JY-APP Modified Bitumen Waterproofing Membrane Modified Asphalt Waterproof Membrane

JY-SBS Modified Bitumen Waterproofing Membrane is a standard torch-applied sheet produced by Great Ocean Waterproof in our China factory. This 3mm/4mm thick APP modified bitumen membrane uses polyester or composite reinforcement and is finished with PE film, fine sand, or mineral slate on both sides. As a direct manufacturer, we keep consistent stock of common specifications (1m × 10m rolls) and offer competitive factory price for full-container and LCL orders. Suitable for flat or low-slope roofs, basements, and underground projects across different climate zones. Material meets GB 18242-2008 standard, and test reports are available upon request. For current price and technical data sheet, contact us directly.

Product Introduction

JY-APP Modified Bitumen Waterproofing Membrane is a torch-on rollable sheet manufactured by Great Ocean Waterproof for flat and low-slope roofing, basements, tunnels and foundation waterproofing.

The membrane uses polyester felt or glass fiber felt as reinforcement carrier, coated with random polypropylene (APP) modified bitumen compound that provides higher heat resistance than standard SBS-modified versions. Upper surface is protected with mineral slate, fine sand or PE film; lower surface carries torch-off PE film for easy installation.

Common thickness 3mm / 4mm, standard roll size 1m × 10m, with PY (polyester) and G (glass fiber) base options. This app modified waterproofing bitumen membrane performs reliably in hot climate zones and exposed app roofing systems where summer roof temperatures regularly exceed 80°C.

Material complies with China GB 18242-2008 standard for APP plastomer modified bitumen membranes. Factory test reports (softening point ≥150°C, cold flexibility -5°C to 0°C, tensile strength ≥500 N/50mm) are supplied with every shipment.

Stock available year-round for immediate container or LCL loading from our plant. For current pricing, technical data sheet or sample roll, contact us directly.

