JY-ZSH High Strength Self-Adhesive Waterproofing Membrane [H]

The JY-ZSH [H] is a high-strength self-adhesive modified bituminous waterproofing membrane designed for non-exposed applications. It features a robust modified asphalt adhesive layer covered with a durable polymer film on the top surface and peelable silicon-coated release liners on both sides for easy handling and installation.

Available in 1.5 mm and 2.0 mm thicknesses, with standard roll dimensions of 1 m × 20 m, it provides reliable cold-applied waterproofing through direct adhesion to prepared concrete or masonry substrates. The flame-free peel-and-stick method makes it suitable for basements, foundations, tunnels, water tanks, and protected roof systems where consistent bonding and resistance to water ingress are required.

Product Introduction

JY-ZSH High Strength Self-Adhesive Waterproofing Membrane [H] consists of a self-adhesive modified asphalt layer that serves as the sealing component, paired with a high-strength polymer film or peelable silicon-coated isolation film on the upper side and a similar peelable silicon-coated film on the lower side. This setup forms a flexible, rollable sheet material suitable for waterproofing tasks. It comes in thicknesses of 1.5 mm or 2.0 mm, with rolls measuring 20 meters in length and 1.0 meter in width. The upper surface is labeled as PF, and the lower includes a separator layer for handling during installation. As a self adhesive waterproofing membrane for roof, it bonds directly to substrates without needing extra primers in standard conditions, based on typical product data from manufacturers like Joaboa Tech.

![JY-ZSH High Strength Self-Adhesive Waterproofing Membrane [H]](https://great-ocean-waterproof.com/wp-content/uploads/2025/12/JY-ZSH-High-Strength-Self-Adhesive-Waterproofing-Membrane-H_1.webp)

Performance Index

| No. | Item | Indicator | |

|---|---|---|---|

| H | |||

| 1 | Soluble content/(g/m²) | - | |

| 2 | Tensile property | Tearing force /(N/50 mm) ≥ | 300 |

| Elongation at maximum tensile ≥ | 50 | ||

| Phenomenon during stretching | The adhesive layer is not separated from polymer film or tire base | ||

| 3 | Tearing force/N ≥ | 20 | |

| 4 | Heat resistance (70℃, 2h) | No flow, dripping, slip ≤ 2mm | |

| 5 | Low temperature flexibility(-20℃) | No cracks | |

| 6 | Impermeability | waterproof | |

| 7 | Roll and roll peel strength/(N/mm) | No processing | 1.0 |

| Immersion treatment | 0.8 | ||

| Heat treatment | 0.8 | ||

| 8 | Oil leakage/number of sheets ≤ | 2 | |

| 9 | Holding viscosity/min ≥ | 30 | |

| 10 | Peel strength with cement mortar/(N/mm) | No processing ≥ | 1.5 |

| Heat treatment ≥ | 1.0 | ||

| 11 | Peel strength after immersion in cement mortar (N/mm) ≥ | 1.5 | |

| 12 | Thermal ageing (70℃, 168h) | Tensile retention rate/% | 90 |

| Elongation retention rate/% | 80 | ||

| Low temperature flexibility (-18℃) | No cracks | ||

| 13 | Dimensional change/ % | ±1.0 | |

| 14 | Thermal stability | No bulging, smooth, with maximum curling of polymer film or tire base edge not exceeding 1/4 of the side length | |

Key Features

- Upper surfacing uses high-strength polymer film (PF) that provides reliable dimensional stability, strong UV resistance, and good performance at low temperatures.

- The combination of physical adhesion, tenon effect, and chemical cross-linking reaction allows the membrane to form a continuous, integral waterproof layer with the substrate, delivering long-term bond strength and resistance to environmental stress.

- When installed using the paving method on roofs, it requires no special preparation of uneven substrates, no primer coat, and no cement mortar or paste for bonding — the self-adhesive layer directly adheres to the base with high resistance to puncture and damage.

- Offers effective waterproofing performance that prevents both liquid water and water vapor penetration into the structure.

- The modified asphalt compound exhibits high creep resistance and excellent adaptability to substrate movement and deformation, making it suitable for a wide range of roof waterproofing membrane applications and different construction conditions.

Applications

This self-adhesive modified asphalt membrane is designed primarily for non-exposed applications, making it appropriate for underground structures and indoor engineering projects.

