ממברנת איטום עמידה בפני ניקוב שורש אספלט מעובדת מפולימר JY-NSB

ממברנת האיטום עמידה בפני ניקוב שורשים מאספלט מעובד מפולימר JY-NSB מיוצרת באמצעות אלסטומר תרמופלסטי סטירן בוטדיאן סטירן (SBS) כמשנה, עם מעכבי שורשים כימיים כדי להגביל את צמיחת שורשי הצמחים לתוך שכבת האיטום. היא כוללת בד בסיס פוליאסטר לחיזוק ומשטח סרט פוליאתילן (PE) כמחסום, המאפשר לגלגל אותה לצורת יריעה עבור יישומי איטום. כיצרנית בסין, Great Ocean Waterproof מספקת חומר זה ישירות מהמפעל שלנו, והתמחור זמין לפי בירור.

מבוא למוצר

ממברנת האיטום עמידה בפני ניקוב שורשים מאספלט מעובדת מפולימר JY-NSB היא חומר דמוי יריעה המיועד ליישומי איטום בהם חדירת שורשי צמחים מהווה דאגה. היא משלבת אלסטומר תרמופלסטי סטירן-בוטדיאן-סטירן (SBS) כמשנה בבסיס האספלט, יחד עם מעכבי שורשים כימיים כדי להגביל את צמיחת השורשים לכיוון שכבת האיטום. המבנה כולל חיזוק מבד פוליאסטר לחוזק נוסף, כאשר סרט פוליאתילן (PE) על פני השטח והתחתית משמש כשכבות מחסום.

