JY-SPU Single Componacent Polyurethane Waterproof Coating

JY-SPU is a reactive moisture-curing polymer waterproof coating. It is formulated with isocyanate and polyether as the primary raw materials, blended with various latent curing agents, plasticizers, and other additives, and produced through specialized processes such as high-temperature dehydration and polymerization. When applied to a waterproof substrate, the -NCO end groups in the polyurethane prepolymer react with moisture in the air, forming a tough, flexible, and seamless rubber waterproof membrane on the substrate surface. This product offers the advantages of on-site immediate use, easy application, excellent elasticity, and strong adhesion, making it an ideal choice for reliable waterproof protection.

Product Introduction

|

|

|

|

Main Product Information

| Application Range | Details |

|---|---|

|

Building waterproofing applications |

1.6 kg/m² – 1.8 kg/m² (per mm thickness) |

| Color |

Black / Red |

|

Density |

1.3–1.4 kg/L |

|

Pot Life |

4H |

|

Physical State |

Liqui |

|

Packaging Specification |

20 kg/bucke |

Performance Characteristics

- Single-component moisture-curing film formation: Chemically reacts with moisture in the air to form a flexible, rubber-like waterproof membrane.

- Easy application: Ready-to-use, simple construction process. Largely unaffected by moisture content in the substrate; can be applied on relatively damp substrates or in environments with high relative humidity.

- Dense coating: Free of pinholes and bubbles. Single-layer coating thickness can reach 1–3 mm.

- Excellent mechanical and temperature resistance properties: High tensile strength, large elongation, good rubber elasticity and resilience. Outstanding resistance to both high and low temperatures, with strong adaptability to substrate contraction and deformation cracking.

- Strong adhesion: No primer required on various qualified substrates.

- Excellent resistance: Resistant to water erosion, chemical corrosion, and mold growth.

- Environmentally friendly with good low-temperature flexibility: Contains no toxic solvents such as benzene, toluene, or xylene, and is free of coal tar components. Also exhibits excellent low-temperature bending performance.

- Customizable colors: Adjustable colors available to meet customers’ individual requirements for surface color.

Main Technical Performance Indicators

Implemented Standard: GB/T 19250-2013

| Serial No. | Item | Technical Index (Type I) | Technical Index (Type II) | Technical Index (Third Category) | |

|---|---|---|---|---|---|

| 1 | Solid Content % ≥ | 85 | |||

| 2 | Drying Time | Surface Drying Time h ≤ | 12 | ||

| Actual Drying Time h ≤ | 24 | ||||

| 3 | Tensile Strength MPa ≥ | 2.0 | 6.0 | 12.0 | |

| 4 | Elongation at Break % ≥ | 500 | 450 | 150 | |

| 5 | Water Impermeability (0.3MPa for 30 minutes) | Waterproof | |||

| 6 | Low-Temperature Flexibility °C ≤ | -35 | |||

| 7 | Adhesion Strength MPa ≥ | 1.0 | |||

| Flatness | No obvious indentation after 20 minutes | ||||

| a. This performance is not applicable to single-component and spray-applied products. | |||||