| Thickness(mm) | 3.0 / 4.0 / 5.0 | Length(m) | 7.5 / 10 | Width(m) | 1.0 |

| Surface | PE / S / M | Underface | PE / S | ||

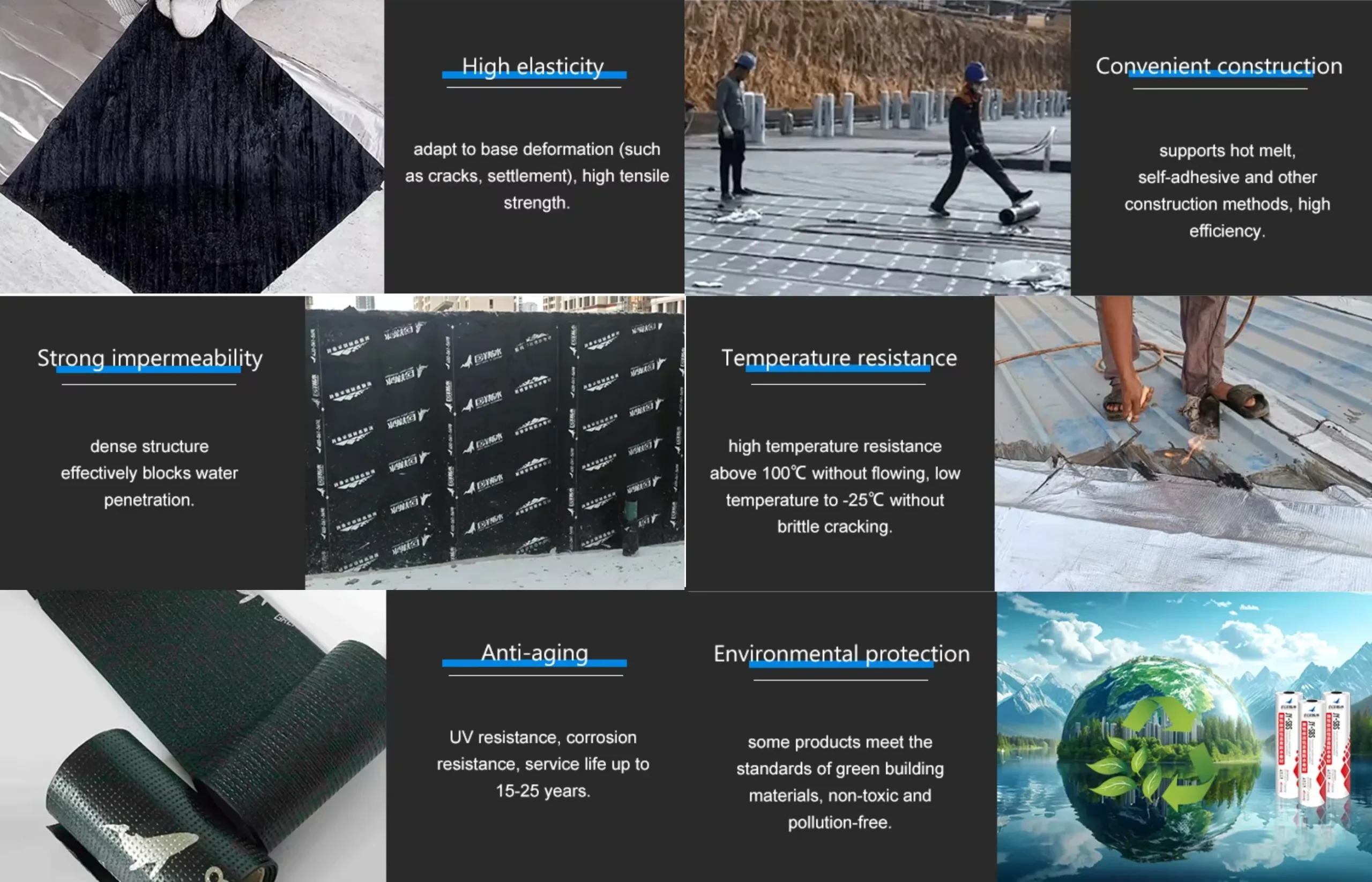

Product Features

- High-temperature flow resistance: APP modifier raises softening point above 130°C (versus ~70°C for plain asphalt), preventing sagging or flow during hot summers – the primary reason contractors choose this app waterproofing membrane in tropical and desert regions.

- No water channeling: Fully sealed torch-applied layers, high tensile strength with polyester or fiberglass carrier, good dimensional stability, and strong resistance to substrate cracking and settlement movement.

- Superior heat performance: While SBS grades suit cooler climates, APP modified bitumen membranes are the standard specification for projects where roof surface temperatures regularly exceed 80–90°C.

- Excellent resistance to UV aging, oxidation, acid rain, alkali, ozone, and most common chemical corrosion when finished with mineral slate or granules.

- Proven durability in exposed app modified bitumen roofing systems: resistant to puncture, tearing, root penetration, and fatigue over long-term thermal cycling.

- Straightforward installation: Torch-on application is fast and familiar to most roofing crews; seams can be reliably heat-welded in one pass.

All rolls are produced in our own plant under GB 18242-2008 quality control. Stock specifications (3 mm & 4 mm, PY & PYG, sand/PE/mineral finish) are ready for immediate container loading. Contact us for current pricing and samples.

APP Implementation Standard GB18243-2008

| No. | Item | Ⅰ | Ⅱ | ||||

|---|---|---|---|---|---|---|---|

| PY | G | PY | G | PYG | |||

| 1 | Soluble matter content / (g/m²) ≥ | 3mm | 2100 | * | |||

| 4mm | 2900 | * | |||||

| 5mm | 3500 | ||||||

| Experimental phenomenon | * | Tire base non combustible | * | Tire base non combustible | * | ||

| 2 | Heat resistance | °C | 110 | 130 | |||

| ≤ mm | 2 | ||||||

| Experimental phenomenon | No flow or dripping | ||||||

| 3 | Low temperature flexibility/°C | -7 | -15 | ||||

| No cracks | |||||||

| 4 | Impermeability for 30 minutes | 0.3MPa | 0.2MPa | 0.3MPa | |||

| 5 | Pulling force | Maximum peak tensile force/(N/50mm) ≥ | 500 | 350 | 800 | 500 | 900 |

| Secondary peak tension/(N/50mm) ≥ | * | * | * | * | 800 | ||

| Experimental phenomenon | There is no cracking or separation of the asphalt coating layer from the tire base in the middle of the test piece | ||||||

| 6 | Elongation rate | Maximum peak elongation/% ≥ | 30 | * | 40 | * | * |

| Elongation at the second peak/% ≥ | * | * | * | * | 15 | ||

| 7 | Oil leakage | Number of sheets ≤ 2 | |||||

Application Range – JY-APP Modified Bitumen Waterproofing Membrane

The JY-APP modified bitumen membrane is widely specified wherever sustained high roof temperatures are expected. Typical uses include:

