The evolution of moisture management in structural engineering has moved decisively toward high-performance synthetic polymers, with High-Density Polyethylene (HDPE) emerging as the gold standard for subterranean and critical infrastructure protection. As an expert from Great Ocean Waterproof, it is essential to analyze the technical superiority of the hdpe waterproofing membrane, a material that has redefined expectations for longevity, chemical resistance, and installation efficiency. Unlike traditional bituminous coatings that serve as simple surface barriers, HDPE systems represent a sophisticated engineering solution designed to integrate with the structural concrete itself. This integration is particularly vital in modern construction, where urban density requires deeper basements, more complex tunnel networks, and more resilient foundations that must withstand aggressive soil chemistry and high hydrostatic pressure for over half a century.

Chemical Composition and Structural Integrity of HDPE

To understand the efficacy of this material, one must look at the molecular level. High-Density Polyethylene is a thermoplastic polymer produced from the monomer ethylene. Through specific catalytic processes, such as the Ziegler-Natta or metallocene catalysts, the polymerization occurs under conditions that minimize chain branching.5 This linear structure allows the polymer chains to pack tightly, resulting in a high degree of crystallinity, typically ranging from 60% to 80%.5 The density of these membranes usually exceeds $0.941 g/cm^3$, which directly correlates to their superior tensile strength and impermeability.2

The physical properties of HDPE are characterized by a unique balance of rigidity and ductility. In structural applications, the membrane must be rigid enough to resist punctures from reinforcing steel and backfill aggregates, yet flexible enough to accommodate the natural settlement of the earth and the thermal expansion of the building.2 Furthermore, HDPE’s chemical inertness is a byproduct of its saturated hydrocarbon chain, which contains no polar groups that could react with acids, alkalis, or salts found in groundwater.5 This makes it a perfect waterproofing membrane for concrete structures located in former industrial sites or areas with high mineral content in the soil.