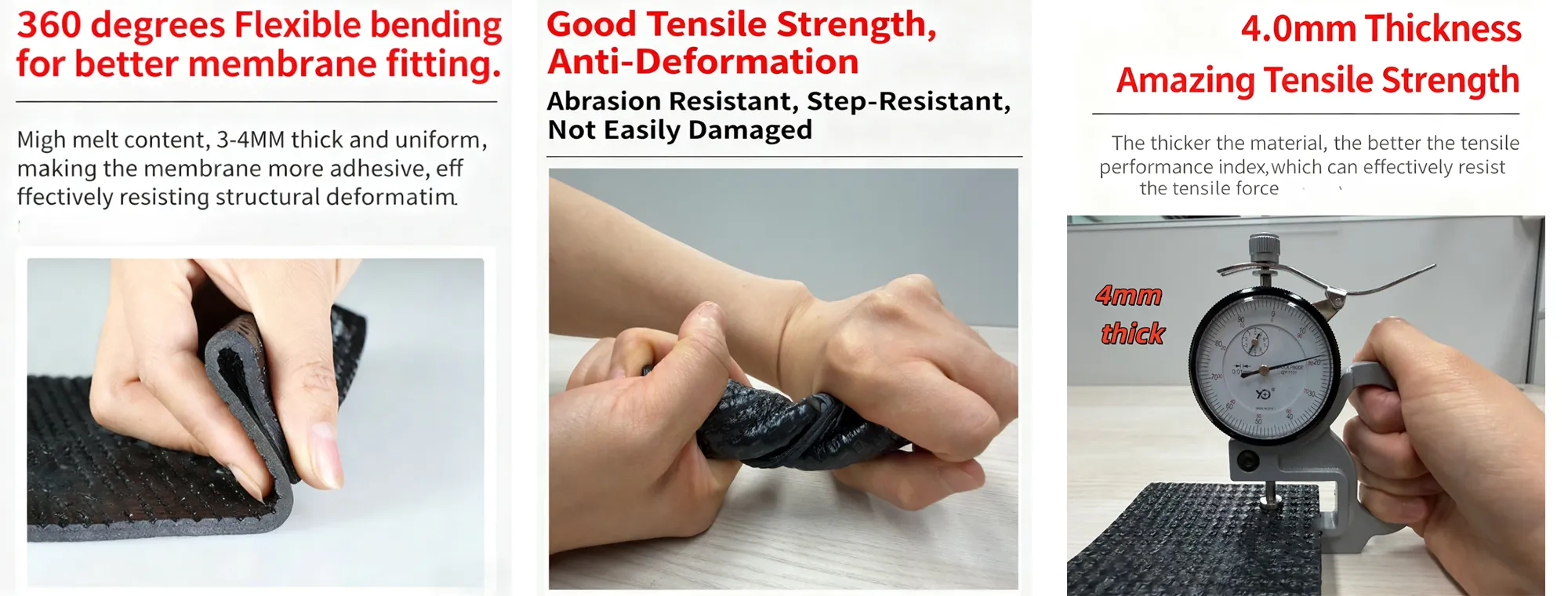

מידות סטנדרטיות לממברנה זו הן 4.0 מ"מ עובי, 10 מטר אורך ו-1.0 מטר רוחב. היא מיושמת בדרך כלל בגגות ירוקים, אזורי שתילה במרתפים ופרויקטים דומים של בנייה הדורשים גם איטום וגם עמידות לשורשים. החומר מציע תאימות לאקלים חם וקר בשל סבילותו לטמפרטורה, והוא מספק עמידות בפני קורוזיה ובליה בתנאי סביבה סטנדרטיים. ההתקנה כרוכה בדרך כלל בכיפוף הממברנה למקומה לכיסוי במערכות איטום של מבנים.

מאפייני ביצועים

- מספק עמידות בפני חדירת שורשי צמחים מבלי לפגוע בגדילת הצמחים הרגילה, ותומך בתפקוד איטום לטווח ארוך.

- מציע עמידות בפני קורוזיה ועובש.

- כולל בד בסיס פוליאסטר כשכבת חיזוק העמידה בפני ניקוב, שחיקה וקריעה, מה שמחזק את החומר ומגן מפני נזק מהמשטחים העליונים והתחתונים.

- בעל חוזק מתיחה של לפחות 800N/50 מ"מ והתארכות של לפחות 40%, המאפשרים יכולת הסתגלות להתכווצות, עיוות וסדקים של הבסיס.

- שומר על שלמות מבלי לזרום בטמפרטורות גבוהות עד 105°C או להיסדק בטמפרטורות נמוכות עד -25°C, ומכסה מגוון תנאי הפעלה.

- במהלך הפעלת המבער, הוא נוטה לייצר שמן; שילוב מרכיבים שעברו שינוי יכול להרחיב את שטח החימום ליחידה, להוריד את נקודת ההיתוך, להפחית את טמפרטורת החימום הנדרשת ולהפחית את פליטת הגזים.

מדד ביצועים

| לֹא. | פָּרִיט | אינדיקטורים טכניים | |

|---|---|---|---|

| 1 | תכולה מסיסה (גרם/מ"ר) ≥ | 4 מ"מ | 2900 |

| 2 | עמידות בחום | פריטי בדיקה | בסיס צמיג לא דליק |

| ℃ | 105 | ||

| ≤ מ"מ | 2 | ||

| תופעה ניסיונית | אין טפטוף או טפטוף | ||

| 3 | גמישות בטמפרטורה נמוכה/℃ | -25 | |

| 4 | אטימות/30 דקות | אין סדקים 0.3 מגה פסקל |

|

| 5 | כוח משיכה | כוח מתיחה שיא מקסימלי/(N/50 מ"מ) ≥ | 800 |

| תופעה ניסיונית | במהלך תהליך המתיחה, לא היה סדקים או הפרדה של ציפוי האספלט מבסיס הצמיג במרכז הדגימה. | ||

