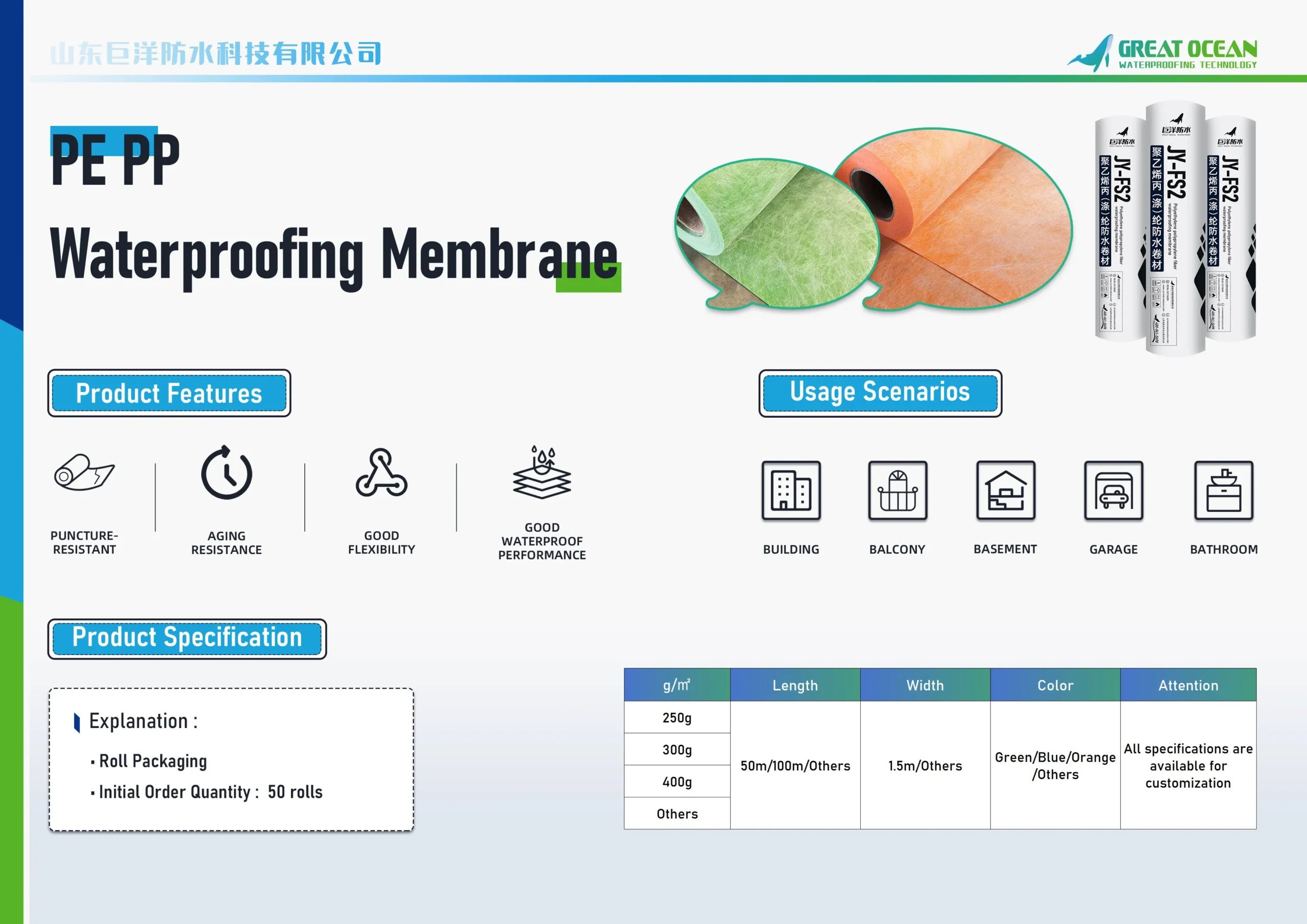

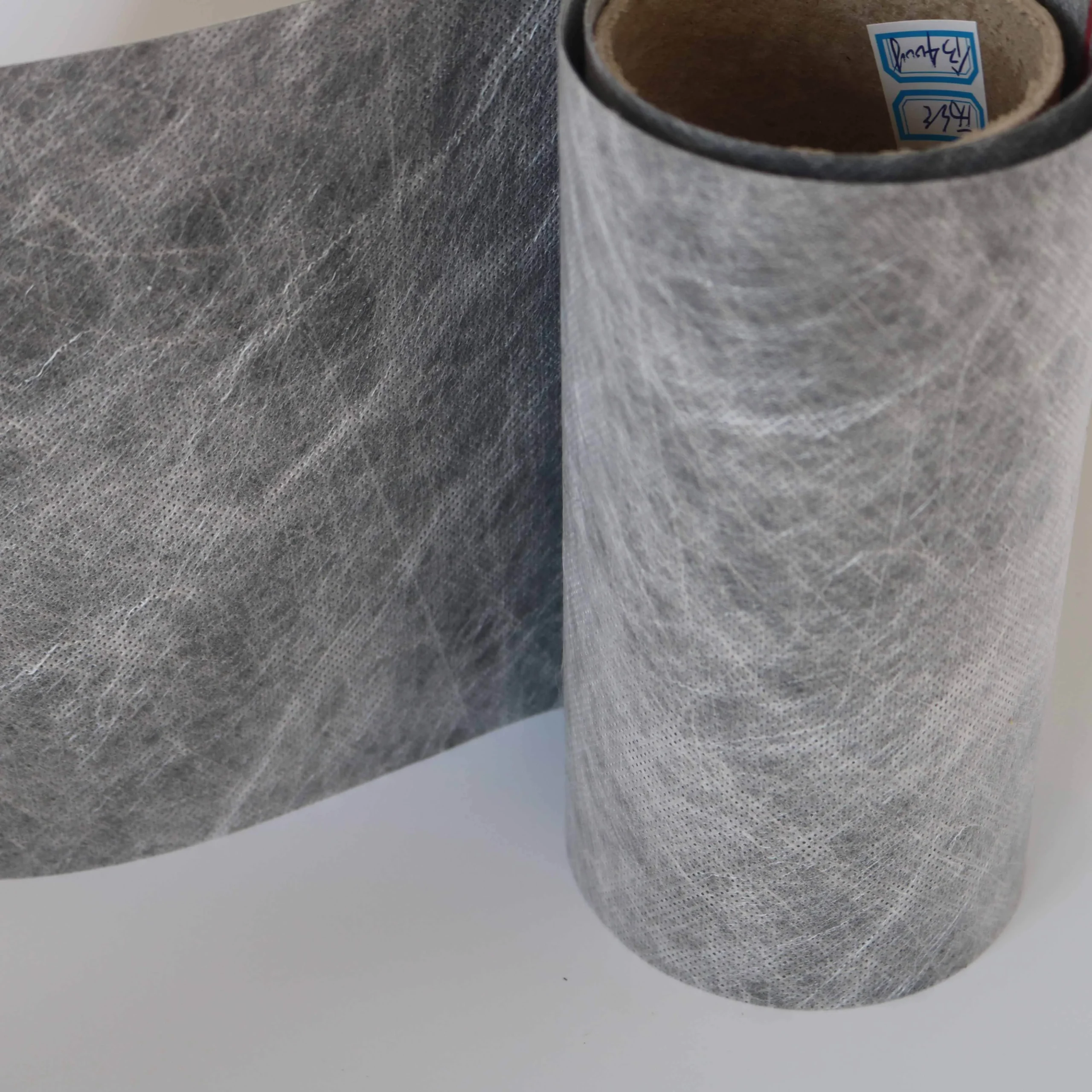

JY-GBL Polymer Waterproof Membrane PE PP Polyethylene Polypropylene Waterproofing Membrane

The JY-GBL Polymer Waterproof Membrane is a polyethylene polypropylene waterproofing membrane designed to meet modern engineering needs for waterproofing and anti-seepage applications. It consists of polyethylene, high-strength polypropylene or polyester fiber non-woven fabric, ultraviolet light barriers, anti-aging agents, and other macromolecular materials, produced through one-time extrusion using updated technology and equipment. As a manufacturer in China, our factory provides this product with standard pricing options available upon inquiry.