Advanced Mechanisms of the Fully Bonded System

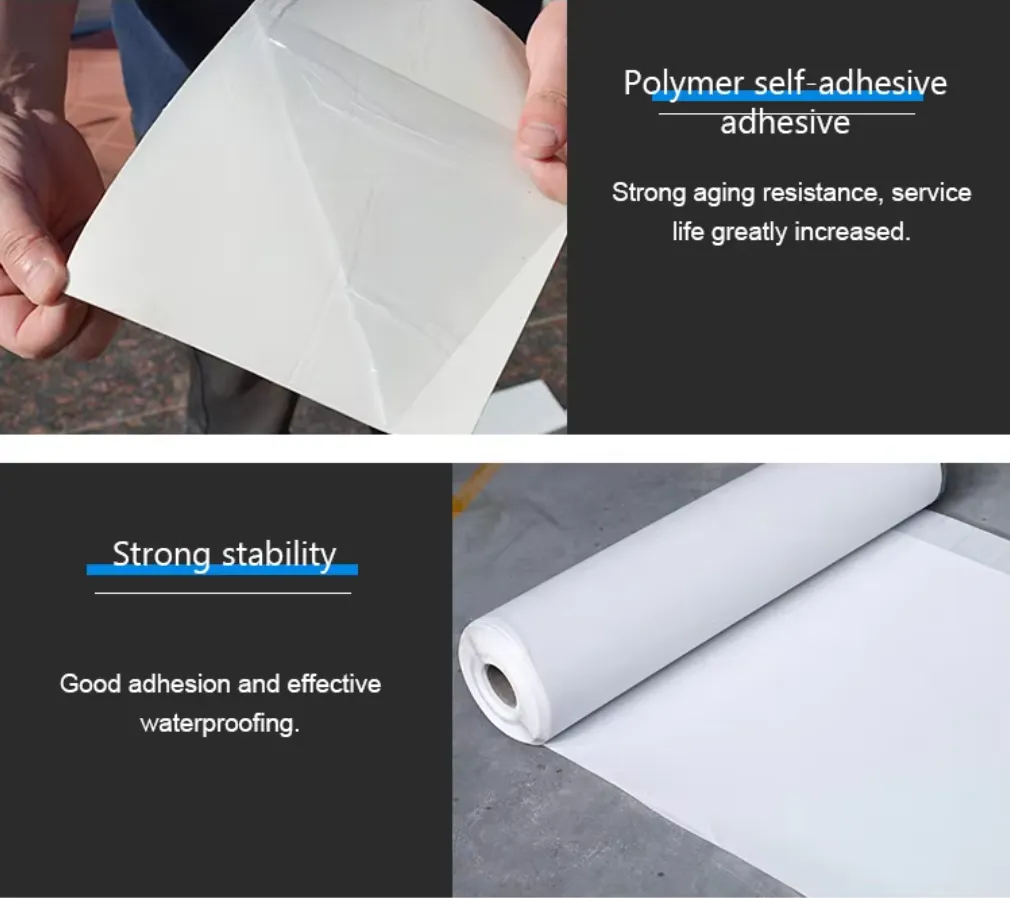

The primary technical challenge in traditional waterproofing is the phenomenon known as lateral water migration. If a traditional loose-laid or partially adhered membrane is punctured, water can travel freely between the membrane and the concrete surface, leading to leaks that are notoriously difficult to locate. The modern hdpe membrane waterproofing application utilizes a fully bonded technology to eliminate this risk. By employing a specialized pressure-sensitive adhesive (PSA) or a reactive fleece backing, the membrane creates a monolithic bond with the wet concrete as it cures.

This chemical and mechanical cross-linking ensures that the membrane and the structural slab become a single unit. The active ingredients in the adhesive layer react with the silicates in the pouring concrete, forming an irreversible bond that exceeds the cohesive strength of the concrete itself. Consequently, even if the membrane is physically breached by a major seismic event or mechanical accident, the water remains trapped at the point of entry and cannot migrate across the foundation, significantly simplifying repair processes and protecting the structural reinforcement from corrosion.

| Feature | HDPE Fully Bonded System | Traditional Loose-Laid System |

| Water Migration | Prevented by integral bond | Common through gaps |

| Installation Phase | Pre-applied before concrete | Post-applied after curing |

| Bond Strength | High (Chemical/Mechanical) | Low (Mechanical/None) |

| Longevity | 50+ Years | 10-20 Years |

| Chemical Resistance | Exceptional | Variable |

| Substrate Prep | Can be laid on damp base | Requires dry surface |

Comparative Analysis of Polymer Waterproofing Technologies

While HDPE is the premier choice for below-grade applications, the broader waterproofing market includes several other thermoplastic and elastomeric materials. A thorough understanding of these alternatives is necessary for professional peer evaluation. For instance, the tpo waterproofing membrane (Thermoplastic Polyolefin) is highly regarded in the roofing sector for its solar reflectivity and heat-weldable seams. TPO combines the weather resistance of EPDM rubber with the weldability of polypropylene, making it an excellent choice for exposed environments.

In contrast, the pvc waterproofing membrane has been a staple in the industry for decades due to its extreme flexibility and resistance to fire. However, the pvc waterproofing membrane application often requires the inclusion of plasticizers to maintain its flexibility, which can leach out over time, especially when in contact with certain soil chemicals, potentially leading to embrittlement. For foundations and tunnels where the material is buried and inaccessible for maintenance, the plasticizer-free nature of HDPE provides a more stable long-term solution.

Furthermore, for vertical applications and complex geometries where sheet membranes are difficult to detail, many engineers specify a polyurethane waterproof coating for roof or balcony protection. These liquid-applied systems provide a seamless finish and excellent adhesion to diverse substrates. However, liquid coatings require precise climatic conditions for curing and are susceptible to application errors in thickness. In high-hydrostatic-pressure environments below grade, the factory-controlled thickness of an HDPE sheet remains the superior choice for consistent performance.

Detailed Engineering Applications: Foundation and Concrete Protection

The implementation of a waterproofing membrane for foundation projects requires a multi-layered approach to ensure structural dry-proofing. Great Ocean Waterproof focuses on the strategic deployment of materials based on site-specific risks such as water table levels and soil composition. In high-water-table areas, a two-ply system or a self adhesive waterproofing membrane with a cross-laminated HDPE film is often recommended for added safety.

For pre-applied scenarios—often referred to as blindside waterproofing—the membrane is installed against the soil retention system (such as secant piles or sheet piling) before the reinforcement steel and concrete are placed. This method is essential for urban construction where excavation is limited. The best self adhesive hdpe waterproofing membrane for these projects typically features a grit or sand finish to protect the adhesive layer from foot traffic and to enhance the mechanical interlock with the poured concrete.