It performs well in complex waterproofing scenarios, including open-cut subways, tunnels, water tanks, and water channels. The cold-applied installation process — requiring no open flames — provides clear advantages in confined spaces or areas where torch-on methods are prohibited due to safety regulations.

Common uses include:

- Below-grade waterproofing membrane for walls on foundations and basements, where it adheres directly to concrete surfaces.

- As a waterproofing membrane for concrete in retaining structures, parking garages, and planter boxes.

- Horizontal or vertical applications on non-exposed roofs under ballast, insulation, or green roof systems (as an alternative to traditional EPDM roofing self adhesive waterproofing membrane in certain non-UV-exposed setups).

- Self adhesive foundation waterproofing membrane systems for new construction or retrofit projects requiring reliable protection against groundwater ingress.

Its ability to bond to prepared substrates without heat makes it particularly practical for sensitive environments where hot-work permits are restricted.

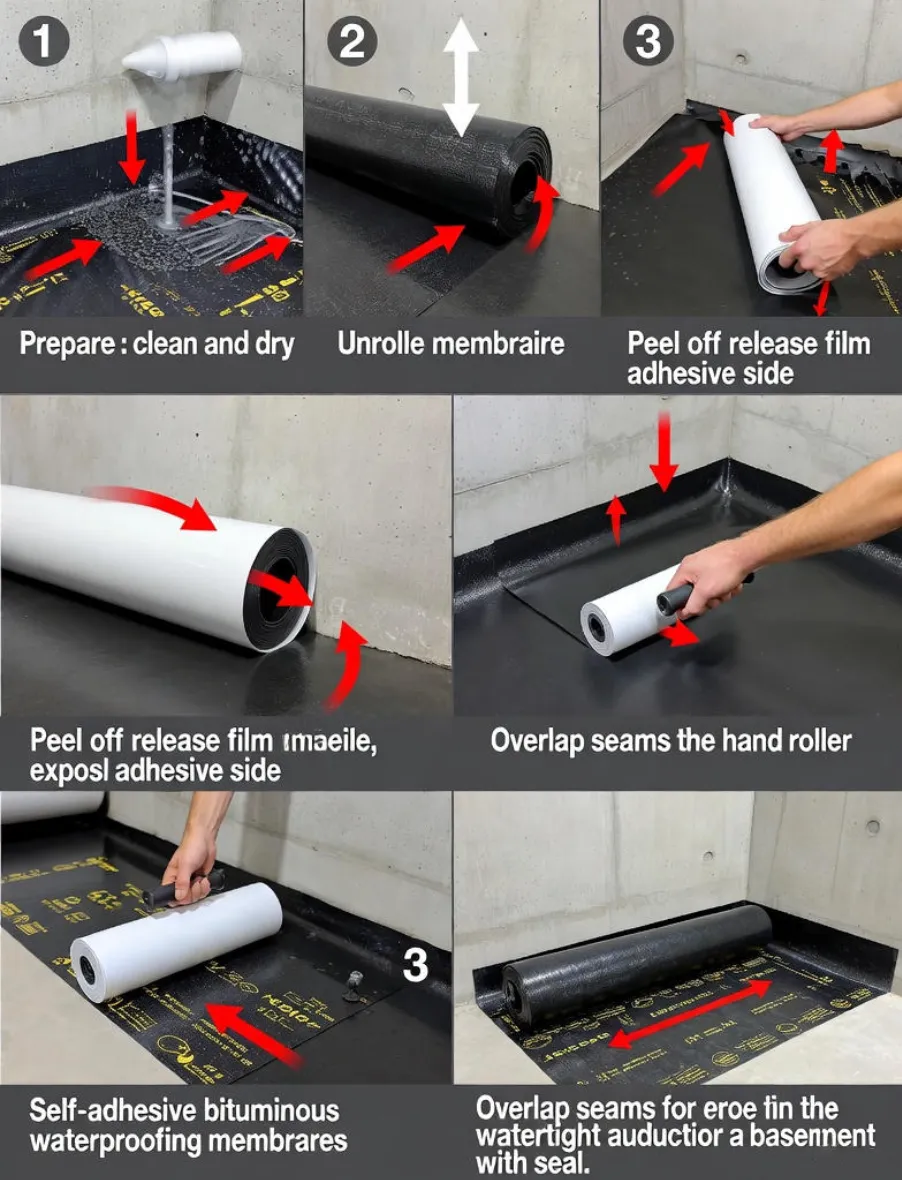

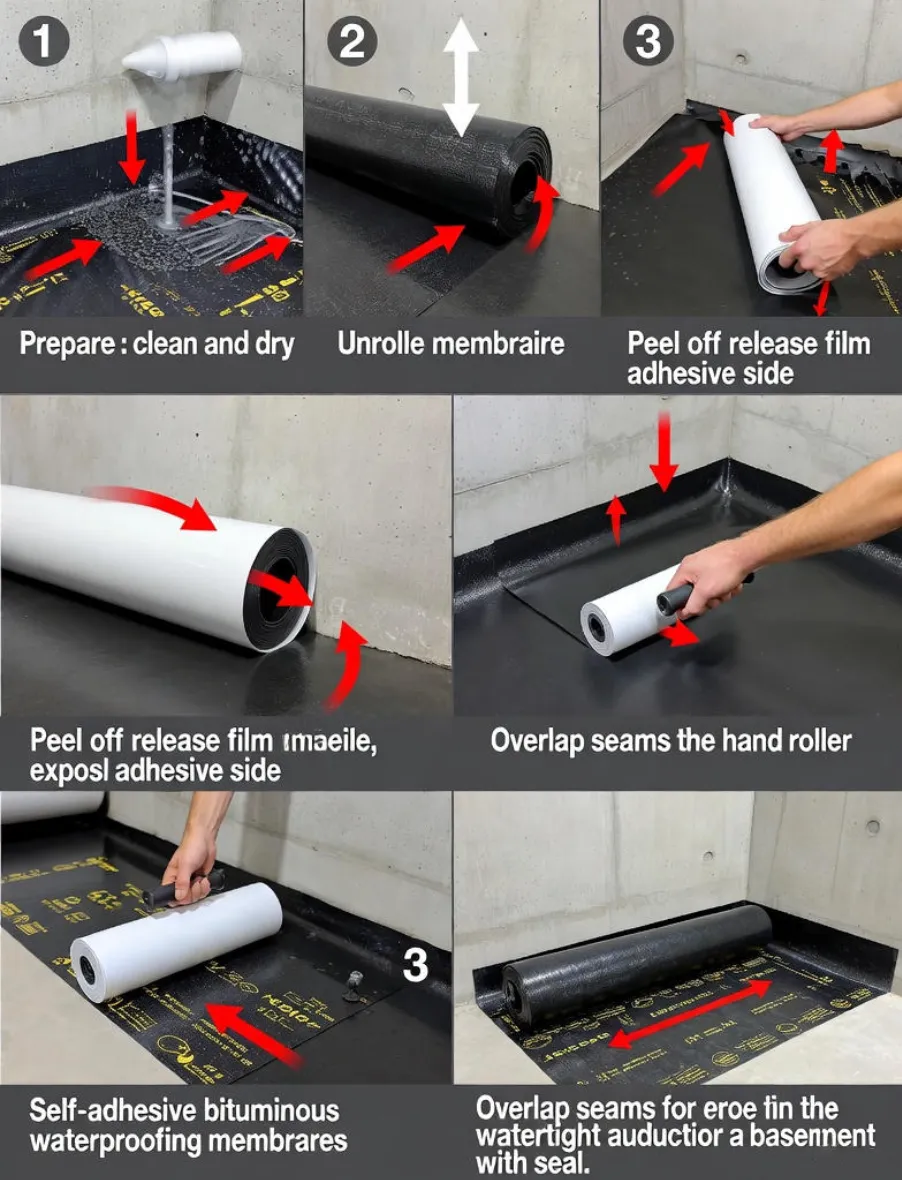

Installation Methods

The JY-ZSH is a self adhesive bituminous waterproofing membrane applied using a cold, peel-and-stick process that requires no open flames or hot asphalt, making it suitable for non-exposed areas and sites with fire restrictions.

Standard installation steps include:

- Prepare the substrate by ensuring it is clean, dry, stable, and free of dust, oil, loose particles, or protrusions. Minor unevenness is typically accommodated without extensive leveling.

- Apply a bituminous primer if recommended for the specific substrate conditions to improve adhesion (many installations proceed without primer on suitable concrete surfaces).