Pasiuna sa Produkto

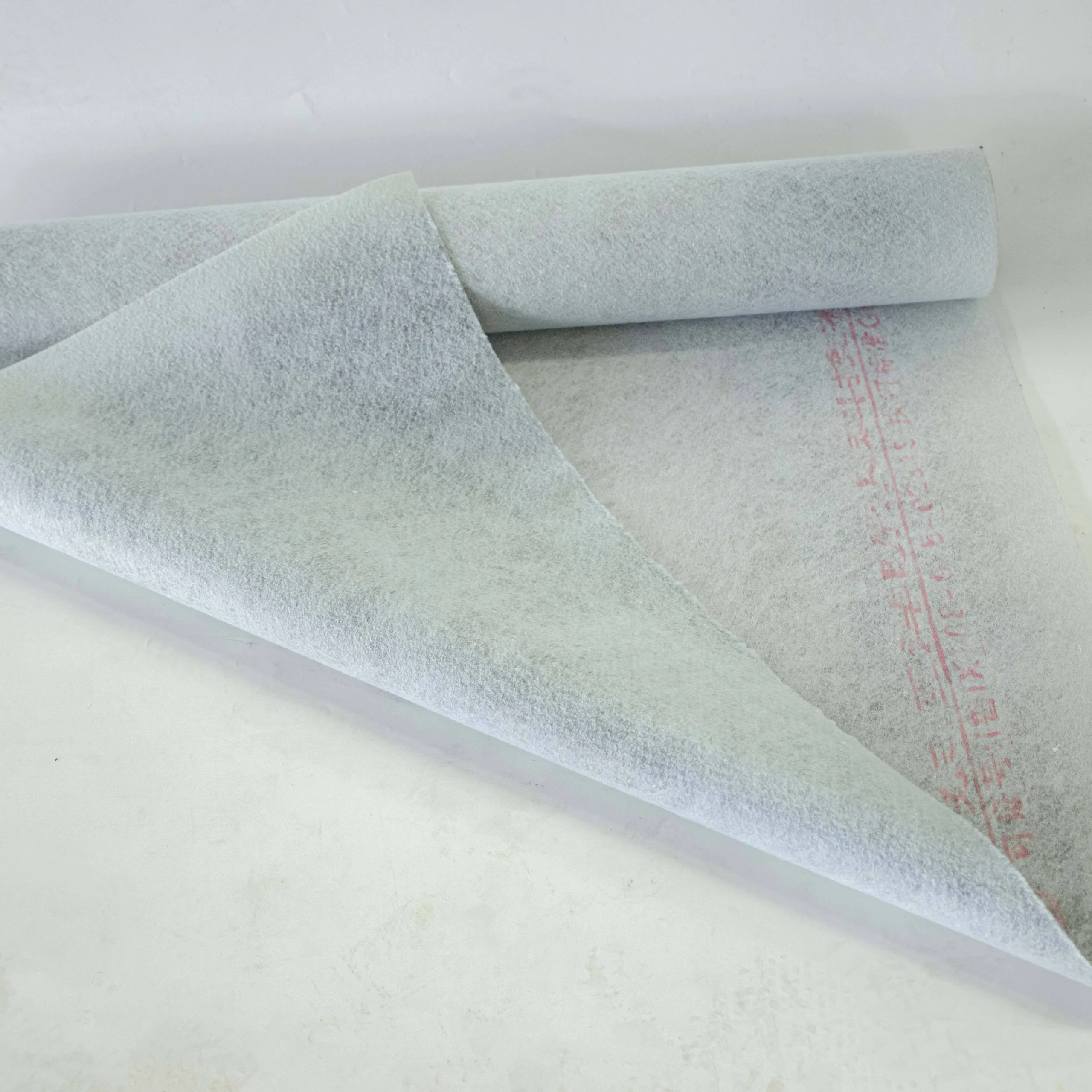

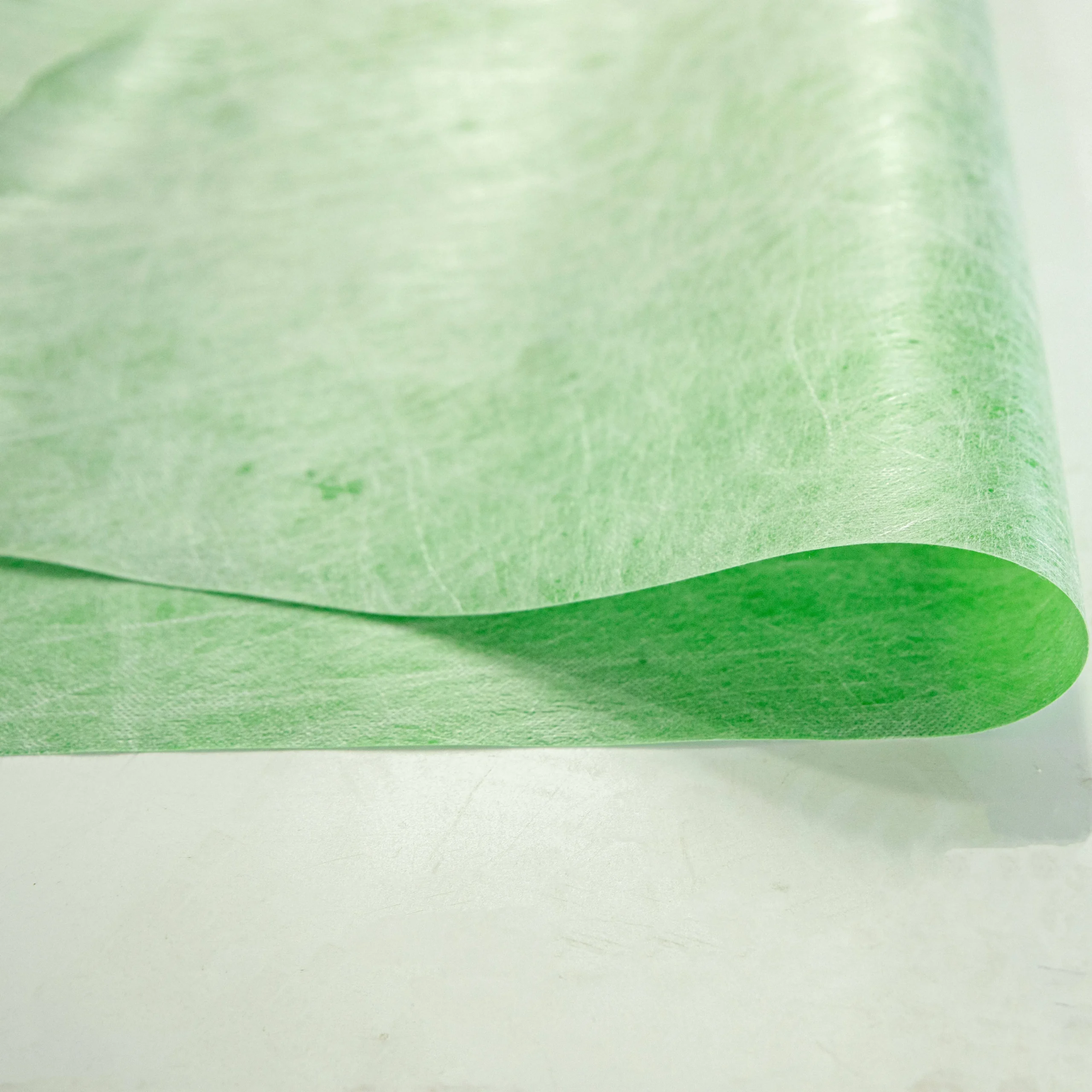

The JY-GBL Polymer Waterproof Membrane is a composite material consisting of polyethylene and polypropylene layers, developed as an extension of traditional waterproofing and anti-seepage products. It incorporates polyethylene as the core waterproof layer, combined with high-strength polypropylene or polyester fiber non-woven fabric on the surface, along with additives such as ultraviolet light barriers and anti-aging agents.

This membrane is produced through a one-time extrusion process using specialized equipment, resulting in a multi-layer structure that integrates the non-woven fabric surface with the polyethylene-polypropylene underface. Standard specifications include thicknesses ranging from 0.7 mm to 1.2 mm, lengths of 50 m or 100 m per roll, and a width of 1.2 m.

Common properties reported for similar polyethylene-polypropylene membranes include resistance to aging, weathering, and corrosion, as well as tensile strength suitable for construction applications. These materials are typically used in roofing, basements, bathrooms, tunnels, dams, and other civil or industrial projects requiring moisture protection and impermeability. Installation often involves direct bonding with cement or other substrates during construction.

