itom nga EPDM. Ang kliyente nakakita og 18 ka % nga mas ubos nga bayranan sa AC karong ting-init.”

Maria S. – Tagdumala sa Pasilidad, São Paulo, Brazil “Gipili namo ang 1.5 mm gray nga TPO para sa pagpalapad sa usa ka shopping mall. Ang kolor niini mitakdo sa kasamtangang façade ug ang gibug-aton sa roll (0.29 lb/sq ft) nagtugot sa mga tripulante nga makatabon og 1,200 m² kada adlaw uban sa upat ka tawo nga team. Walay mga leak human sa duha ka ting-ulan ug ang lokal nga inspektor sa panglawas mipasar sa atop para sa duol nga tambutso sa food court.”

Ahmed R. – Inhenyero sa Proyekto, Dubai, UAE “Gitakda nga 60-mil TPO para sa 45,000 m² nga logistics center. Ang light reflectance nagpabilin sa nawong nga ubos sa 70 °C sulod sa 48 °C nga mga adlaw—kritikal para sa among solar-panel array sa ibabaw. Walay napakyas nga seam sulod sa 24 ka bulan bisan pa sa kusog nga hangin nga miabot sa 110 km/h. Ang teknikal nga representante sa Great Ocean miabot alang sa unang weld test; propesyonal kaayo.”

Lars K. – Tag-iya sa Bilding, Oslo, Norway “Gipulihan ang 30-anyos nga felt sa gym sa eskwelahan. Ang -40 °C nga flexibility rating naghatag kanamo og pagsalig alang sa tingtugnaw sa Nordic. Gi-install niadtong Nobyembre nga walay mga heater. Nagdula na usab og basketball ang mga bata ug ang atop morag bag-o gihapon human sa duha ka siklo sa niyebe. Sayon ra ang mga papeles sa warranty.”

Sophie L. – Arkitekto, Vancouver, Canada “Gigamit namo ang 1.2 mm TPO sa usa ka mixed-use mid-rise. Ang lain-laing mga kolor nagtugot kanamo sa pagtagbaw sa urban-design panel sa siyudad samtang gipadayon ang SRI nga labaw sa 78. Ang mekanikal nga pagkabit sa sistema dali nga naguba sa ibabaw sa konkreto nga deck. Walay callbacks sulod sa 18 ka bulan ug ganahan ang tag-iya sa mas ubos nga mga invoice sa enerhiya.”

Rajesh P. – Distributor, Mumbai, India “Naka-stock og 40 ka rolyo nga 2.0 mm para sa mga proyekto sa baybayon nga daling maagian og monsoon. Ang mga kustomer wala magreport nga ang tubig mosulod bisan sa mga terrace nga daghang tawo ang maglakaw. Ang resistensya niini sa pagkabuslot mas makasugakod sa mga debris sa konstruksyon kaysa sa PVC nga among gidala kaniadto. Ang pag-order pag-usab karon matag 3 ka semana.”

FAQ

P: Unsa ang kalainan tali sa 45-mil, 60-mil, ug 80-mil nga TPO? A: Ang gibag-on mao ang mopausbaw sa gidugayon sa warranty ug sa resistensya sa pagkabuslot. Ang 45-mil mao ang standard para sa mga atop nga dili kaayo daghan og tawo nga adunay 20 ka tuig nga warranty. Ang 60-mil mao ang labing komon para sa mga komersyal nga proyekto nga adunay 25-30 ka tuig nga coverage. Ang 80-mil gitino para sa mga high-traffic, kusog nga hangin, o heavy-ballast system.

P: Mahimo ba nga i-install ang TPO direkta ibabaw sa daan nga atop? A: Oo, sa usa ka recover application. Kuhaa ang luag nga graba, ayoha ang mga blister, ug butangi og cover board o separation layer. Mas maayo ang hingpit nga nagdikit nga fleece-back TPO para sa dili patas nga substrates.

P: Modalag ba ang puti nga nawong sa paglabay sa panahon? A: Dili. Ang among TPO adunay mga UV stabilizer ug walay plasticizer. Ang SRI nagpabilin nga labaw sa 78 human sa 3 ka tuig nga xenon-arc aging sumala sa ASTM G155.

P: Unsa ang pinakabugnaw nga temperatura para sa mga welding seams? A: Ang mga hot-air welder mo-operate hangtod sa 20 °F (-7 °C). Kon ubos niana, ipainit daan ang overlap gamit ang heat gun ngadto sa 50 °F (10 °C) sulod sa 30 segundos sa dili pa mag-welding.

P: Compatible ba ang TPO sa tambutso sa grasa sa atop? A: Oo. Ang polymer dili mosukol sa mga tambok ug lana sa hayop. Pagbutang og grease-guard walkway pad palibot sa mga bentilasyon sa kusina para sa mga tawo nga moagi.

