When it comes to protecting buildings from water damage, choosing the right waterproofing material can make the difference between decades of reliable protection and costly repairs. SBS waterproofing membrane has emerged as one of the most trusted solutions in the construction industry, offering superior flexibility, durability, and performance across diverse climates and applications.

Understanding SBS Waterproofing Membrane

SBS waterproofing membrane is a modified bitumen sheet that incorporates Styrene-Butadiene-Styrene (SBS) polymers into asphalt to create a highly elastic and weather-resistant waterproofing material. This synthetic rubber modification fundamentally transforms traditional bitumen’s properties, resulting in a membrane that maintains flexibility even in extreme temperatures while providing exceptional waterproofing capabilities.

The development of SBS-modified bitumen represents a significant advancement in waterproofing technology. Unlike conventional asphalt-based membranes that can become brittle in cold weather and soften excessively in heat, SBS membranes maintain consistent performance across temperature ranges from -25°C to 100°C (-13°F to 212°F). This remarkable temperature stability makes SBS membranes suitable for virtually any climate zone worldwide.

The Science Behind SBS Modification

The SBS polymer creates a three-dimensional network within the bitumen matrix, fundamentally altering its physical properties. This molecular structure allows the membrane to stretch and recover without losing its waterproofing integrity. When stress is applied, the elastic polymer chains extend and then return to their original configuration once the stress is removed, preventing permanent deformation and cracking that would compromise waterproofing performance.

This elastic recovery capability is particularly valuable in situations where buildings experience thermal expansion and contraction, structural settling, or vibration. Traditional waterproofing materials often fail at movement joints or where substrates undergo dimensional changes, but SBS membranes accommodate these movements while maintaining a continuous waterproof barrier.

Composition and Manufacturing Process

SBS waterproofing membranes typically consist of multiple layers working together to deliver comprehensive protection. The core layer contains SBS-modified bitumen, which provides the primary waterproofing function and elastic properties. This modified bitumen is reinforced with a carrier material—usually polyester fabric, fiberglass, or a composite combination of both materials.

Reinforcement Materials and Their Roles

Polyester reinforcement offers superior elongation properties, allowing the membrane to stretch significantly without tearing. This makes polyester-reinforced SBS membranes ideal for applications where substrate movement is expected or where the membrane must bridge small cracks. The fiber structure of polyester also provides excellent dimensional stability and tensile strength in all directions.

Fiberglass reinforcement, while less elastic than polyester, provides exceptional dimensional stability and resistance to tearing. Fiberglass-reinforced membranes are often preferred for applications requiring minimal dimensional change, such as torch-applied installations where precise positioning is critical. Some high-performance SBS membranes utilize composite reinforcement that combines polyester and fiberglass to capture the benefits of both materials.

The top surface of SBS membranes typically features a protective layer that varies depending on the intended application. For exposed applications, the top surface may incorporate ceramic granules, mineral slate, or reflective coatings that protect the underlying bitumen from UV radiation while providing aesthetic appeal. For concealed applications beneath pavers or additional roofing layers, the top surface might feature a sand coating or polyethylene film that facilitates bonding with subsequent layers.

The bottom surface usually includes a release film or sand coating that protects the membrane during storage and transportation while facilitating proper installation. Self-adhered SBS membranes feature a specially formulated adhesive layer protected by a removable release liner, eliminating the need for heat application during installation.

Key Properties and Performance Characteristics

The unique composition of SBS waterproofing membranes delivers several critical performance characteristics that set them apart from alternative waterproofing solutions.

Exceptional Flexibility and Elasticity

SBS membranes can elongate by 500% or more without breaking, allowing them to accommodate significant substrate movement without compromising waterproofing integrity. This flexibility remains consistent across temperature extremes, ensuring reliable performance whether installed in arctic conditions or tropical climates. The elastic memory of SBS polymers means the membrane returns to its original dimensions after stress is removed, preventing the formation of stress points that could lead to failure.

Superior Low-Temperature Performance

One of the most significant advantages of SBS modification is the membrane’s ability to remain flexible at temperatures where conventional bitumen becomes brittle and prone to cracking. This low-temperature flexibility is crucial for buildings in cold climates, where thermal cycling can cause repeated expansion and contraction. SBS membranes maintain their waterproofing seal and accommodate these movements without developing the stress cracks that plague less flexible materials.