Mga Kinaiya sa Produkto

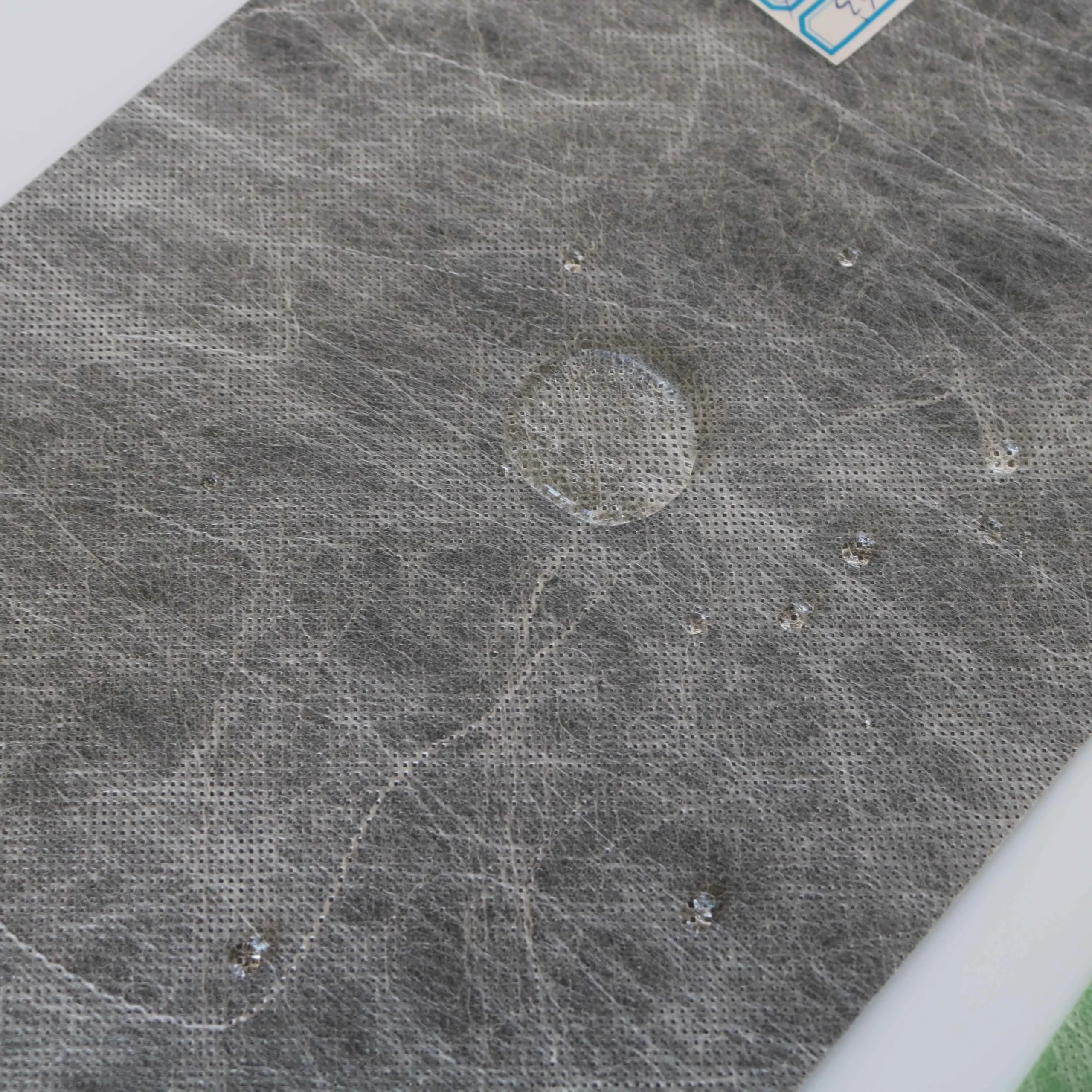

- Physical Properties: Exhibits anti-aging, anti-oxidation, and corrosion resistance. Offers flexibility for bending without breaking, along with tensile strength and resistance to perforation.