- Exposed or protected roofing systems on industrial buildings, warehouses, factories, shopping centers, and residential blocks in hot climate zones

- Single-ply or multi-layer waterproofing for flat and low-slope concrete roofs

- Underground waterproofing and damp-proofing of basements, parking garages, tunnels, and foundations in civil and industrial projects

- Lining and waterproofing of indoor swimming pools, fire-water storage tanks, and potable-water reservoirs (non-potable grades available)

- Bridge decks, podiums, and planters when used as part of a complete app modified waterproofing bitumen membrane system

Because of its elevated softening point (>130 °C) and good UV stability when mineral-finished, contractors regularly choose this app modified bitumen compound for projects across the Middle East, North Africa, Southeast Asia, Northern Australia, and southern provinces of China where summer roof temperatures routinely exceed 80–90 °C.

Standard rolls (3 mm & 4 mm, polyester or composite reinforcement, PE/sand/mineral finish) are kept in stock year-round for immediate shipment. Send us your project location and specification – we will confirm the correct grade and quote within 24 hours.

Installation Guidelines

JY-APP membranes are torch-applied (propane gas torch). Cold adhesive or hot-mopped asphalt methods are possible for large areas, but torch-on remains the most common practice.

Substrate Preparation

- Concrete substrate must be clean, dry, structurally sound, and free of dust, oil, or loose particles.

- Apply bitumen primer evenly and allow full drying (usually 4–6 hours).

- For underground works, install additional protection board or drainage layer after the membrane if backfill is required.

Laying Sequence

- Always start from the lowest point and work upward.

- Side laps: minimum 80 mm (roof) or 100 mm (underground); end laps: minimum 150 mm.

- Stagger end laps of adjacent rolls by at least 300 mm.

- Roof slope <3 %: lay parallel to the slope. Slope 3–15 %: lay perpendicular to the slope preferred. Slope >15 % or vertical walls: lay perpendicular and mechanically fix at the top.

Torch Application Steps

- Unroll the membrane 1–2 meters and align properly.

- Re-roll loosely from both ends toward the center.

- Heat the lower PE film evenly with a wide-flame torch until the bitumen surface shows a glossy flow (about 3–5 mm melt layer).

- Unroll while torching, pressing firmly with a roller to expel air and ensure full adhesion.

- Side and end laps must show a continuous 5–10 mm bitumen bead when properly welded.

- Mineral-slate finish rolls: avoid overheating the granules; torch only the overlapping edge.

Special Details

- Upstands / parapets: carry membrane minimum 150–200 mm above finished floor level and protect with metal flashing.

- Penetrations (pipes, drains): use pre-formed collars or double-layer reinforcement.

- Two-layer systems: first layer torch-bonded fully, second layer with staggered joints and partial bonding on mineral surface (if gravel-ballasted).

- Rock wool or XPS insulation boards: membrane can be directly torched onto compatible boards.

Long & Short Edge Overlap Rules

- Long edge: ≥80 mm on roofs, ≥100 mm underground.

- Short edge: ≥150 mm everywhere.

- When two-layer applications: first layer fully bonded, second layer offset by half roll width.

Safety & Quality Notes

- Torch flame should never directly touch the polyester carrier – only the PE film.

- Final inspection: check all seams for continuous bitumen bleed-out.

- After completion, protect the finished membrane from mechanical damage until protection layer or surfacing is applied.

All standard 3 mm and 4 mm rolls (PY, PYG, sand/mineral/PE finish) are produced in our plant under strict GB 18242-2008 control. Detailed installation manual and video links are sent with every order. For site-specific advice or contractor training, contact us directly.

