JY-CCW tsemendipõhine läbilaskev kristalliline veekindel kate akrüülhappe veekindel kate

See toode on pulbriline jäik veekindel materjal, mis on valmistatud spetsiaalsest tsemendist, kvartsliivast ja muudest esmaklassilistest koostisosadest, mis on segatud multiaktiivsete kemikaalidega. Lihtsalt lisage vesi, et valmistada sile segu, seejärel kandke see tsementbetoonkonstruktsioonide aluspinnale. Pärast kõvenemist moodustab see betoonpinnale jäiga, kleepuva katte, samal ajal kui selle aktiivsed kemikaalid tungivad läbilaskvate veekandjate kaudu sügavale betooni. Need kemikaalid katalüüsivad lahustumatute kristallide moodustumist betooni silikaatidega, täites kapillaarpoorid ja mikropraod betooni tihendamiseks, pakkudes suurepärast veekindlust ja usaldusväärset veekindlust.

Toote tutvustus

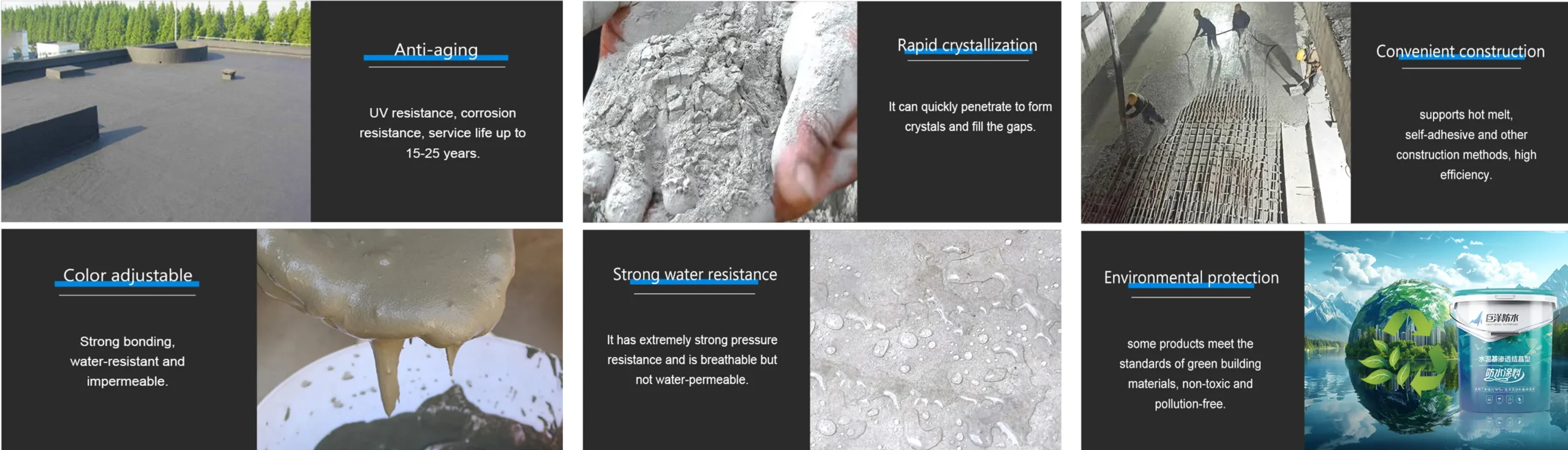

Product Features of JY-CCW Cement Based Permeable Crystalline Waterproof Coating

- Super Strong Penetration Capacity: Can penetrate over 5cm into the concrete surface, ensuring deep and thorough waterproof protection.

- Outstanding Anti-Seepage Performance: Sustains long-term resistance to high water pressure of over 120 meters, effectively preventing water infiltration.

- Uncompromised Waterproofing When Coating is Damaged: Waterproof performance remains unaffected even if the coating itself is damaged, avoiding total failure of waterproofing functions.