| 6 | קצב התארכות | התארכות מתיחה שיא מקסימלית / (N / 50 מ"מ) ≥ | 40 |

| 7 | עלייה במסה לאחר טבילה במים % ≤ | PE, S | 1.0 |

| מ | 2.0 | ||

| קצב שימור מתיחה /% ≥ | 90 | ||

| קצב שימור התארכות /% ≥ | 80 | ||

| גמישות בטמפרטורה נמוכה/℃ | -20 | ||

| אין סדקים | |||

| שינוי ממדי /% ≤ | 0.7 | ||

| אובדן מסה /% ≤ | 1.0 | ||

| 8 | הזדקנות תרמית | 1.5 | |

| 9 | חוזק קילוף חיבור / (N/mm) ≥ | 1.0 | |

| 10 | עמידות בפני קורוזיה לעובש | רמה 1 | |

| 11 | עובי ציפוי האספלט על המשטח התחתון של חומר הגליל/מ"מ ≥ | 1.0 | |

| 12 | אקלים מלאכותי מאיץ הזדקנות | הוֹפָעָה | אין החלקה, זרימה או טפטוף |

| קצב שימור מתיחה /% ≥ | 80 | ||

| גמישות בטמפרטורה נמוכה/℃ | -10 אין סדקים |

יישומים

ממברנת איטום JY-NSB, עמידה בפני ניקוב שורשים, עשויה מאספלט מעובד מפולימר, מיועדת לשימוש באזורים בהם איטום חייב לעמוד בפני חדירת שורשים מצמחייה, תוך מתן הגנה אמינה מפני לחות. יישומים נפוצים כוללים:

- גגות ירוקים וגני גגותמתאים לגגות שטוחים או בעלי שיפוע נמוך עם אדמה וצמחים, כאשר השכבות הכימיות מעכבות שורשים ועמידות בפני ניקוב מונעות נזק משורשים תוך שמירה על שלמות עמידות למים.

- אדניות וטרסות מעוצבותאידיאלי למרפסות, טרסות או דקי פודיום עם שתילה משולבת, המציע גמישות להתאמת תנועות קלות של פני השטח ועמידות בפני חשיפה סביבתית.

- מבנים תת-קרקעיים עם צמחייהמשמש במרתפים, מנהרות או קירות תמך ליד עצים או שיחים, שבהם שורשים עלולים לפגוע במחסום האיטום.

- אזורי נוף והשקיהניתן ליישום בפארקים, מגרשי גולף או סביבות חקלאיות עם מערכות השקיה, ומספק הגנה עמידה מפני חדירת מים ושורשים.

- מבני מסחר ומגוריםיעיל עבור גגות שטוחים או פודיומים במבנים מרובי קומות, במיוחד בסביבות עירוניות עם שטח מוגבל לצמחייה ירוקה.

לקבלת התוצאות הטובות ביותר, יש לוודא הכנה והתקנה נאותות של המשטח בהתאם להנחיות היצרן, ולקחו בחשבון תאימות עם חוקי הבנייה המקומיים.

הסבר מפורט על הגנה מפני ניקוב שורשים בממברנות איטום

הגנה מפני ניקוב שורשים מתייחסת למאפייני העיצוב הייעודיים בממברנות איטום המונעים משורשי צמחים לחדור ולפגוע בשלמות שכבת האיטום. זה קריטי במיוחד ביישומים כמו גגות ירוקים, טרסות צמחייה, מרתפים עם גינון או מבנים תת-קרקעיים שבהם קיימת צמחייה מעל או סביב מערכת האיטום. ללא הגנה מספקת, שורשי צמחים אגרסיביים - כמו אלה של עצים, שיחים או מינים פולשים - יכולים לצמוח לתוך הממברנה ודרכה לאורך זמן, מה שמוביל לדליפות, נזק מבני ותיקונים יקרים. בממברנות אספלט שעברו שינוי SBS כמו JY-NSB, הגנה מפני ניקוב שורשים מושגת באמצעות שילוב של מחסומים כימיים ופיזיים, המבטיחים ביצועי איטום לטווח ארוך תוך מתן אפשרות לצמיחה תקינה של צמחים במקומות אחרים.

מדוע הגנה מפני ניקוב שורשים נחוצה

בסביבות צמחייה, שורשי צמחים מחפשים באופן טבעי מים וחומרי הזנה, ולעתים קרובות משתרעים עמוק ומפעילים לחץ על החומרים שמתחת. ממברנות איטום סטנדרטיות ללא עמידות שורשים עלולות להיכשל תוך מספר שנים עקב חדירת שורשים, מה שיוצר נתיבים לחדירת מים. הגנה מפני ניקוב שורשים מטפלת בכך על ידי:

- שמירה על יעילות המחסום האיטום לאורך תקופות ממושכות (בדרך כלל 20-30 שנה או יותר בתנאים מתאימים).