Application Scope

|

|

|

|

|

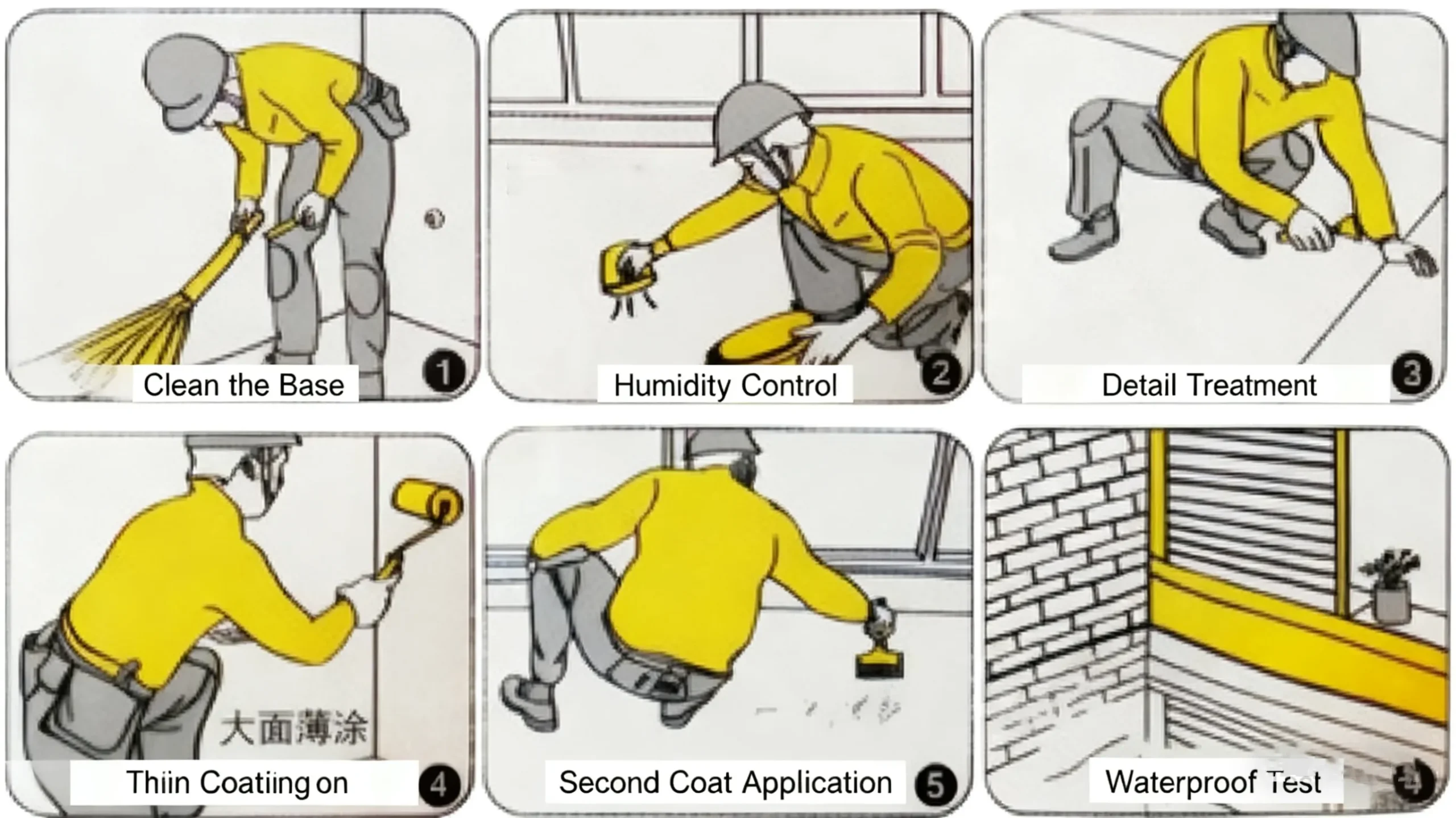

Construction Process

1. Pre-Construction Prep

- Stir the JY-SPU coating (within shelf life) evenly for 3–5 minutes; no dilution needed. Reference Dosage: 1.3–1.5 kg/m² for 1mm dry film.

- Prepare tools: Rubber/plastic scrapers (large areas), brushes (corners/pipes), thickness gauge, and safety gear.

- Environmental requirement: Construct at 5–35℃; avoid rain/wind (>5 m/s); base moisture ≤15%.

2. Base Layer Preparation

- Ensure the base (concrete/mortar) is solid, flat, and debris-free. Wipe oil with ethanol; patch cracks (>0.3mm with mortar).

- Corner Treatment: Internal corners (radius >50mm) and external corners (radius >10mm) must be arc-shaped to prevent cracking.

- For pipes/joints: First apply a 0.5mm "reinforcement coat" with a brush.

3. Coating Application

- Use scrapers for even coating; total thickness 1.5–2.0mm via 3–4 perpendicular coats (apply next only after previous cure).

- Underground floors: Embed a reinforcing membrane between coats.

|

Scene |

Thickness Requirement |

|

Underground Engineering |

1.2–2.0mm (typically 1.5mm) |

|

Bathrooms/Toilets |

≥1.5mm |

|

Exposed Roofs (Multi-coat) |

Each coat ≥1.2mm |

|

Exposed Roofs (Single-coat, Class Ⅲ) |

≥2mm |

|

Roofs with Membrane |

≥1.0mm (under); ≥0.5mm (above) |

4. Finishing & Curing

- After the final coat (pre-cure), sprinkle clean sand grains to boost decor layer adhesion.

- Cure fully for 24–48 hours (20–25℃, 50–70% humidity); avoid contact during curing.

5. Inspection & Protection

- Visual: No pinholes/bubbles; Thickness: Meet scene standards; Adhesion: No peeling (grid test); Waterproof: 24h immersion (no seepage).

- Add an isolation protective layer (per design) to avoid UV/mechanical damage. Repairs need 50mm overlap with original film.

Customer Reviews

We value feedback from our users around the world. Here are some recent reviews from customers who have used JY-SPU in various projects:

- John D., United States (Roof Repair Project): "I applied JY-SPU to my flat roof in Florida after some leaks from heavy rains. It went on smoothly with a roller and dried without issues. After a few months, it has held up well against the sun and storms. No more water problems so far."

- Maria S., Spain (Balcony Waterproofing): "Used this on my apartment balcony in Madrid, which had cracks letting water in. The single-component aspect made it easy to handle without mixing. It adhered nicely to the tiles and has prevented seepage during the rainy season. Satisfied with the results after six months."

- Ahmed K., United Arab Emirates (Basement Sealing): "In Dubai's humid climate, I needed something reliable for my villa's basement walls. JY-SPU provided good coverage with two coats and has kept the area dry. It's flexible enough to handle minor settling without cracking. Application was straightforward, though I recommend good ventilation."

- Lisa T., Australia (Pool Deck Coating): "Applied JY-SPU around my swimming pool deck in Sydney to stop water pooling and slipping hazards. It bonded well to the concrete and has maintained its integrity through hot summers and wet winters. Easy to clean and no peeling observed after a year."