- High Resistance to Harmful Chemical Erosion: Shields concrete from corrosion by harmful chemicals, significantly improving the durability and service life of concrete structures.

- Green & Environmentally Friendly: Non-toxic, harmless and pollution-free, meeting environmental protection standards. It is safe for application in drinking water projects (e.g., water tanks, pipelines).

- Automatic Crack Repair: Rapidly seals microcracks of less than 0.4mm, reducing maintenance needs and maintaining long-term waterproof effectiveness.

- Long-Lasting Waterproof Effect: Provides durable waterproof protection, with stable performance even in long-term use.

- Secondary Impermeability & Self-Healing Capabilities: Possesses secondary anti-seepage ability to cope with potential water pressure changes; self-healing properties further enhance waterproof reliability.

- Anti-Corrosion, Aging Resistance & Steel Bar Protection: Resists aging caused by environmental factors (e.g., sunlight, temperature changes) and corrosion; effectively protects internal steel bars from rusting, safeguarding the integrity of concrete structures.

- Easy Construction: Simple application process, requiring no complex equipment or professional skills, which reduces construction difficulty and shortens construction time.

Ettevaatusabinõud

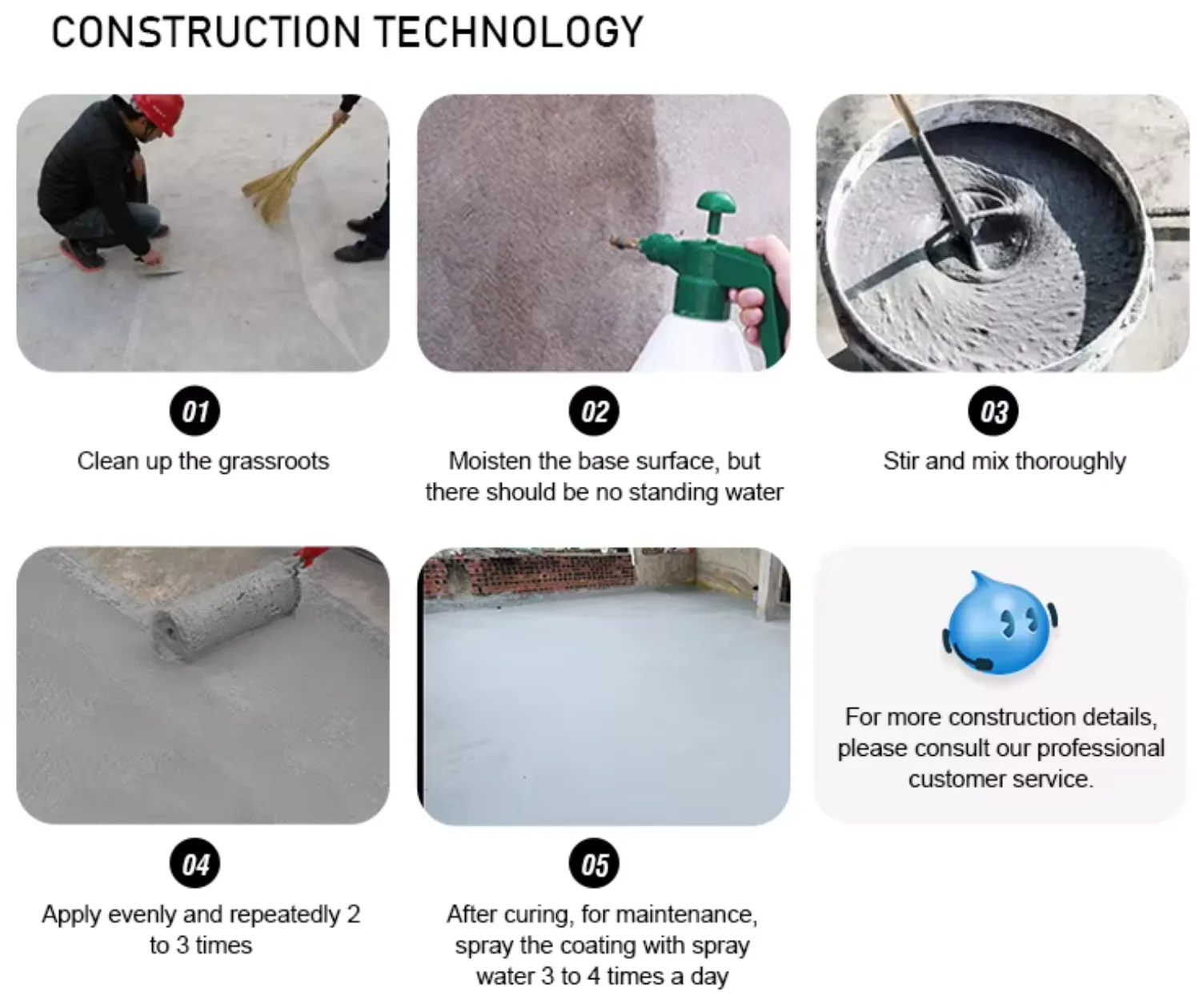

- Avoid construction in rain, fog, wind, or sandstorms.

- Use clean water for mixing and curing.

- Ensure a solid, clean base free of dust, oil, or loose material.

- Repair cracks, holes, and defects before application.

- Seal pipe joints with V-grooves and clamps.

- Maintain proper coating thickness; avoid over-mixing or adding water.

- Wait 36 hours before backfilling; protect coating from water for 7 days.