- צמצום צורכי התחזוקה בפרויקטים של בנייה ירוקה, שבהם קיימות ועמידות הן בראש סדר העדיפויות.

- עמידה בתקני התעשייה עבור גגות ירוקים ושטחים צמחיים, בהם ממברנות חייבות לעמוד בפני לחצים ביולוגיים לצד גורמים סביבתיים כמו חשיפה לקרינת UV, תנודות טמפרטורה ועומסים מכניים.

כיצד פועלת הגנה מפני ניקוב שורשים בממברנות שעברו שינוי SBS

ממברנות אספלט מעובדות SBS (סטירן-בוטדיאן-סטירן) משלבות עמידות בפני ניקוב שורשים בעיקר באמצעות מעכבי כימיקלים משולבים ומבנים פיזיים מחוזקים. להלן פירוט המנגנון:

- מעכבי שורשים כימיים:

- אלו הם תוספים מיוחדים המעורבבים בתרכובת האספלט במהלך הייצור. הם משחררים חומרים בעלי רעילות נמוכה המונעים צמיחת שורשים ספציפית לכיוון השכבה האיטומה מבלי לפגוע במערכת האקולוגית הצמחית הכוללת.

- המעכבים פועלים על ידי יצירת "אזור דוחה שורשים" סביב הממברנה. כאשר שורשים מתקרבים, הם נתקלים באותות כימיים, אשר מפנים את הצמיחה הרחק מהממברנה או עוצרים את ההתארכות בכיוון זה. לעתים קרובות מושגת פעולה זו באמצעות תרכובות כמו מעכבים מבוססי נחושת או אורגניים אשר מפריעים להתפתחות קצות השורשים.

- במוצרים כמו JY-NSB, מעכבים אלה מבטיחים שהממברנה לא רק מונעת ניקוב אלא גם שומרת על בריאות הצמח על ידי הימנעות מקוטלי עשבים רחבי טווח שעלולים להרוג צמחייה שמעליה.

- מחסומים פיזיים וחיזוקים:

- בסיס הממברנה מחוזק בחומרים כמו בד פוליאסטר, המספק חוזק מתיחה ועמידות בפני קריעה או סדקים תחת לחץ השורשים.

- שכבות פני השטח והתחתית, העשויות לרוב מיריעת פוליאתילן (PE), משמשות כמחסומים נוספים. יריעות אלו עמידות ואטומות, ומוסיפות מגן מכני מפני מגע ראשוני עם השורשים.

- העובי הכולל (למשל, 4.0 מ"מ ב-JY-NSB) תורם לעמידות בפני ניקובים, שכן ממברנות עבות יותר יכולות לעמוד טוב יותר בכוח האיטי והמתמשך של התפשטות השורשים. מבנה רב-שכבתי זה יוצר יתירות: גם אם שורשים פורצים את השכבה החיצונית, חיזוקים פנימיים שומרים על אטימות למים.

- פונקציונליות כפולה:

- העיצוב מציע גם איטום וגם עמידות בפני שורשים במוצר אחד, ובכך מבטל את הצורך ביריעות מחסום נפרדות לשורשים. שילוב זה מפשט את ההתקנה ומפחית את עלויות החומרים.

- במהלך היישום, הממברנה בדרך כלל מודבקת באמצעות מבער או מודבקת ביריעות חופפות, ויוצרת איטום רציף. לאחר ההתקנה, היא עמידה לא רק בפני שורשים אלא גם לעייפות מתנועת הקרקע, לחץ מים ופגיעה סביבתית.