- Base Surface Compatibility: Requires minimal preparation; installation can proceed on damp surfaces without standing water. After rainfall, excess water can be removed to allow immediate construction, supporting faster project timelines.

- Puncture Resistance: Designed for use on green planting surfaces, providing resistance to punctures and the ability to prevent root penetration, which contributes to effective waterproofing.

- Composite Structure: Integrates with polymer cement bonding materials for use alongside coil materials, forming a system that supports environmental considerations.

- Environmental Attributes: Non-toxic, odorless, and free from pollution.

Additional properties based on similar polyethylene polypropylene membranes include UV stability for outdoor exposure, a multi-layer design with a waterproof core and protective layers, and a lifespan exceeding 50 years under typical conditions. These membranes maintain integrity across a temperature range, resisting cracking at low temperatures (down to -40°C) and deformation at high temperatures (up to +100°C), while providing strong adhesion to substrates.

Pagpasundayag

Mga Aplikasyon

- Mga Sistema sa Atop: Applied to flat, pitched, or green roofs in commercial and residential buildings to prevent leaks and moisture ingress.

- Mga Silong ug mga Istruktura sa Ilalom sa Yuta: Used for waterproofing foundations, walls, and floors in below-grade areas to protect against groundwater and seepage.

- Tunnels and Subways: Installed in transportation infrastructure like tunnels, subways, highways, railways, and culverts for impermeability and corrosion resistance.

- Bridges and Municipal Projects: Suitable for bridges and other civic engineering works requiring durability under deformation and environmental stress.

- Water Storage and Hydraulic Structures: Employed in tanks, reservoirs, dams, weirs, artificial lakes, swimming pools, channels, and irrigation systems to contain water and prevent leaks.

- Interior Wet Areas: Utilized in bathrooms, kitchens, balconies, toilets, and similar spaces for moisture-proofing surfaces.

- Above-Grade Exterior Areas: Applied to balconies, parking decks, rooftop terraces, and plazas where exposure to weather demands reliable barriers.

Installation Guide

This guide outlines the standard installation process based on the product's characteristics and common practices for similar polyethylene polypropylene composite membranes. Always follow local building codes, manufacturer specifications, and safety protocols. Tools typically required include a utility knife, rollers, trowels, and adhesive applicators. Ensure the substrate is structurally sound before beginning.

- Surface Preparation: Thoroughly clean the base surface to remove dirt, dust, debris, and any loose materials. Use a damp sponge or broom for cleaning. The surface should be free of oils, grease, or contaminants. For drywall or porous substrates, apply a compatible primer and allow it to dry fully. This step ensures proper adhesion and prevents issues during application.

- Primer or Adhesive Application: Prepare a polyurethane-based adhesive or polymer cement bonding material according to proportions specified (typically mixed on-site). Apply it evenly across the base layer using a trowel, focusing on complex areas such as corners, pipe roots, and edges. Allow the adhesive to tack up if required, but proceed while it's still fresh for bonding.

- Special Area Treatment: In vulnerable waterproofing zones like pipe penetrations, expansion joints, internal/external corners on grounds and walls, apply an additional layer of polyurethane coating or compatible sealant as reinforcement. For pipes, use pre-cut collars or seals if available; embed them into the adhesive. Cut the membrane to fit around these features, ensuring no gaps.

- Membrane Laying: Unroll the membrane starting from the lowest point or bottom edge, working upwards to avoid trapping air. Align it carefully and embed it into the adhesive using a roller or float to remove air pockets and ensure full contact. For walls or vertical surfaces, start at the base and overlap subsequent sheets. Maintain uniform thickness during placement.

- Joint and Overlap Handling: Overlap adjacent rolls by at least 2-6 inches (50-150 mm) to create secure seams. Temporarily fix overlaps with adhesive tape or spots of bonding material. Then, apply a specialized lap joint adhesive along the seams, followed by a sealant for final closure. Roll over the joints to ensure they are flat and watertight. Pay attention to end laps and penetrations for complete sealing.

- Finishing and Inspection: After installation, inspect for bubbles, wrinkles, or unsealed areas. Repair any defects immediately with additional membrane patches and sealant. Allow the system to cure as per adhesive instructions before applying finishes like tiles or backfill. In damp conditions, installation can proceed on non-puddled surfaces, but ensure no standing water.