Toimivusindeks

| Ei. | Ese | Toimivusindeks | ||

|---|---|---|---|---|

| Mina | II | |||

| 1 | Stabiilsus | Qualified | ||

| 2 | Setting time | Set time min ≥ | 20 | |

| End time h ≤ | 24 | |||

| 3 | Flexural Strength MPa ≥ | 7d | 2.80 | |

| 28d | 3.50 | |||

| 4 | Compressive strengthMPa ≥ | 7d | 12.0 | |

| 28d | 18.0 | |||

| 5 | Strong adhesion on damp substrate a/MPa ≥ | 1.0 | ||

| 6 | Anti-seepage pressure(28d) MPa ≥ | 0.8 | 1.2 | |

| 7 | Second anti-seepage pressure(56d) MPa ≥ | 0.6 | 0.8 | |

| 8 | Osmotic pressure ratio(28d) % | 200 | 500 | |

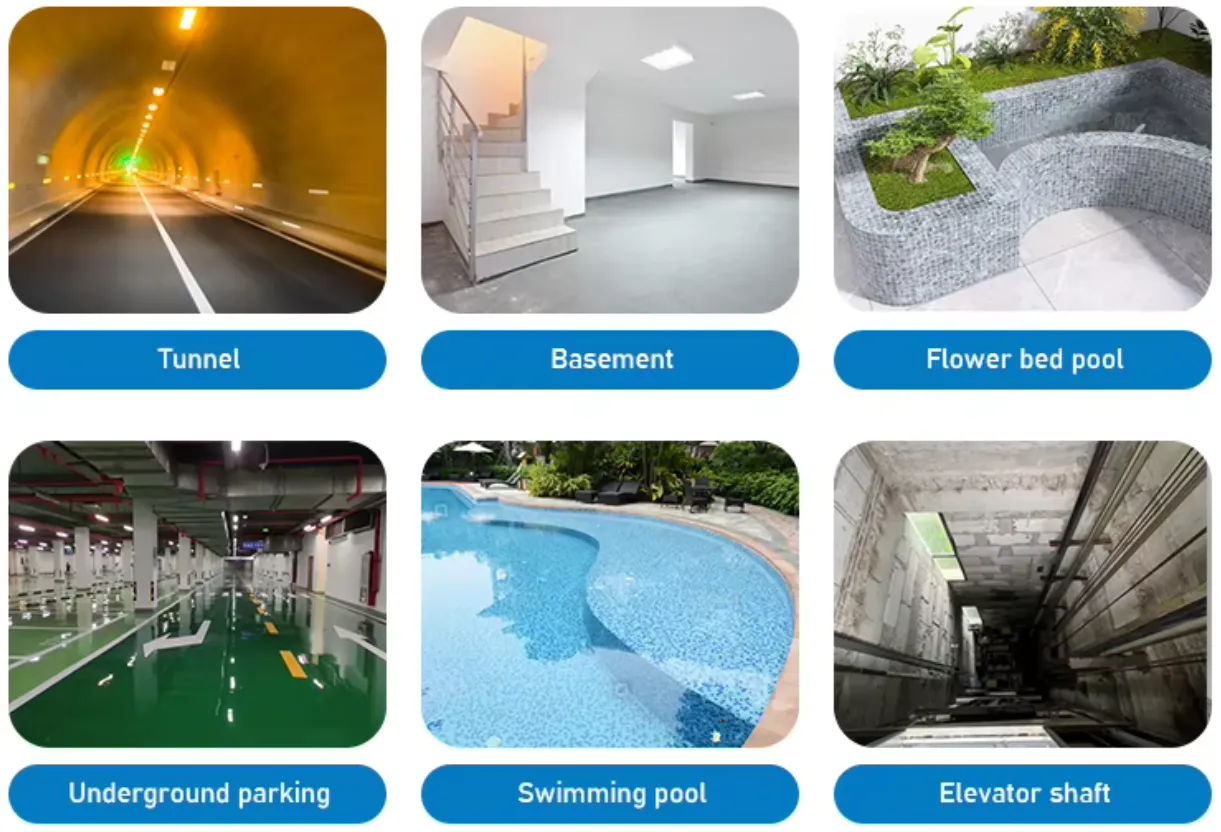

Ehitusmeetod

Brushing Method (Slurry)

Base Treatment:Clean base of slurry, alkali, dust, oil; roughen surface; rinse with high-pressure water.

Wet Base:Fully wet base; keep moist, no standing water.

Segamine

- Ratio: powder : water = 1 : (0.35–0.4)

- Add water first, then powder; stir evenly.

- Use within 20 min; no re-adding water.

Taotlus

- Brush evenly with stiff brush.

- Next coat after surface turns white.

- If >12 hrs, re-wet before coating.

- Dosage: 1.4–1.7 kg/m²

- Thickness: 1.0 mm (±0.05 mm)

Dry Spreading Method

- Spread 1.5 kg/m² on semi-set concrete.

- Press in with wooden trowel + polisher; calender surface.

Kõvenemine

- Keep wet ≥72 hrs (7 days ideal).

- Spray water or cover with wet cloth.

- Protect from rain; no acid cleaning.

Taotlus

Ehituse kirjeldus

Klientide arvustused

John D., United States I've used the JY-CCW Cement Based Permeable Crystalline Waterproof Coating on a basement renovation project. It mixed easily with water and applied smoothly to the concrete walls. After a few months, it held up well against minor water seepage from heavy rains, and I noticed no rust on the embedded rebar. The penetration depth seems solid, but it does require careful surface preparation to avoid uneven coverage. Overall, a reliable option for below-grade waterproofing.

Anna K., Germany As a structural engineer, I applied this acrylic acid waterproof coating to a tunnel repair job. The self-healing property worked as described for small cracks under 0.4 mm, which prevented further water ingress over time. It's resistant to aging in damp conditions, and the anti-corrosion feature is a plus for long-term durability. Application was straightforward, though curing needs consistent moisture for best results. It performed adequately in our tests.