In the post-applied context, the membrane is fixed to the exterior of a cured concrete wall. This is common in residential basements where there is sufficient room for excavation. Here, the hdpe membrane waterproofing application involves cleaning the cured concrete, applying a compatible primer, and then rolling out the self-adhesive sheets. The use of a drainage board or dimple mat over the membrane is a best practice, as it provides a pathway for water to reach the footer drains and protects the HDPE from abrasion during the backfilling process

Technical Nuances of Modified Bitumen and Elastomeric Systems

While synthetic polymers represent the future, traditional bituminous systems like sbs waterproofing membrane and app membrane waterproofing still play a role in the global market. SBS (Styrene-Butadiene-Styrene) modified bitumen is essentially “rubberized asphalt,” which remains flexible at extremely low temperatures, making it suitable for arctic climates. On the other hand, APP (Atactic Polypropylene) modified bitumen is “plasticized asphalt,” which has a higher melting point and better UV resistance, making it ideal for tropical roofing applications.

However, when compared to the 50-year design life of an HDPE system, a bitumen waterproofing membrane typically offers a service life of 15 to 25 years. Bituminous membranes are also prone to oxidative hardening and can be damaged by roots in planted roof scenarios, whereas HDPE is inherently root-resistant. For a comprehensive waterproofing membrane for roof design, engineers must weigh the lower initial cost of bitumen against the lifecycle cost savings and environmental benefits of higher-performance polymers.

Installation Excellence and Quality Control Protocols

The effectiveness of even the highest-grade HDPE material is compromised by poor installation. At Great Ocean Waterproof, we emphasize a rigorous protocol for the hdpe membrane waterproofing application to ensure zero-leak performance. The process begins with substrate preparation, where the mud slab or retention wall must be cleared of standing water, sharp stones, and debris.

Seam management is the most critical phase. Modern HDPE membranes are joined using either dual-track heat welding or specialized adhesive selvedges. Heat welding creates a fusion bond that is physically inseparable, and the dual-track method allows for air-pressure testing of the seam to verify its integrity. For details around penetrations such as pipes, conduits, and pile heads, specialized detail tapes and liquid flashings are used to maintain the continuity of the barrier.

| Step | Action | Critical Requirement |

| Preparation | Surface cleaning and leveling | No protrusions > 5mm |

| Layout | Unrolling and aligning sheets | 75mm to 100mm overlaps |

| Seaming | Heat welding or adhesive bonding | Consistent temperature and pressure |

| Detailing | Flashing around penetrations | Use of compatible sealants |

| Inspection | Visual and air-pressure testing | 100% seam verification |

| Protection | Placement of drainage boards | Avoid damage during backfill |

Environmental Sustainability and Regulatory Compliance

HDPE is widely recognized as one of the most environmentally friendly plastics available for construction. It is highly recyclable (Resin Code 2) and does not contain the phthalates or heavy metals often found in other synthetic barriers. Furthermore, because it is chemically inert and does not degrade in the soil, it poses no risk of groundwater contamination.

Great Ocean Waterproof products are manufactured in compliance with international standards such as ASTM and ISO, ensuring that every roll of hdpe waterproofing membrane meets the necessary requirements for tensile strength, elongation, and hydrostatic resistance. Our commitment to innovation and pragmatism allows us to provide solutions that not only protect the building but also support the broader goal of sustainable infrastructure development.

The Strategic Choice for Modern Construction

Choosing the right waterproofing system is a decision that impacts the entire lifecycle of a building. The HDPE membrane stands out as the most reliable, durable, and cost-effective solution for deep foundations, tunnels, and critical infrastructure. Its ability to form a permanent, monolithic bond with concrete, coupled with its extreme chemical resistance and 50-year lifespan, makes it the preferred choice for engineers and developers worldwide.

At Great Ocean Waterproof, we provide a one-stop service for waterproofing system solutions, from research and manufacturing to technical support on the job site. Our expertise in high-performance polymers ensures that your project is protected by the most advanced technology in the industry. For more detailed specifications and to find the ideal solution for your specific project needs, please visit our official website at http://great-ocean-waterproof.com/. Investing in superior waterproofing today is the only way to ensure the structural integrity and value of your assets for the decades to come.