- Unroll the membrane, align it properly, and gradually peel away the silicon-coated release film from the underside while pressing the adhesive side firmly onto the substrate.

- Use a heavy roller to press the entire surface, expelling air pockets and ensuring full contact for strong bonding.

- Overlap adjacent sheets by the specified amount (usually 75-100 mm on side laps and 150 mm on end laps), removing the release strip at overlaps and rolling seams to create a continuous seal.

- Treat details around penetrations, corners, and transitions with additional membrane pieces or compatible sealants.

This method works well for underground structures, tunnels, and as a basement waterproofing membrane, where direct adhesion to concrete provides reliable protection against groundwater. Always follow site-specific conditions and local guidelines for best results.

Customer Reviews

John M., Contractor, USA ★★★★☆ "We used this membrane for a basement retrofit project. The self-adhesive backing stuck well to the concrete without needing a primer in most areas, and the overlaps sealed reliably after rolling. It's been six months with no signs of moisture ingress so far. Solid option when looking for self adhesive waterproofing membrane for sale."

Maria S., Builder, Canada ★★★★★ "Applied it on foundation walls in a cold climate. The material remained flexible during installation at around 5°C, and adhesion held up through the winter. It adapts to minor substrate movement better than the self adhesive hdpe waterproofing membrane we've tried before. No issues after one full season."

Ahmed K., Project Manager, UAE ★★★★☆ "Good for underground water tank lining where torching isn't allowed. The peel-and-stick method sped up installation in a confined space. Bond strength seems consistent, and it handles the heat here without softening noticeably. Prefer it over tpo roofing self adhesive waterproofing membrane for non-exposed applications like this."

Li Wei, Engineer, China ★★★★☆ "Used on a tunnel section. The 2mm thickness provided decent puncture resistance during backfill, and the self-adhesive layer formed a continuous barrier without extra sealants at seams. Performs as expected in damp conditions."

Project Case Studies

Case 1: Basement Foundation Waterproofing – Residential Project, North America In a new single-family home construction located in an area with high groundwater levels, the JY-ZSH membrane (1.5 mm thickness) was selected for exterior vertical application on poured concrete foundation walls. The substrate was cleaned and primed only in spots with surface inconsistencies. Crews unrolled and applied the sheets directly, achieving good adhesion without heat. Overlaps were rolled thoroughly to ensure seam integrity. After backfilling with soil and gravel, the system has shown no signs of water intrusion or delamination over two years of monitoring, providing reliable below-grade protection.

Case 2: Underground Tunnel Lining – Infrastructure Project, Asia For a municipal utility tunnel in an urban setting, the 2.0 mm version was used to line concrete segments where open-flame methods were strictly prohibited for safety reasons. Installation involved peeling the release film and pressing the membrane onto the prepared surface in a confined environment. The material's flexibility allowed it to conform to curved sections, and the self-adhesive overlaps formed watertight joints without additional mastics. Post-backfill inspections confirmed puncture resistance and continuous bonding, maintaining a dry interior since project handover.

Case 3: Concrete Water Tank – Municipal Water Storage Facility During the renovation of an existing concrete potable water reservoir, the membrane was applied to interior walls and floor to prevent leakage. The cold-applied peel-and-stick process minimized downtime and avoided risks associated with hot works near water infrastructure. Sheets were cut to fit around outlets and inlets, with careful rolling at details. The adhered layer has held up well under constant water exposure, passing multiple pressure tests and visual checks with no evidence of peeling or moisture migration.

Case 4: Non-Exposed Flat Roof – Commercial Building Retrofit, Europe On a low-slope concrete deck of an industrial warehouse, the JY-ZSH served as the primary waterproofing layer in a protected membrane roof assembly under insulation boards and gravel ballast. Unlike exposed systems such as pvc roofing self adhesive waterproofing membrane or tpo variants, this bituminous option offered a cheapest self adhesive waterproofing membrane solution for non-UV applications while accommodating deck movement. Installation handled minor surface irregularities effectively, and the fully adhered system has prevented leaks through several cycles of rain, snow, and temperature fluctuations. Note that for wet areas like bathrooms, a specialized waterproofing membrane for shower would be more appropriate.

|  |

|  |

About Our Factory

Shandong Great Ocean Waterproof Technology Co., Ltd. (formerly Weifang Juyang New Waterproof Materials Co., Ltd.) is located in Taitou Town, Shouguang City—the heart of China's largest waterproof materials production base. Established in 1999, we are a high-tech enterprise integrating research, production, and sales in the waterproofing industry.