Rajesh P., India We used the JY-CCW on a water storage tank in a rural area. The environmental aspect is appealing since it's non-toxic and suitable for drinking water projects—no odors or harmful residues. It provided good impermeability against monsoon leaks, and the crystals formed effectively to seal pores. However, the dosage needs precise measurement to avoid waste. It's a practical choice for infrastructure in humid climates.

Sophie L., Australia Applied this cement-based permeable crystalline coating to our swimming pool's concrete shell. It integrated well with the substrate, offering decent resistance to chemical exposure from pool treatments. The waterproofing held during the wet season, with no visible cracking or peeling after six months. Easy to work with, but it sets quickly, so you have to plan your batches. Satisfied with the outcome for recreational use.

Li Wei, Hiina In a sewage treatment plant upgrade, the JY-CCW Acrylic Acid Waterproof Coating was used on tanks and pipes. It showed good anti-seepage pressure and protected against corrosion from wastewater. The material's rigidity helped in maintaining structural integrity, and it didn't require heavy equipment for application. One note: it performs better on damp surfaces, so timing is key. It's functional for industrial settings.

Maria G., Brazil For a bridge foundation project in a flood-prone area, this coating provided secondary impermeability that helped with high water pressure resistance. The crystals filled microcracks effectively over time, reducing maintenance needs. It's pollution-free, which aligns with our eco-regulations. Mixing and brushing were uncomplicated, though full curing took the recommended 72 hours. A solid product for civil engineering applications.

Meie tehase kohta

Great Ocean Waterproof Technology Co., Ltd. (formerly Weifang Great Ocean New Waterproof Materials Co., Ltd.) is strategically located in Taitou Town Government Resident, Shouguang City—the heart of China's largest waterproof materials production base. Established in 1999, we are a national high-tech enterprise specializing in the integration of scientific research, production, and sales within the waterproofing industry.

Our factory spans an impressive 26,000 square meters and, through years of innovation and development, is equipped with multiple state-of-the-art production lines for roll sheets, sheet materials, and coatings. We proudly manufacture a wide range of premium products, including the JY-CCW Cement Based Permeable Crystalline Waterproof Coating and Acrylic Acid Waterproof Coating, alongside dozens of other solutions such as polyethylene polypropylene (polyester) polymer waterproofing membranes, PVC waterproofing membranes, TPO waterproofing membranes, chlorinated polyethylene (CPE) waterproofing membranes for high-speed rail, polymer polypropylene self-adhesive waterproofing membranes, non-asphalt reactive pre-laid polymer self-adhesive waterproofing membranes, strong cross-laminated film polymer reactive bonding waterproofing membranes, protective drainage boards, SBS/APP modified bitumen waterproofing membranes, asphalt-based self-adhesive waterproofing membranes, polymer modified bitumen root-resistant puncture waterproofing membranes, metal-based polymer root-resistant puncture waterproofing membranes, root-resistant polyethylene polypropylene (polyester) waterproofing membranes, root-resistant PVC waterproofing membranes, single-component polyurethane waterproof coatings, dual-component polyurethane waterproof coatings, polymer cement (JS) composite waterproof coatings, veepõhised (951) polüuretaanist veekindlad katted, specialized dry powder adhesives for polyethylene polypropylene (polyester), spray-applied quick-setting rubber asphalt waterproof coatings, non-curing rubber asphalt waterproof coatings, exterior wall transparent waterproof glue, high-elastic liquid membrane waterproof coatings, self-adhesive asphalt waterproof tapes, and butyl rubber self-adhesive tapes.

Backed by a robust technical team of expert professionals, advanced equipment, and comprehensive testing instruments, we ensure stable and reliable product quality certified by national authoritative inspection agencies. Our accolades include the Ministry of Agriculture's "Comprehensive Quality Management Compliance" title, ISO quality assurance system certification, recognition as a "Nationally Authoritative Tested Qualified Product" by the China Quality Inspection Association, Shandong Province "Industrial Construction Product Filing Certificate," and "Industrial Product Production License."