P: Unsaon nako paglimpyo sa membrane kon kini mahugawan? A: Tubig nga ubos ang presyur (ubos sa 1,000 psi) ug malumo nga detergent. Likayi ang mga petroleum solvent, citrus cleaner, o abrasive pads.

P: Unsa nga mga wind-uplift rating ang makab-ot sa Great Ocean TPO? A: FM 1-90 ngadto sa 1-180 depende sa fastener pattern, klase sa deck, ug perimeter enhancement. Isumite ang mga drowing sa deck para sa custom layout.

P: Dili ba makasugakod sa gamot ang membrane para sa mga green roof? A: Ang standard nga TPO dili makasugakod sa gamot. Ipares kini og usa ka gipahinungod nga root-barrier layer (HDPE o copper-foil) ilalom sa drainage board.

P: Unsa ang lead time para sa mga kolor nga dili puti? A: Ang puti ug light gray ipadala sulod sa 5–7 ka adlaw. Ang tan, custom gray, o espesyal nga mga kolor nagkinahanglan og 3–4 ka semana nga minimum nga order nga 20 ka rolyo.

P: Ang Great Ocean ba naghatag og warranty sa trabaho ug materyales? A: Oo, hangtod sa 30 ka tuig kon i-instalar sa usa ka sertipikado nga kontraktor ug susihon. Anaa usab ang mga garantiya nga materyal lamang.

Mahitungod sa Great Ocean Waterproof Technology Co., Ltd.

Ang Great Ocean Waterproof Technology Co., Ltd. (kanhi Weifang Great Ocean New Waterproof Materials Co., Ltd.) nahimutang sa Tai Tou Town, Shouguang City—ang nanguna nga sentro sa China alang sa mga materyales sa waterproofing. Natukod niadtong 1999, ang among 26,000 m² nga integrated manufacturing campus adunay mga abante nga linya sa produksiyon alang sa mga sistema sa TPO waterproofing membrane ug usa ka kompleto nga portfolio sa mga komplementaryong solusyon sa waterproofing.

Mga Pangunang Linya sa Produkto

- TPO Waterproofing Membrane – Gi-extrude nga 1.2–2.0 mm nga homogenous, reinforced, ug fleece-backed nga mga rolyo nga adunay hot-air weldable nga mga tinahian ug taas nga UV stability.

- PVC Waterproof Membrane – Mga palid nga gipalig-on sa sulod para sa mga tunel, silong, ug sudlanan sa mainom nga tubig.

- Polyethylene-Polypropylene (PE/PP) nga Polimer nga Komposit nga Lamad – Mga rolyo nga may fiber-backed para sa mga aplikasyon nga ubos sa grado ug berde ang atop.

- CPE Waterproof Membrane – Mga high-speed-rail nga sertipikado nga chlorinated polyethylene sheet para sa imprastraktura.

- Mga SBS/APP nga Gibag-o nga mga Membrana sa Bitumen – Mga takip nga gibutangan og sulo o self-adhesive nga adunay grado nga dili madaot sa gamot.

- Mga Pre-Applied Membrane nga HDPE nga Nagdikit sa Kaugalingon – Mga rolyo nga pang-react-bonding para sa waterproofing nga dili masudlan sa tubig sa blind-side.

- HDPE Reaction-Stick Film nga Gi-Cross-Laminated – Taas nga kusog, bertikal/pahalang nga babag human sa pagbutang.

- Waterproof Coatings – Usa- ug duha-ka-komponente nga polyurethane, JS polymer-cement, spray-applied rubber asphalt, non-curing creep compound, ug 951 water-based polyurethane systems.

- Espesyal nga mga Teyp ug mga Aksesorya – Butyl nga goma, aspalto, ug mga high-elastic nga flashing nga gibutangan og likido.

Paggama ug Pagkontrol sa Kalidad

- 20+ ka awtomatikong linya nga adunay in-line thickness scanners, polymer compounding, ug lamination units.

- Kompleto nga laboratoryo nga adunay kagamitan sa pagsulay sa ASTM/GB: tensile, peel, hydrostatic, low-temp flexibility, ug accelerated weathering.

- Sertipikado ang ISO 9001; ang mga produkto adunay Lisensya sa Produkto sa Industriya sa China ug mga pag-apruba sa kalidad gikan sa nasudnong awtoridad.

Pag-abot sa Merkado

Ang lokal nga halin naglangkob sa kapin sa 20 ka probinsya; ang gidaghanon sa eksport nagserbisyo sa North America, Middle East, Southeast Asia, ug Europe. Ang on-site technical support naglakip sa weld training, mock-ups, ug system design para sa TPO waterproof membrane ug hybrid installations.

Ang Great Ocean naglihok ubos sa pilosopiya nga "win-win"—nga naghatud sa kasaligan, mga materyales nga nagsunod sa code sa kompetisyon nga presyo nga adunay responsive nga serbisyo.