Excellent Aging Resistance

The polymer modification of SBS membranes significantly enhances their resistance to oxidation, UV radiation, and thermal aging. While unmodified bitumen deteriorates relatively quickly when exposed to oxygen and sunlight, SBS-modified bitumen maintains its physical properties and waterproofing effectiveness for decades. Many SBS membrane systems carry warranties of 15 to 25 years, with actual service lives often exceeding these periods when properly installed and maintained.

Strong Adhesion Properties

SBS membranes develop robust adhesion to various substrates, including concrete, masonry, wood, metal, and existing waterproofing systems. This strong bond ensures the membrane remains securely attached even under challenging conditions such as wind uplift, ponding water, or hydrostatic pressure. The adhesion characteristics can be further enhanced through proper surface preparation and the use of compatible primers.

Types and Applications of SBS Waterproofing Membranes

SBS waterproofing technology has evolved to address diverse waterproofing challenges, resulting in several specialized membrane types suited to specific applications.

Torch-Applied SBS Membranes

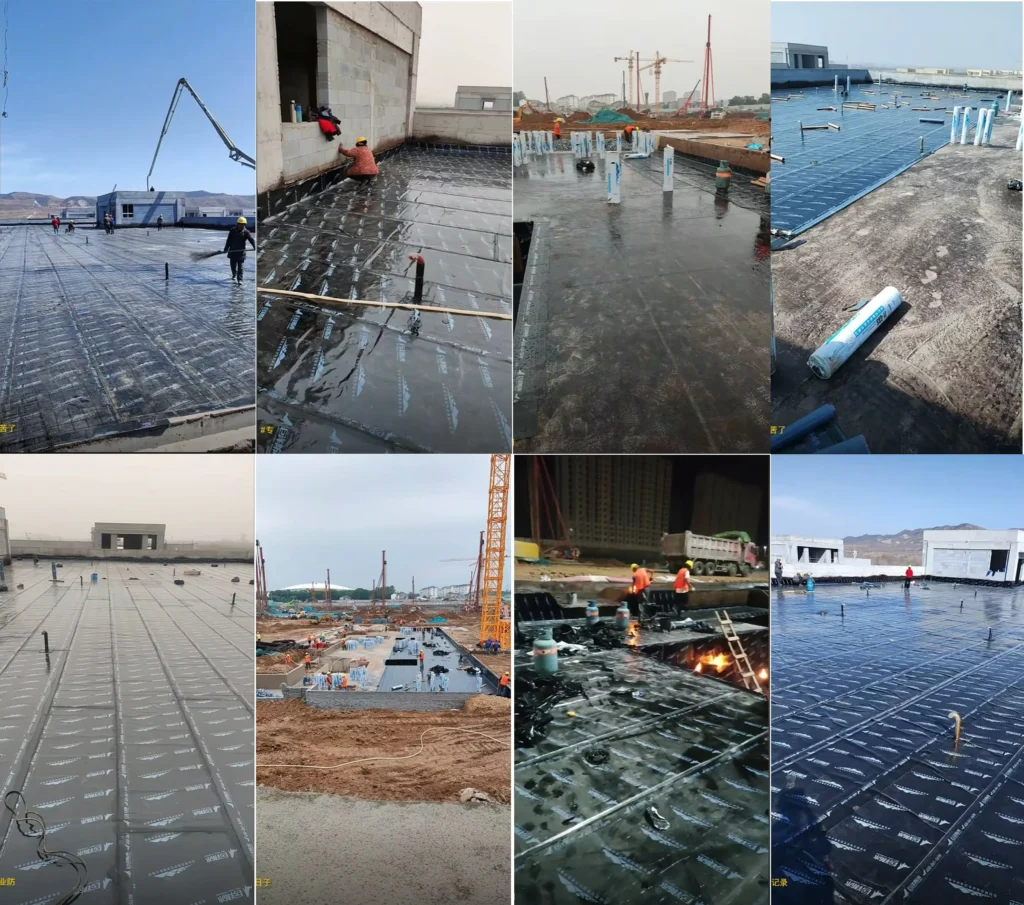

Torch-applied membranes remain the most common type of SBS waterproofing system worldwide. These membranes feature a thermoplastic film on the bottom surface that melts when heated with a propane torch, creating a strong bond with the substrate or previous membrane layer. The installation process requires skilled applicators who carefully control the heating process to achieve proper fusion without damaging the membrane or creating fire hazards.