Our facility covers 26,000 square meters and features multiple advanced production lines for membranes, sheets, and coatings. The product range includes polyethylene-propylene (polyester) polymer waterproof membranes, pvc membrane waterproofing, TPO waterproof membranes, specialized CPE membranes for high-speed rail, various self-adhesive polymer membranes, non-asphalt reactive pre-laid membranes, cross-laminated high-strength membranes, drainage boards, SBS/APP modified bitumen membranes, root-resistant puncture membranes, single- and dual-component polyurethane waterproof coating, JS polymer cement coatings, water-based polyurethane options, K11 Waterproof Coating (cementitious crystalline type), spray-applied rubber asphalt coatings, non-curing rubber asphalt coatings, and related accessories such as tapes and glues.

We maintain strong technical capabilities with experienced professionals, modern equipment, and comprehensive testing instruments to ensure consistent product quality. Our operations have earned certifications from national authorities, including full quality management compliance, ISO quality system certification, and product licenses.

Products are supplied across more than 20 provinces in China and exported to several international markets, with a focus on reliable performance for applications like roof waterproof coating. Operating under principles of integrity, practicality, and innovation, we aim to build long-term partnerships through competitive pricing and dedicated service.

Product Introduction

JY-ZSH High Strength Self-Adhesive Waterproofing Membrane [H] consists of a self-adhesive modified asphalt layer that serves as the sealing component, paired with a high-strength polymer film or peelable silicon-coated isolation film on the upper side and a similar peelable silicon-coated film on the lower side. This setup forms a flexible, rollable sheet material suitable for waterproofing tasks. It comes in thicknesses of 1.5 mm or 2.0 mm, with rolls measuring 20 meters in length and 1.0 meter in width. The upper surface is labeled as PF, and the lower includes a separator layer for handling during installation. As a self adhesive waterproofing membrane for roof, it bonds directly to substrates without needing extra primers in standard conditions, based on typical product data from manufacturers like Joaboa Tech.

![JY-ZSH High Strength Self-Adhesive Waterproofing Membrane [H]](https://great-ocean-waterproof.com/wp-content/uploads/2025/12/JY-ZSH-High-Strength-Self-Adhesive-Waterproofing-Membrane-H_1.webp)

Performance Index

| No. | Item | Indicator | |

|---|---|---|---|

| H | |||

| 1 | Soluble content/(g/m²) | - | |

| 2 | Tensile property | Tearing force /(N/50 mm) ≥ | 300 |

| Elongation at maximum tensile ≥ | 50 | ||

| Phenomenon during stretching | The adhesive layer is not separated from polymer film or tire base | ||

| 3 | Tearing force/N ≥ | 20 | |

| 4 | Heat resistance (70℃, 2h) | No flow, dripping, slip ≤ 2mm | |

| 5 | Low temperature flexibility(-20℃) | No cracks | |

| 6 | Impermeability | waterproof | |

| 7 | Roll and roll peel strength/(N/mm) | No processing | 1.0 |

| Immersion treatment | 0.8 | ||

| Heat treatment | 0.8 | ||

| 8 | Oil leakage/number of sheets ≤ | 2 | |

| 9 | Holding viscosity/min ≥ | 30 | |

| 10 | Peel strength with cement mortar/(N/mm) | No processing ≥ | 1.5 |

| Heat treatment ≥ | 1.0 | ||

| 11 | Peel strength after immersion in cement mortar (N/mm) ≥ | 1.5 | |

| 12 | Thermal ageing (70℃, 168h) | Tensile retention rate/% | 90 |

| Elongation retention rate/% | 80 | ||

| Low temperature flexibility (-18℃) | No cracks | ||

| 13 | Dimensional change/ % | ±1.0 | |

| 14 | Thermal stability | No bulging, smooth, with maximum curling of polymer film or tire base edge not exceeding 1/4 of the side length | |

Key Features

- Upper surfacing uses high-strength polymer film (PF) that provides reliable dimensional stability, strong UV resistance, and good performance at low temperatures.