תקני בדיקה וביצועים

עמידות בפני ניקוב שורשים מאומתת באמצעות בדיקות סטנדרטיות, כגון אלו המפורטות ב-EN 13948 או בפרוטוקולים דומים, שבהם נחשפות הממברנות לצמחים גדלים (למשל, מינים אגרסיביים כמו במבוק או פירקנתה) בסביבות מבוקרות לתקופות של עד שנתיים. ממברנות מוצלחות אינן מראות חדירת שורשים תוך שמירה על אטימות. אפשרויות שעברו שינוי SBS כמו JY-NSB עולות לעיתים קרובות על הדרישות הבסיסיות, ומציעות עמידות משופרת לעייפות (נגד קרעים, נגד סדקים) ותאימות לאקלים שונים.

מגבלות ושיטות עבודה מומלצות

למרות היותה יעילה, הגנה מפני ניקוב שורשים אינה חסינה מטעויות כנגד שורשים תוקפניים במיוחד או התקנה לקויה. שיטות עבודה מומלצות כוללות:

- הבטחת עומק אדמה וניקוז נאותים מעל הממברנה כדי למזער את הלחץ על השורשים.

- בדיקות שוטפות באזורים בסיכון גבוה.

- שילוב עם לוחות ניקוז תואמים או גיאוטקסטילים לקבלת ביצועי מערכת אופטימליים. לסיכום, הגנה מפני ניקוב שורשים בממברנות שעברו שינוי SBS כמו JY-NSB משלבת הרתעה כימית עם חוזק פיזי כדי להגן על איטום בסביבות צמחייה, תוך קידום בנייה עמידה וידידותית לסביבה.

השוואה בין ממברנות שעברו שינוי SBS (למשל, JY-NSB) לממברנות שעברו שינוי APP וממברנות PVC

ממברנות אספלט שעברו שינוי SBS, כגון ממברנת איטום עמידה בפני ניקוב שורשים מדגם JY-NSB Polymer Modified Asphalt, משתמשות באלסטומר סטירן-בוטדיאן-סטירן בבסיס אספלט לצורך גמישות, לעתים קרובות עם תכונות נוספות כמו מעכבי שורשים כימיים. ממברנות שעברו שינוי APP מערבבות פוליפרופילן אטקטי לתוך אספלט לצורך תכונות פלסטומר, בעוד שממברנות PVC הן יריעות תרמופלסטיות חד-שכבתיות העשויות מפוליוויניל כלוריד. שלושתן משמשות באיטום גגות, מרתפים ומבנים דומים, אך הן נבדלות בהרכבן, בביצועיהן ובהתאמהן.

הטבלה הבאה מסכמת את ההבדלים העיקריים בהתבסס על נתוני תעשייה סטנדרטיים:

| אַספֶּקט | SBS-Modified ממברנות (למשל, JY-NSB) | ממברנות שעברו שינוי APP | ממברנות PVC |

|---|---|---|---|

| הרכב החומר | אספלט שעבר שינוי באלסטומר SBS לגמישות; כולל חיזוקים כמו פוליאסטר ומחסומים כמו סרט PE; תוספים אופציונליים כגון מעכבי שורשים. | אספלט שעבר שינוי עם פלסטומר APP לקשיחות; חיזוקים דומים אפשריים אך מתמקדים בתכונות פלסטיות. | יריעת פולימר תרמופלסטית, לרוב מחוזקת בפוליאסטר או פיברגלס; מנוסחת ליציבות UV ועמידות בפני כימיקלים. |

| גמישות ואלסטיות | גמישות גבוהה, המאפשרת התאמה טובה יותר לתנועת המצע והתפשטות/התכווצות תרמית. | גמישות נמוכה יותר, נוטה יותר לסדקים תחת תנועה משמעותית או בסביבות דינמיות. | גמישות בינונית; יכול להיות גמיש במהלך ההתקנה אך עלול להתקשח עם הזמן בתנאים משתנים. |

| עמידות טמפרטורה | מתפקד היטב באקלים קר, עם גמישות טובה בטמפרטורות נמוכות (עד -20°C או פחות בניסוחים מסוימים); מתאים לאזורים עם מחזורי הקפאה-הפשרה. | מתאים יותר לאקלים חם וחשיפה גבוהה לקרינת UV, עם עמידות גבוהה יותר לחום אך ביצועים מופחתים בקור קיצוני. | יעיל באקלים חם עם עמידות מובנית לקרינת UV; פועל בטווח רחב אך עלול להתפורר בקור ממושך. |