- Post-Installation Notes: Protect the installed membrane from damage during subsequent construction. For tile applications, use unmodified or modified thin-set mortars directly over the membrane. Test for leaks if applicable, and store unused rolls in a dry, cool place.

Comparison: JY-GBL Polymer Waterproof Membrane (Polyethylene Polypropylene) vs. TPO Membranes

The JY-GBL is a composite waterproofing membrane made from polyethylene as the core layer with polypropylene or polyester non-woven fabric, additives for UV and aging resistance, and produced via extrusion. In contrast, TPO (Thermoplastic Polyolefin) membranes are typically single-ply sheets blending polypropylene and ethylene-propylene rubber, often reinforced with polyester scrim. While both serve waterproofing needs in construction, they differ in composition, performance, and typical uses. Below is a side-by-side comparison based on standard properties.

| Feature | JY-GBL PE/PP Membrane | TPO Membrane |

|---|---|---|

| Composition | Multi-layer composite: Polyethylene core, high-strength polypropylene/polyester non-woven fabric surface, with UV barriers and anti-aging agents. | Homogeneous blend: Polypropylene and ethylene-propylene rubber, usually with polyester reinforcement and no added plasticizers for flexibility. |

| Gibag-on | 0.7–1.2 mm. | Commonly 1.1–2.0 mm (45–80 mils). |

| Typical Lifespan | Up to 50+ years under normal conditions, with strong resistance to aging and weathering. | 15–30 years, depending on quality; newer formulations may vary, but some show degradation after 10–20 years. |

| Durability & Resistance | Good anti-aging, oxidation, corrosion, and puncture resistance; handles root penetration for green roofs; flexible without breaking; suitable for damp bases. | Strong initial UV and heat resistance; good puncture and tear strength; but can absorb oils/greases leading to breakdown; reflectivity may drop over time. |

| Pagsukol sa Kemikal | Corrosion-resistant; non-toxic and pollution-free. | Moderate; poor against greases, acids, or chemicals from exhausts; better in clean environments. |

| Temperature Range | Maintains integrity from -40°C to +100°C; resists cracking and deformation. | Performs well in heat but may degrade under extreme highs; flexible in moderate climates. |

| Pag-instalar | Bonds with polymer cement; can install on damp surfaces; overlaps sealed with adhesive; suitable for complex areas like pipes and corners. | Heat-welded seams; lightweight and easy to install; requires dry, clean surfaces; prone to seam issues if not done properly. |

| Mga Aplikasyon | Versatile: Roofs, basements, tunnels, bridges, water tanks, interiors (e.g., bathrooms), and green planting surfaces. | Primarily flat/low-slope roofs; common in commercial buildings for energy efficiency; less ideal for underground or wet areas. |

| Gasto | Generally economical for broad waterproofing needs; roll sizes (50/100 m length, 1.2 m width) support efficient coverage. | Often the lowest-cost single-ply option; but long-term replacement may add expenses. |

| Epekto sa Kalikopan | Non-toxic, odorless, pollution-free; recyclable components. | Recyclable; reflective surfaces aid energy savings, but some formulations rely on fire retardants. |

In summary, the JY-GBL PE/PP membrane offers broader application versatility and potentially longer service life in varied environments, while TPO excels in cost-effective roofing with reflective properties for cooling. Choice depends on project specifics like exposure to chemicals or installation conditions.

Mga Review sa Kustomer

John R., USA (Contractor, Basement Waterproofing Project)

I used this membrane for a basement retrofit in a humid area. It adhered well to the damp concrete without much prep, and after a year, no signs of seepage despite heavy rains. The rolls were straightforward to handle, though I needed extra adhesive for the overlaps. Solid choice for underground work, but plan for some trimming around pipes.

Elena S., Germany (Engineer, Tunnel Lining)

Applied this in a small tunnel project where corrosion resistance was key. The material held up during installation on uneven surfaces, and its puncture resistance helped with the rocky base. We've monitored it for six months—no issues with water ingress. It's not the cheapest option, but it performs as expected in industrial settings.