Torch application provides several advantages, including strong adhesion, reliable seam fusion, and the ability to install in cooler weather conditions. The visual confirmation of proper fusion—indicated by the melted bitumen forming a small bead along the membrane edge—helps ensure quality installation. However, torch application is prohibited in certain locations due to fire safety concerns and requires appropriate safety measures and experienced installers.

Self-Adhered SBS Membranes

Self-adhered SBS membranes incorporate a pressure-sensitive adhesive layer protected by a removable release liner. These membranes eliminate the need for heat application, making them suitable for occupied buildings, fire-restricted areas, or projects where torch work is impractical. The installation process is generally safer and faster than torch application, though it requires careful attention to substrate preparation and proper rolling pressure to achieve adequate adhesion.

Modern self-adhered SBS membranes feature advanced adhesive formulations that provide strong initial tack and develop full bond strength over time. Some formulations include “split-release” systems that allow for temporary repositioning during installation, improving installation quality and reducing waste. Self-adhered membranes are particularly popular for vertical applications, detail work, and projects requiring minimal disruption.

Cold-Applied SBS Membranes

Cold-applied SBS membrane systems utilize liquid adhesives or asphaltic mastics to bond the membrane to the substrate. These systems offer advantages in temperature-sensitive environments or where open-flame work is prohibited. The liquid-applied adhesive layers can also help bridge minor substrate irregularities and provide additional waterproofing redundancy.

Installation of cold-applied systems typically involves coating the substrate with the appropriate adhesive, allowing it to reach the proper tack level, then rolling the membrane into the wet adhesive. This method requires careful timing and attention to environmental conditions, as temperature and humidity affect adhesive performance. Cold-applied systems are often selected for renovation projects or applications where noise, odor, or fire restrictions make other installation methods impractical.

Common Applications in Construction

SBS waterproofing membranes serve critical waterproofing functions across virtually every building type and construction application.

Roofing Systems

SBS membranes are extensively used in both low-slope and steep-slope roofing applications, providing reliable waterproofing protection for residential, commercial, and industrial buildings. On low-slope roofs, SBS membranes typically function as the primary waterproofing layer in built-up roofing (BUR) systems or as single-ply solutions in modified bitumen roofing assemblies.

The multilayer installation common in SBS roofing systems provides redundancy that enhances waterproofing reliability. A typical system might include a base sheet mechanically fastened or adhered to the roof deck, one or more interply sheets to build up thickness and provide additional waterproofing layers, and a cap sheet with a granule or reflective coating to protect against UV radiation and weathering.

SBS membranes accommodate the thermal movement inherent in roofing systems, expanding and contracting with temperature changes without developing leaks at seams or penetrations. This flexibility is particularly valuable around roof equipment, vent pipes, skylights, and other details that represent common leak points in rigid waterproofing systems.

Below-Grade Waterproofing

Foundation and below-grade waterproofing represents another critical application for SBS membranes. When installed on foundation walls, basement floors, or underground structures, SBS membranes create a continuous waterproof barrier that resists hydrostatic pressure from groundwater while accommodating structural movements caused by settling or thermal changes.

Below-grade SBS membrane systems typically incorporate multiple layers for enhanced reliability, often including a primer coat to improve adhesion, one or more SBS membrane layers for waterproofing, and a protection layer to prevent damage during backfilling. The elastic properties of SBS membranes make them particularly effective at maintaining waterproofing integrity across construction joints, penetrations, and transitions where rigid waterproofing systems might crack or separate.

The installation sequence for below-grade applications requires careful attention to drainage plane positioning, ensuring the waterproofing membrane remains in contact with the structure while allowing water to drain away through perimeter drainage systems. Protection boards, drainage composites, or insulation layers typically cover the membrane before backfilling to prevent puncture or damage during construction and throughout the building’s service life.