| שיטת יישום | מיושם בדרך כלל באמצעות צריבה, אספלט חם או הידבקות עצמית; דורש טיפול זהיר כדי למנוע נזק במזג אוויר קר; מערכות רב שכבתיות נפוצות. | לרוב מיושם באמצעות מבער; זורם בקלות רבה יותר במהלך ההתקנה, מה שהופך אותו לעדיף עבור אזורים קטנים או מורכבים. | מותקן כיריעת יחידה באמצעות ריתוך בחום, הידוק מכני או נטל; התקנה מהירה יותר עבור שטחים גדולים. |

| עמידות ואריכות ימים | עמידות משופרת לעייפות מתנועת הבניין; ניתן להוסיף עמידות בפני ניקוב שורשים באמצעות מעכבים כימיים; אורך חיים טיפוסי 15-25 שנים עם יתירות רב שכבתית. | עמידות טובה בפני קרינת UV ובלאי; עמיד בדרך כלל בתנאי חום גבוהים ויציבים, אך ייתכן שיידרשו שכבות מגן נוספות באקלים משתנה. | שכבה אחת עם עמידות חזקה בפני כימיקלים ובליה; תפרים מרותכים מפחיתים את סיכוני הדליפה; מחזיק מעמד לרוב 20-30 שנה. |

| עֲלוּת | בדרך כלל גבוה יותר עקב גומי סינתטי ותכונות נוספות כמו מעכבי שורשים; התקנה עתירת עבודה. | לעתים קרובות יותר חסכוני עבור יישומים בסיסיים. | עלויות ראשוניות גבוהות יותר מקוזזות על ידי התקנה מהירה יותר וצורך תחזוקה נמוך יותר. |

| שימושים נפוצים | גגות ירוקים, אזורים צמחיים, מרתפים ואזורים עם חורפים קרים או פעילות סייסמית, בהם נדרשת עמידות וגמישות של שורשים. | גגות שטוחים באזורים חמים, מבנים מסחריים ויישומים המעדיפים יציבות חום על פני גמישות. | גגות שטוחים מסחריים, סביבות עם חשיפה לכימיקלים, או עיצובים חסכוניים באנרגיה הדורשים משטחים מחזירי אור. |

ביקורות לקוחות

ג'ון מארצות הברית אני משתמש בממברנת איטום JY-NSB פולימר מעובדת אספלט עמידה בפני ניקוב שורשים בפרויקט גינת הגג שלי כבר כשנה. עובי 4 מ"מ ובסיס לבד סיבי פוליאסטר עמדו היטב כנגד שורשי צמחי הירקות שלי, ומספקים עמידות אמינה בפני ניקובים בהתאם למפרט. לא שמתי לב לדליפות במהלך גשמים עזים, ונראה כי חוזק המתיחה שלו, כ-800 ניוטון/50 מ"מ, מתמודד עם תנועות קלות של שכבת הבסיס ללא בעיות. ההתקנה הייתה פשוטה עם הכלים הנכונים, אם כי ארכה קצת יותר זמן מהצפוי עקב משקל החומר. בסך הכל, זוהי בחירה מוצקה לאזורים עם גידול צמחים.

אמה מהממלכה המאוחדת כגנן בלונדון, התקנתי את הממברנה הזו על גג ירוק של לקוח בקיץ שעבר. האספלט שעבר שינוי SBS עם מעכב שורשים כימי מציע עמידות טובה לחדירת שורשים משיחים, ושינוי הפולימר מוסיף גמישות עם קצב התארכות של לפחות 30%, מה שעזר להתמודד עם המשטח הלא אחיד. עד כה לא היו בעיות עם הצטברות מים, אפילו לאחר מספר חודשים רטובים, הודות לשכבת האיטום האטומה שלו. זו לא האפשרות הזולה ביותר, אבל היא מתפקדת כמתואר בנתונים הטכניים לעמידות בפני קורוזיה ומזג אוויר.