JY-APP vs JY-SBS Modified Bitumen Waterproofing Membrane

| Item | JY-APP (Atactic Polypropylene Modified) | JY-SBS (Styrene-Butadiene-Styrene Modified) |

|---|---|---|

| Main Modifier | Random polypropylene (APP) | SBS elastomer |

| Heat Resistance | Better – softening point ≥150°C | Standard – softening point 110–120°C |

| High Temperature Flow Resistance | Excellent – suitable for hot climates (regular roof temperature >80°C) | Moderate – can soften in extreme summer heat |

| Low Temperature Flexibility | -5°C to 0°C (PY type) / 0°C to +5°C (G type) | Better – usually -20°C to -25°C |

| Cold Climate Performance | Acceptable in mild winters | Preferred where temperature drops below 0°C for long periods |

| UV & Exposed Roofing | Standard choice for exposed app roofing systems with mineral slate finish | Usually requires additional protection layer or gravel |

| Typical Applications | Tropical / subtropical zones, Middle East, North Africa, Southern China, exposed roofs | Temperate zones, underground structures, Europe, Northern China, concealed roofs |

| Elongation at Break | 30–40% | Higher – 800–1500% |

| Installation Method | Torch-applied (same as SBS) | Torch-applied or hot-mopped |

| Standard Executed | GB 18242-2008 (APP type) | GB 18243-2008 (SBS type) |

| Common Thickness | 3mm, 4mm | 3mm, 4mm |

| Factory Price Range (2025) | Almost the same – APP usually 2–5% higher due to raw material cost | Standard reference price |

- Choose JY-APP modified bitumen membrane if your project is in hot regions (Brazil Northeast, Middle East, Southeast Asia, Australia) or you need long-term exposed roof without extra protection layer.

- Choose JY-SBS if the building is in colder areas or the membrane will be covered (ballast, soil, insulation board) and you want maximum crack-bridging ability.

Both products are manufactured in the same Great Ocean Waterproof plant with identical polyester/glass-fiber carriers and quality control. Stock of both types is kept year-round. Send us your project location and whether the roof is exposed – we will recommend the correct type and quote accordingly within 24 hours.

Customer Reviews

Ahmed Al-Mansoori – Dubai, UAE (August 2025) ★★★★☆ “Used 4 mm grey mineral APP on a 9,000 m² warehouse roof. Surface temperature here reaches 85–90 °C in summer. After 14 months including two full summers, no blistering, no flow marks of flowing, seams still perfect. Delivery took 22 days to Jebel Ali, packing was good, only 3 rolls had small edge damage. Price was about 12 % lower than Italian brand we used before.”

Carlos Ramírez – Lima, Peru (June 2025) ★★★★☆ “Bought one 20 ft container of 3 mm sand-finish for residential flat roofs. Material arrived in 38 days to Callao. The rolls are uniform thickness and the torch film melts evenly, crews said easier to install than the local brand we normally buy. So far no callbacks from the 11 buildings we finished in March.”

Joseph Okafor – Lagos, Nigeria (October 2024) ★★★★☆ “Ordered 4 mm polyester with green slate for a shopping mall in Ikeja. Clearing in Lagos took longer than shipping, but goods arrived without water damage. We have heavy rain here; after one rainy season no leaks reported. The mineral granules stay attached well, unlike some cheaper membranes we tried before.”

Ricardo Santos – São Paulo, Brazil (April 2025) ★★★★☆ “Took 650 rolls of 4 mm PE-finish for underground parking garage (two-layer system). The APP compound is stiffer than SBS, but our team prefers it because it doesn’t stick to itself when is hot in the container. Adhesion to concrete after priming was strong. Test samples passed pull-off test >1.5 N/mm².”

Tan Wei Jie – Jakarta, Indonesia (January 2025) ★★★★☆ “Used 3 mm PY sand surface as cap sheet over XPS insulation on factory roof. Roof gets very hot and humid. Nine months in, colour still uniform, no cracking at overlaps. Factory gave us loading photos and test report before shipment – everything matched when goods arrived.”