Plaza Decks and Balconies

Occupied plaza decks, parking structures, balconies, and terraces present unique waterproofing challenges, combining exposure to weathering, pedestrian traffic, drainage considerations, and the need for long-term reliability. SBS membranes excel in these applications, providing robust waterproofing beneath protective layers of pavers, tiles, or topping slabs.

The installation typically includes careful detailing at drains, parapets, and penetrations, with the SBS membrane extending up vertical surfaces to create a continuous waterproofing envelope. Proper drainage design remains critical, ensuring water moves efficiently off the membrane surface and preventing ponding that could lead to premature membrane degradation or leakage through unsealed joints.

Many plaza deck systems incorporate additional protection and drainage layers above the SBS membrane, including protection boards to prevent damage during installation of overburden materials, drainage composites to facilitate water movement, and insulation layers for thermal performance. The flexibility of SBS membranes accommodates movement joints in the deck structure while maintaining waterproofing continuity through properly designed and installed detail components.

Tunnel and Underground Structure Waterproofing

Tunnels, underground parking facilities, subway systems, and other underground infrastructure require waterproofing systems capable of resisting sustained hydrostatic pressure while accommodating structural movements and tolerating challenging installation conditions. SBS membranes, particularly heavy-duty formulations with reinforced construction, provide effective waterproofing for these demanding applications.

Installation methods for tunnel waterproofing vary based on project specifics but often include torch-applied systems that provide reliable adhesion even in damp conditions. The continuous membrane application creates a seamless waterproof barrier that directs water to drainage systems, preventing infiltration that could compromise structural integrity or create operational problems.

Proper surface preparation becomes particularly critical in underground applications, as substrate defects or contamination can compromise membrane adhesion and waterproofing effectiveness. Detailed quality control procedures, including adhesion testing and continuous inspection during installation, help ensure waterproofing system reliability in these critical applications.

Installation Methods and Best Practices

Successful SBS membrane installation requires careful planning, proper surface preparation, skilled workmanship, and attention to detail throughout the process.

Surface Preparation Requirements

The substrate must be clean, dry, structurally sound, and free from contaminants that could prevent proper membrane adhesion. Concrete substrates should be fully cured, with any honeycombing, bug holes, or surface defects repaired using appropriate patching materials. Sharp edges, protrusions, or abrupt transitions should be beveled or smoothed to prevent membrane damage.

Oil, grease, form release agents, curing compounds, and other bond-breaking contaminants must be completely removed through mechanical cleaning, solvent washing, or other approved methods. The substrate should be examined for excessive moisture, which can prevent proper adhesion and lead to blistering or delamination. Moisture testing using calcium chloride tests, plastic sheet tests, or electronic moisture meters helps verify the substrate is sufficiently dry for membrane application.

Primer application typically follows surface preparation, serving multiple functions including dust binding, pore sealing, and adhesion enhancement. The primer type should be compatible with both the substrate and membrane system, with application rates and drying times following manufacturer specifications. Some specialized primers include asphalt emulsions, solvent-based asphaltic primers, or two-component epoxy primers selected based on substrate type and project requirements.

Installation Techniques for Different Membrane Types

Torch-applied installation requires systematic heating of the membrane underside using a propane torch, melting the bottom film to create fusion with the substrate or underlying membrane layer. The installer unrolls the membrane while applying heat, carefully controlling the torch temperature and distance to achieve proper fusion without overheating or damaging the membrane. Proper overlap—typically 75-100mm (3-4 inches) at side laps and 150mm (6 inches) at end laps—ensures waterproofing continuity, with careful attention to achieving full fusion at all seams.

Self-adhered membrane installation begins with removing the release liner and carefully positioning the membrane on the prepared substrate. Firm rolling with a weighted roller ensures complete adhesion and eliminates air pockets that could compromise bonding. The installer must work systematically to avoid wrinkles or bridging and should pay particular attention to overlap seams, which may require heat sealing or liquid sealant application for full waterproofing integrity.