ליאם מאוסטרליה גרתי באזור מועד לשריפות יער, והייתי זקוק למשהו אמין לגג השטוח של הסככה שלי, שיכול להתמודד גם עם מים וגם עם חדירת שורשים פוטנציאלית מעצי אקליפטוס סמוכים. יריעת JY-NSB, ברוחב מטר אחד ואורך גליל של 7.5 מטר, עשתה את העבודה מבלי להיסדק תחת השמש החמה, הודות לעמידותה בחום של עד 80 מעלות צלזיוס. היישום דרש חפיפה זהירה כדי להבטיח כיסוי מלא, אך לאחר סיום היישום, הוא דורש תחזוקה מועטה. מרוצה מהתוצאות לאחר שישה חודשים, במיוחד מהעמידות לטחב בתקופות הלחות שלנו.

סופיה מגרמניה מרחתי את ממברנת האיטום הזו על גינת המרפסת שלי בברלין, שם החורפים יכולים להיות קשים. היא עמידה בפני ניקוב שורשים מעציצי העשבים שלי ביעילות, עם ה... ציפוי ביטומן מעובד מספק הידבקות חזקה ועמידות בפני ניקובים העומדים בתקני EN. גמישות החומר בטמפרטורות נמוכות עד -20°C עומדת במחזורי הקפאה-הפשרה, אם כי הוא מעט כבד לעבודה לבד בעובי של 4 מ"מ. התוצאה הסופית היא חלל יבש מתחת, והוא תואם את המפרטים הבסיסיים של האיחוד האירופי עבור מוצרים כאלה.

קרלוס מספרד עבור המרפסת שלי במדריד, שבה נטועים עצי זית בקרבת מקום, JY-NSB מנע כל נזק משורשים לשכבת האיטום במהלך שמונת החודשים האחרונים. עמידותו בטמפרטורות גבוהות ונמוכות מתאימה לאקלים החם שלנו, ובסיס האספלט אינו פולט ריחות חזקים במהלך ההתקנה. הכיסוי שווה לרוחב של מטר אחד, והוא משתלב היטב עם מערכות ניקוז קיימות, מגובה ביציבותו הכוללת ובתכונות עמידותו בפני מזג אוויר. פתרון פרקטי לתנאים ים תיכוניים.

שאלות נפוצות

ממה עשויה ממברנת איטום עמידה בפני ניקוב שורשים של אספלט מעובד מפולימר JY-NSB? הממברנה מורכבת מציפוי אספלט שעבר שינוי SBS עם בסיס לבד פוליאסטר, המשלב מעכב שורשים כימי לעמידות נוספת בפני ניקוב. עוביה 4 מ"מ והיא זמינה בגלילים ברוחב 1 מטר ובאורך 7.5 מטר.