Frequently Asked Questions – JY-APP Modified Bitumen Waterproofing Membrane

Q1: What is the minimum order quantity (MOQ)? A: One 20ft container (usually 550–650 rolls depending on thickness and surface). LCL orders are accepted but freight cost will be higher.

Q2: What is the current factory price (December 2025)? A: FOB Qingdao price range: – 3 mm polyester sand/PE finish: USD 1.15–1.30 per m² – 4 mm polyester mineral slate finish: USD 1.75–1.95 per m² Exact price depends on quantity, surface color, and raw material index. Send us your specification for a quotation valid 7 days.

Q3: How many rolls can be loaded in a container? A: – 20ft GP: 550–650 rolls (palletized or vertical) – 40ft HQ: 1100–1300 rolls We provide free loading photos before shipment.

Q4: What is the lead time? A: Stock specifications ship within 7–10 days after deposit. Custom mineral color or private label: 15–20 days.

Q5: What certificates do you provide? A: Every shipment comes with – Factory test report according to GB 18242-2008 – SGS/Intertek third-party test report (optional, extra cost) – Certificate of Origin & Fumigation certificate if required

Q6: What is the warranty period? A: 10-year material warranty for polyester base, 12-year for mineral slate finish when installed according to our guidelines.

Q7: Can you print our own brand/logo on the rolls? A: Yes, free private label printing (your logo on PE film and carton label) for orders ≥5 containers. Smaller orders: USD 150–200 printing fee.

Q8: Can we get free samples? A: Yes – one A4 size or half-meter sample piece is free (courier fee collect). Full 1×10 m sample roll cost will be deducted from first container order.

Q9: How long does it take to ship to Middle East / Africa / South America? A: – Dubai / Jeddah: 18–25 days – Lagos / Mombasa: 35–45 days – Santos Brazil / Buenos Aires: 35–40 days

Q10: What is the difference between APP and SBS membrane? A: APP is designed for hot climates (softening point >150 °C), ideal for exposed roofing in summer temperatures >80 °C. SBS offers better flexibility at low temperatures (down to -25 °C) and is normally used in colder regions or underground works.

Q11: Do you supply bitumen primer and accessories? A: Yes – solvent-based and water-based bitumen primer, aluminium flashing tape, and protection board are available from the same factory.