- Hans M., Germany (Industrial Floor Protection): "For a warehouse floor in Berlin exposed to occasional spills, this coating worked effectively. It cured evenly and has resisted wear from foot traffic. Not the cheapest option, but it performs as described without major drawbacks."

These reviews reflect real user experiences and highlight the product's versatility across different climates and applications.

Case Studies

To demonstrate JY-SPU's practical use, here are a few documented examples from completed projects:

- Residential Roof in California, USA (2024): A 500 m² roof on a single-family home was treated with JY-SPU after repeated leaks. Two coats were applied over prepared concrete. Post-application monitoring over 12 months showed no water penetration, even during heavy El Niño rains. The flexibility helped with thermal expansion, reducing maintenance needs.

- Commercial Building Basement in Shanghai, China (2023): In a high-rise office basement prone to groundwater seepage, JY-SPU was used on 1,200 m² of walls and floors. The coating's quick cure time allowed the project to finish ahead of schedule. Inspections after 18 months confirmed dry conditions, with no mold growth reported.

- Public Infrastructure Bridge Deck in the UK (2024): A pedestrian bridge in London required waterproofing on its 300 m² deck to prevent corrosion. JY-SPU was sprayed on, forming a seamless layer. It has withstood urban pollution and weather cycles, with routine checks showing sustained adhesion and no surface degradation.

Frequently Asked Questions (FAQ)

Here are answers to some common questions from customers about JY-SPU Single Component Polyurethane Waterproof Coating:

- What surfaces is JY-SPU suitable for? JY-SPU can be applied to concrete, metal, wood, and tiled surfaces. It adheres well to clean, dry substrates but may require testing on porous or unusual materials to ensure compatibility.

- How many coats are typically needed? One to two coats are usually sufficient for most applications, with each coat at 1-1.5 kg/m². Additional coats may be needed for high-exposure areas or very porous surfaces to achieve full waterproofing.

- What is the drying and curing time? Touch-dry time is about 4-6 hours per coat under normal conditions (20-25°C, 50-60% humidity). Full curing takes up to 7 days, during which the area should be protected from water and heavy traffic.

- Is JY-SPU safe for indoor use? Yes, it has low VOC content, making it suitable for indoor applications with proper ventilation during application. Wear protective gear like gloves and masks, and ensure good airflow to minimize fumes.

- How long does the waterproofing last? Under typical conditions, JY-SPU provides effective waterproofing for 5-10 years, depending on environmental factors like UV exposure, temperature fluctuations, and mechanical wear. Regular inspections are recommended.

- Can JY-SPU be applied in wet or cold weather? It should not be applied on wet surfaces or in temperatures below 5°C. Ideal application is in dry conditions between 10-35°C. Rain within 24 hours after application may affect curing.

- What tools are needed for application? A brush, roller, or spray equipment works well. No special mixing tools are required since it's single-component. Clean tools with solvent immediately after use.

- Is a primer necessary? In most cases, no primer is needed on clean concrete or metal. However, for highly absorbent or dusty surfaces, a compatible primer can improve adhesion—consult the technical data sheet for specifics.

- How do I store unused product? Store in a cool, dry place away from direct sunlight, with the container tightly sealed. Shelf life is 12 months unopened; once opened, use within a few weeks to avoid skinning.

About Geart Ocean Waterproof

Great Ocean Technology Co., Ltd. (formerly Weifang Juyang New Waterproof Materials Co., Ltd.) is located in Taitou Town, Shouguang City—the largest waterproof material base in China. Founded in 1999, we are a high-tech professional waterproof enterprise integrating scientific research, production, and sales in the waterproof industry. Our factory covers an area of 26,000 square meters. Through years of development and innovation, we have multiple advanced production lines for roll materials, sheets, and coatings in China. Our main products cover dozens of categories, such as polyethylene polypropylene (polyester) polymer waterproof membranes, PVC waterproof membranes, TPO waterproof membranes, CPE waterproof membranes for high-speed railways, polymer self-adhesive waterproof membranes, non-asphalt-based reactive pre-laid polymer self-adhesive waterproof membranes, drainage protection boards, modified bitumen waterproof membranes, root-penetration resistant waterproof membranes, single-component polyurethane waterproof coatings, two-component polyurethane waterproof coatings, JS composite waterproof coatings, cement-based capillary crystallization waterproof coatings, spray-applied quick-drying rubber bitumen waterproof coatings, and more.

We possess strong technical capabilities, equipped with a professional team of technicians, advanced equipment, and comprehensive testing instruments to ensure stable and reliable product quality. Our products have passed certifications from national authoritative testing institutions. We have been awarded the "Compliant with Integrated Quality Management System" title by the Ministry of Agriculture of China and have obtained quality assurance system certification. Furthermore, we have obtained multiple certifications, including the "Nationally Recognized Qualified Product" certificate from the China Quality Inspection Association, the "Shandong Province Industrial Building Product Registration Certificate," and the "Industrial Product Production License." Notably, we offer customized size services for waterproofing products to meet the specific needs of different construction projects. For any customization needs or business inquiries, please feel free to contact us.

|

|

|

|