- The combination of physical adhesion, tenon effect, and chemical cross-linking reaction allows the membrane to form a continuous, integral waterproof layer with the substrate, delivering long-term bond strength and resistance to environmental stress.

- When installed using the paving method on roofs, it requires no special preparation of uneven substrates, no primer coat, and no cement mortar or paste for bonding — the self-adhesive layer directly adheres to the base with high resistance to puncture and damage.

- Offers effective waterproofing performance that prevents both liquid water and water vapor penetration into the structure.

- The modified asphalt compound exhibits high creep resistance and excellent adaptability to substrate movement and deformation, making it suitable for a wide range of roof waterproofing membrane applications and different construction conditions.

Applications

This self-adhesive modified asphalt membrane is designed primarily for non-exposed applications, making it appropriate for underground structures and indoor engineering projects.

It performs well in complex waterproofing scenarios, including open-cut subways, tunnels, water tanks, and water channels. The cold-applied installation process — requiring no open flames — provides clear advantages in confined spaces or areas where torch-on methods are prohibited due to safety regulations.

Common uses include:

- Below-grade waterproofing membrane for walls on foundations and basements, where it adheres directly to concrete surfaces.

- As a waterproofing membrane for concrete in retaining structures, parking garages, and planter boxes.

- Horizontal or vertical applications on non-exposed roofs under ballast, insulation, or green roof systems (as an alternative to traditional EPDM roofing self adhesive waterproofing membrane in certain non-UV-exposed setups).

- Self adhesive foundation waterproofing membrane systems for new construction or retrofit projects requiring reliable protection against groundwater ingress.

Its ability to bond to prepared substrates without heat makes it particularly practical for sensitive environments where hot-work permits are restricted.

Installation Methods

The JY-ZSH is a self adhesive bituminous waterproofing membrane applied using a cold, peel-and-stick process that requires no open flames or hot asphalt, making it suitable for non-exposed areas and sites with fire restrictions.

Standard installation steps include:

- Prepare the substrate by ensuring it is clean, dry, stable, and free of dust, oil, loose particles, or protrusions. Minor unevenness is typically accommodated without extensive leveling.

- Apply a bituminous primer if recommended for the specific substrate conditions to improve adhesion (many installations proceed without primer on suitable concrete surfaces).

- Unroll the membrane, align it properly, and gradually peel away the silicon-coated release film from the underside while pressing the adhesive side firmly onto the substrate.

- Use a heavy roller to press the entire surface, expelling air pockets and ensuring full contact for strong bonding.

- Overlap adjacent sheets by the specified amount (usually 75-100 mm on side laps and 150 mm on end laps), removing the release strip at overlaps and rolling seams to create a continuous seal.

- Treat details around penetrations, corners, and transitions with additional membrane pieces or compatible sealants.

This method works well for underground structures, tunnels, and as a basement waterproofing membrane, where direct adhesion to concrete provides reliable protection against groundwater. Always follow site-specific conditions and local guidelines for best results.

Customer Reviews

John M., Contractor, USA ★★★★☆ "We used this membrane for a basement retrofit project. The self-adhesive backing stuck well to the concrete without needing a primer in most areas, and the overlaps sealed reliably after rolling. It's been six months with no signs of moisture ingress so far. Solid option when looking for self adhesive waterproofing membrane for sale."

Maria S., Builder, Canada ★★★★★ "Applied it on foundation walls in a cold climate. The material remained flexible during installation at around 5°C, and adhesion held up through the winter. It adapts to minor substrate movement better than the self adhesive hdpe waterproofing membrane we've tried before. No issues after one full season."

Ahmed K., Project Manager, UAE ★★★★☆ "Good for underground water tank lining where torching isn't allowed. The peel-and-stick method sped up installation in a confined space. Bond strength seems consistent, and it handles the heat here without softening noticeably. Prefer it over tpo roofing self adhesive waterproofing membrane for non-exposed applications like this."

Li Wei, Engineer, China ★★★★☆ "Used on a tunnel section. The 2mm thickness provided decent puncture resistance during backfill, and the self-adhesive layer formed a continuous barrier without extra sealants at seams. Performs as expected in damp conditions."