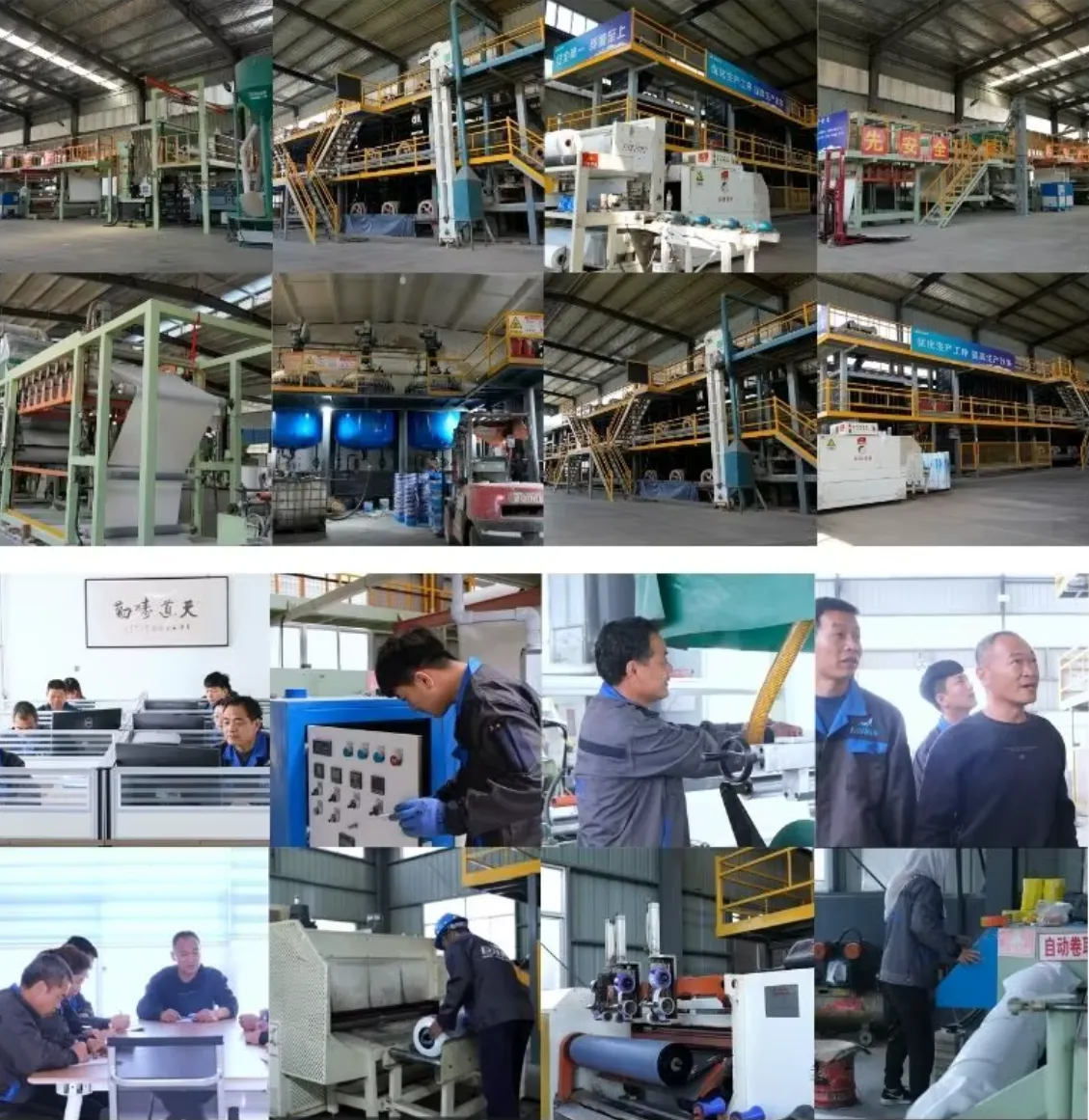

About the Manufacturer – Great Ocean Waterproof Technology Co., Ltd.

Great Ocean Waterproof Technology Co., Ltd. (formerly Weifang Great Ocean New Waterproof Material Co., Ltd.) was established in 1999 and is located in Taitou Town, Shouguang City – the largest waterproof material production base in China.

Factory covers 26,000 m² and operates multiple modern production lines for waterproof membranes, sheets and coatings, including the complete JY-951 Waterborne Polyurethane Waterproof Coating series. We produce over 40 product categories ranging from modified bitumen and TPO/PVC membranes to polymer cement (JS), single-component and dual-component polyurethane coatings, non-curing rubber asphalt coatings and root-resistant membranes.

The plant is equipped with automatic coating lines, high-speed mixers, laboratory reactors and full quality-control testing facilities. All products, including JY-951 water-based polyurethane coating, are manufactured under ISO 9001 quality management system and have passed national CRCC railway certification, Ministry of Agriculture quality compliance and Shandong Province industrial product filing.

Our materials are widely used across more than 20 provinces in China and exported to the Middle East, Southeast Asia, Africa, South America and CIS countries. We keep large stock of standard specifications and offer stable factory-direct pricing year-round.

Great Ocean Waterproof maintains the principle of “integrity, practicality and innovation” and focuses on delivering reliable, cost-effective waterproofing solutions with professional pre- and after-sales support.

For factory visit, third-party inspection arrangement or latest price list of JY-951 Waterborne Polyurethane Waterproof Coating, please contact us directly – we reply within 12 hours.

![JY-ZSE High Elongation Self-Adhesive Waterproofing Membrane [e]](https://great-ocean-waterproof.com/wp-content/uploads/2025/12/JY-ZSE-High-Elongation-Self-Adhesive-Waterproofing-Membrane-e2_1-300x300.webp)

![JY-ZSH High Strength Self-Adhesive Waterproofing Membrane [H]](https://great-ocean-waterproof.com/wp-content/uploads/2025/12/JY-ZSH-High-Strength-Self-Adhesive-Waterproofing-Membrane-H2_1-300x300.webp)