Cold-applied systems require coating the substrate with the specified adhesive, allowing it to reach the proper consistency (typically tacky but not wet), then carefully rolling the membrane into the adhesive. The installer must monitor environmental conditions, as temperature and humidity significantly affect adhesive performance and working time. Proper overlap treatment and seam sealing follow manufacturer specifications for the specific system being installed.

Critical Details and Transitions

Penetrations, terminations, inside and outside corners, and transitions between horizontal and vertical surfaces represent critical waterproofing details that require careful execution to prevent leaks. These areas typically receive additional reinforcement through extra membrane layers, fabric reinforcement, or specialized detail components.

At pipe penetrations, the membrane is carefully cut and fitted around the pipe, with supplementary flashing pieces overlapping the field membrane to create a waterproof seal. Termination bars, surface-mounted counterflashing, or reglet systems secure membrane terminations at walls, parapets, or equipment curbs while preventing water infiltration behind the membrane.

Inside corners typically receive reinforcing membrane strips before field membrane application, while outside corners may require careful folding and reinforcement to prevent stress concentration. Transitions from horizontal to vertical surfaces should follow manufacturer details for the specific system, usually involving careful membrane positioning to avoid bridging or air pockets that could compromise waterproofing.

Advantages Over Alternative Waterproofing Systems

SBS waterproofing membranes offer distinct advantages compared to other waterproofing technologies, making them the preferred choice for many applications.

Comparison with APP Modified Bitumen

While both SBS and APP (Atactic Polypropylene) modified bitumen membranes offer improved performance over conventional bitumen, SBS membranes provide superior flexibility, especially at low temperatures. APP membranes offer better flow resistance at high temperatures but lack the elastic recovery that makes SBS membranes particularly effective at accommodating substrate movement.

The installation characteristics also differ significantly. SBS membranes can be installed using multiple methods (torch-applied, self-adhered, or cold-applied), while APP membranes are primarily torch-applied. This versatility makes SBS systems adaptable to a wider range of project constraints and requirements.

Comparison with Single-Ply Membranes

Single-ply synthetic membranes like TPO, PVC, or HDPE offer lightweight installation and factory-controlled thickness but typically provide waterproofing through a single layer, lacking the redundancy of multi-ply SBS systems. Single-ply systems also rely heavily on seam integrity, with heat-welded or adhesive-bonded seams representing potential weak points.

SBS membranes develop self-healing properties due to the thermoplastic nature of the modified bitumen, allowing small punctures to seal under heat or pressure. Single-ply membranes lack this characteristic, with any puncture or seam failure potentially leading to water infiltration. The thicker cross-section of multi-ply SBS systems also provides greater resistance to impact damage and puncture.

Comparison with Liquid-Applied Membranes

Liquid-applied waterproofing systems offer advantages for complex geometries and can be applied quickly over large areas, but achieving consistent thickness and avoiding thin spots requires skilled application and favorable environmental conditions. SBS membranes provide guaranteed thickness and consistent quality through factory manufacturing, with installation primarily affecting adhesion rather than fundamental waterproofing properties.

The multilayer construction possible with SBS systems creates inherent redundancy that single-layer liquid applications cannot match without multiple coats, which increases installation time and cost. SBS membranes also offer superior puncture resistance and durability compared to most liquid-applied systems, particularly in high-traffic applications.

Maintenance and Expected Service Life

Properly installed SBS waterproofing membranes require minimal maintenance but benefit from periodic inspection to maximize service life and prevent minor issues from developing into significant problems.

Inspection and Maintenance Procedures

Regular inspections should examine the membrane surface for signs of damage, including punctures, tears, or separation at seams and terminations. Granulated cap sheets should be checked for granule loss that might expose the underlying bitumen to UV radiation. Drainage systems require periodic cleaning to ensure proper function and prevent ponding water that could accelerate membrane deterioration.

Any identified damage should be repaired promptly using compatible materials and proper techniques. Small punctures can typically be sealed using compatible mastic or patches, while larger damage might require cutting out and replacing the affected membrane section. Seam separations should be heat-welded or adhered using appropriate methods for the specific membrane type.