Michael T., Australia (Homeowner, Roof Application)

Installed this on my flat roof extension. It was flexible enough to conform to the contours, and the UV barrier seems to be doing its job under the sun. No leaks after recent storms, but I had to double-check the seams to ensure they were sealed properly. Good for outdoor exposure, though I'd recommend professional help for larger areas.

Aiko H., Japan (Builder, Water Storage Tank)

We used it for lining a municipal water tank. The non-toxic properties were important for compliance, and it bonded evenly with the polymer cement. After testing, it contained water without any deformation. Handling was easy, but the width limited coverage in tight spaces—had to order extra rolls.

Carlos M., Mexico (Landscaper, Green Roof System)

Put this under a rooftop garden to block root penetration. It worked fine against the plants' growth over eight months, and the anti-aging additives appear to maintain its integrity in hot weather. Installation went smoothly on the prepared surface, though overlaps required careful attention to avoid gaps. Reliable for planting applications.

About Our Factory: Great Ocean Waterproof

Company Overview

Great Ocean Waterproof Technology Co., Ltd. (formerly Weifang Great Ocean New Waterproof Materials Co., Ltd.) was established in 1999. Located in China's largest waterproof materials base in Tai Tou Town, Shouguang City, it is a high-tech enterprise specializing in waterproofing, integrating research and development, production, and sales.

Factory Details

The factory covers an area of 26,000 square meters. Over years of development and innovation, it has equipped multiple advanced production lines for membranes, sheets, and coatings at a domestic leading level.

Main Products

The company offers dozens of waterproofing products, including:

- Polyethylene polypropylene (polyester) polymer waterproof membrane

- Polyvinyl chloride (PVC) waterproof membrane

- Thermoplastic polyolefin (TPO) waterproof membrane

- High-speed rail dedicated chlorinated polyethylene (CPE) waterproof membrane

- Polymer polypropylene self-adhesive waterproof membrane

- Non-asphalt based reactive pre-applied polymer self-adhesive film waterproof membrane

- Strong cross-laminated film polymer reactive adhesive waterproof membrane

- Protective drainage board

- Elastomer/plastomer modified bitumen waterproof membrane

- Asphalt-based self-adhesive waterproof membrane

- Polymer modified bitumen root-resistant waterproof membrane

- Metal base polymer root-resistant waterproof membrane

- Root-resistant polymer polyethylene polypropylene (polyester) waterproof membrane

- Root-resistant polyvinyl chloride PVC waterproof membrane

- Single-component polyurethane waterproof coating

- Two-component polyurethane waterproof coating

- Polymer cement (JS) composite waterproof coating

- Water-based (951) polyurethane waterproof coating

- Polyethylene polypropylene (polyester) special dry powder adhesive

- Cement-based permeable crystalline waterproof coating

- Spray quick-setting rubber asphalt waterproof coating

- Non-curing rubber asphalt waterproof coating

- Exterior wall transparent waterproof glue

- High-elasticity liquid membrane waterproof coating

- Self-adhesive asphalt waterproof tape

- Butyl rubber self-adhesive tape

Technical Strength and Quality Assurance

The company boasts strong technical capabilities with a team of professional technicians, advanced equipment, and complete testing instruments. Products are stable and reliable, certified by national authoritative testing institutions. It has achieved the National Ministry of Agriculture's "Comprehensive Quality Management Standard" title and passed quality assurance system certification. Additionally, it holds designations such as "National Authoritative Testing Qualified Product" from the China Quality Inspection Association, Shandong Province's "Industrial Construction Product Filing Certificate," "Industrial Product Production License," and "CE Certification."

Market and Reputation

The company emphasizes contract compliance and credibility. Its products are sold in over 20 provinces and regions across China and exported to multiple countries and regions overseas, earning positive user feedback.

Business Philosophy

Great Ocean Waterproof Technology Co., Ltd. adopts a modern management mechanism, guided by the corporate spirit of "integrity, pragmatism, innovation" and the purpose of "win-win sharing." It provides high cost-performance products and quality services to collaborate with customers in expanding markets and creating new achievements.

![JY-ZSE Taas nga Elongasyon nga Self-Adhesive Waterproofing Membrane [e]](https://great-ocean-waterproof.com/wp-content/uploads/2025/12/JY-ZSE-High-Elongation-Self-Adhesive-Waterproofing-Membrane-e2_1-300x300.webp)