Project Case Studies

Case 1: Basement Foundation Waterproofing – Residential Project, North America In a new single-family home construction located in an area with high groundwater levels, the JY-ZSH membrane (1.5 mm thickness) was selected for exterior vertical application on poured concrete foundation walls. The substrate was cleaned and primed only in spots with surface inconsistencies. Crews unrolled and applied the sheets directly, achieving good adhesion without heat. Overlaps were rolled thoroughly to ensure seam integrity. After backfilling with soil and gravel, the system has shown no signs of water intrusion or delamination over two years of monitoring, providing reliable below-grade protection.

Case 2: Underground Tunnel Lining – Infrastructure Project, Asia For a municipal utility tunnel in an urban setting, the 2.0 mm version was used to line concrete segments where open-flame methods were strictly prohibited for safety reasons. Installation involved peeling the release film and pressing the membrane onto the prepared surface in a confined environment. The material's flexibility allowed it to conform to curved sections, and the self-adhesive overlaps formed watertight joints without additional mastics. Post-backfill inspections confirmed puncture resistance and continuous bonding, maintaining a dry interior since project handover.

Case 3: Concrete Water Tank – Municipal Water Storage Facility During the renovation of an existing concrete potable water reservoir, the membrane was applied to interior walls and floor to prevent leakage. The cold-applied peel-and-stick process minimized downtime and avoided risks associated with hot works near water infrastructure. Sheets were cut to fit around outlets and inlets, with careful rolling at details. The adhered layer has held up well under constant water exposure, passing multiple pressure tests and visual checks with no evidence of peeling or moisture migration.

Case 4: Non-Exposed Flat Roof – Commercial Building Retrofit, Europe On a low-slope concrete deck of an industrial warehouse, the JY-ZSH served as the primary waterproofing layer in a protected membrane roof assembly under insulation boards and gravel ballast. Unlike exposed systems such as pvc roofing self adhesive waterproofing membrane or tpo variants, this bituminous option offered a cheapest self adhesive waterproofing membrane solution for non-UV applications while accommodating deck movement. Installation handled minor surface irregularities effectively, and the fully adhered system has prevented leaks through several cycles of rain, snow, and temperature fluctuations. Note that for wet areas like bathrooms, a specialized waterproofing membrane for shower would be more appropriate.

|  |

|  |

About Our Factory

Shandong Great Ocean Waterproof Technology Co., Ltd. (formerly Weifang Juyang New Waterproof Materials Co., Ltd.) is located in Taitou Town, Shouguang City—the heart of China's largest waterproof materials production base. Established in 1999, we are a high-tech enterprise integrating research, production, and sales in the waterproofing industry.

Our facility covers 26,000 square meters and features multiple advanced production lines for membranes, sheets, and coatings. The product range includes polyethylene-propylene (polyester) polymer waterproof membranes, pvc membrane waterproofing, TPO waterproof membranes, specialized CPE membranes for high-speed rail, various self-adhesive polymer membranes, non-asphalt reactive pre-laid membranes, cross-laminated high-strength membranes, drainage boards, SBS/APP modified bitumen membranes, root-resistant puncture membranes, single- and dual-component polyurethane waterproof coating, JS polymer cement coatings, water-based polyurethane options, K11 Waterproof Coating (cementitious crystalline type), spray-applied rubber asphalt coatings, non-curing rubber asphalt coatings, and related accessories such as tapes and glues.

We maintain strong technical capabilities with experienced professionals, modern equipment, and comprehensive testing instruments to ensure consistent product quality. Our operations have earned certifications from national authorities, including full quality management compliance, ISO quality system certification, and product licenses.

Products are supplied across more than 20 provinces in China and exported to several international markets, with a focus on reliable performance for applications like roof waterproof coating. Operating under principles of integrity, practicality, and innovation, we aim to build long-term partnerships through competitive pricing and dedicated service.

![JY-ZSH High Strength Self-Adhesive Waterproofing Membrane [H]](https://great-ocean-waterproof.com/wp-content/uploads/2025/12/JY-ZSH-High-Strength-Self-Adhesive-Waterproofing-Membrane-H2_1.webp)

![JY-ZNU Self-Adhesive Polymer Waterproofing Membrane [N]](https://great-ocean-waterproof.com/wp-content/uploads/2025/12/JY-ZNU-Self-Adhesive-Polymer-Waterproofing-Membrane-N_1-300x300.webp)