Factors Affecting Service Life

When properly installed and maintained, SBS waterproofing membranes typically provide 20 to 30 years of reliable service, with some systems exceeding 40 years in favorable conditions. Service life depends on multiple factors, including climate conditions, UV exposure, traffic loads, substrate movement, and installation quality.

Membranes with adequate UV protection through granule surfacing, reflective coatings, or protective overburden generally outlast exposed membranes without such protection. Proper drainage design that prevents prolonged water ponding also extends service life by reducing moisture exposure and thermal cycling effects. Buildings with minimal structural movement and stable substrates place less stress on the membrane, promoting longevity.

Selecting the Right SBS Membrane for Your Project

Choosing the appropriate SBS membrane system requires consideration of multiple project-specific factors to ensure optimal performance and cost-effectiveness.

Climate and Environmental Considerations

Extreme temperature ranges, UV exposure levels, precipitation patterns, and freeze-thaw cycling all influence membrane selection. Projects in cold climates benefit from membranes formulated for enhanced low-temperature flexibility, while hot climates may require reflective cap sheets or specialized formulations that resist flow at elevated temperatures.

High-altitude locations with intense UV radiation should utilize membranes with enhanced UV protection, such as ceramic granule surfacing or reflective coatings. Coastal environments subject to salt spray may require membranes with enhanced corrosion resistance for any metal components and careful attention to termination details that prevent water infiltration.

Structural and Loading Considerations

The expected substrate movement, building type, and anticipated loads influence membrane reinforcement selection and system design. Structures subject to significant movement, such as lightweight metal deck roofs or buildings on expansive soils, benefit from polyester-reinforced membranes that can accommodate greater elongation without tearing.

High-traffic applications like plaza decks or parking structures require heavy-duty membranes with enhanced puncture resistance and typically include substantial protection layers above the waterproofing membrane. Lightweight structures with load limitations might favor thinner membrane assemblies or self-adhered systems that eliminate the weight of torch-applied installation components.

Budget and Lifecycle Cost Analysis

While initial material and installation costs factor into membrane selection, lifecycle cost analysis provides a more complete picture by considering expected service life, maintenance requirements, energy performance, and replacement costs. Higher-quality SBS membranes with enhanced UV protection and heavier reinforcement typically carry higher initial costs but often provide lower lifecycle costs through extended service life and reduced maintenance.

Self-adhered systems may carry higher material costs compared to torch-applied membranes but can offer lower total installation costs when considering labor efficiency and safety factors. Cold-applied systems might be cost-competitive in specific situations despite higher material costs when project constraints make other installation methods impractical.

Why Great Ocean Waterproof Recommends SBS Technology

At Great Ocean Waterproof, we’ve witnessed firsthand how SBS waterproofing membranes consistently deliver superior performance across diverse applications and challenging environments. Our experience has shown that the combination of flexibility, durability, and proven reliability makes SBS technology an excellent choice for projects ranging from residential renovations to large-scale commercial developments.

The versatility of SBS systems allows us to tailor waterproofing solutions to specific project requirements, whether that means torch-applied systems for maximum adhesion, self-adhered membranes for fire-restricted areas, or cold-applied solutions for occupied buildings. This adaptability ensures we can provide effective waterproofing regardless of project constraints or environmental conditions.

SBS waterproofing membranes represent a proven, reliable solution for protecting buildings and structures from water infiltration. The unique combination of modified bitumen chemistry, reinforcement materials, and flexible installation options makes SBS technology adaptable to virtually any waterproofing challenge. Understanding the composition, properties, applications, and installation requirements of SBS membranes enables informed decision-making that leads to successful waterproofing outcomes.

Whether you’re planning a new construction project, renovating an existing building, or addressing waterproofing failures, SBS membrane systems offer a time-tested approach backed by decades of real-world performance. The investment in quality SBS waterproofing pays dividends through extended service life, reduced maintenance requirements, and the peace of mind that comes from knowing your building is protected by one of the construction industry’s most reliable waterproofing technologies.

For expert guidance on selecting and installing the right SBS waterproofing system for your specific needs, visit Great Ocean Waterproof to explore our comprehensive range of waterproofing solutions and connect with experienced professionals dedicated to protecting your investment.