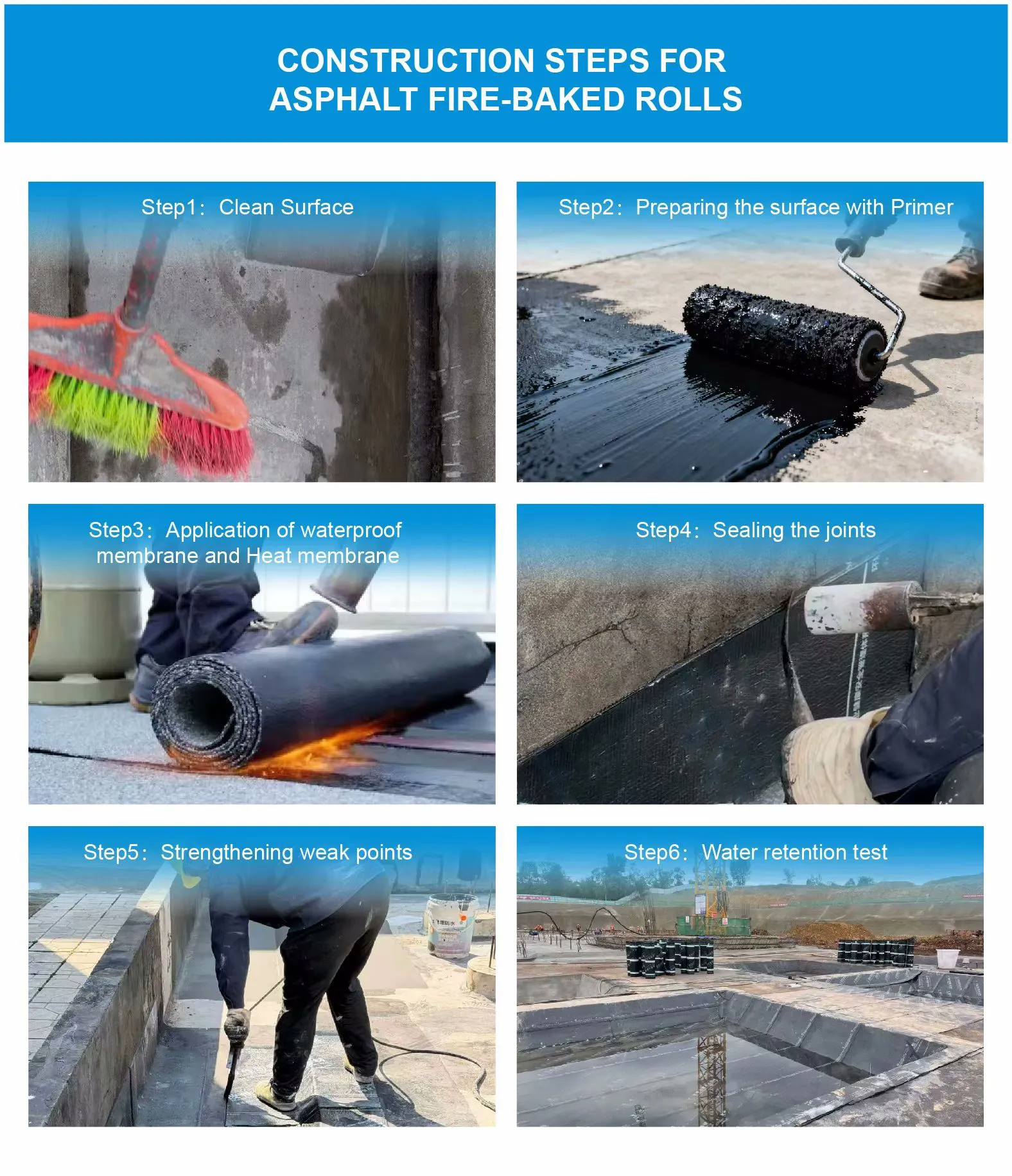

כיצד ניתן להתקין את ממברנת JY-NSB? ההתקנה כוללת בדרך כלל ניקוי המשטח, מריחת צבע יסוד במידת הצורך, ולאחר מכן גלישת הממברנה עם תפרים חופפים של לפחות 100 מ"מ. השתמשו במבער או באוויר חם להדבקה, תוך הבטחת הידבקות נאותה. מומלץ לפעול לפי הנחיות היצרן או להתייעץ עם איש מקצוע, מכיוון שמשקל ועובי החומר יכולים להקשות על הטיפול.

האם ממברנת JY-NSB מתאימה לכל האקלים? הוא מתפקד היטב במגוון תנאים, עם עמידות בחום עד 80°C וגמישות בטמפרטורות נמוכות עד -20°C, מה שהופך אותו להתאמה לסביבות חמות וקרות כאחד. עם זאת, תנאים קיצוניים כמו חשיפה ממושכת לטמפרטורות מחוץ לטווח זה עלולים להשפיע על אורך החיים.

כמה זמן מחזיקה קרום JY-NSB מעמד? בתנאים רגילים, הוא יכול להחזיק מעמד 10-15 שנים, תלוי באיכות ההתקנה, גורמים סביבתיים ותחזוקה. גורמים כמו חשיפה לקרינת UV או פעילות שורשים חזקה עלולים לקצר את תוחלת החיים הזו אם לא יטופלו.

האם הממברנה עמידה ביעילות בפני דקירת שורשים? כן, שינוי הפולימר ומעכב השורשים הכימי מספקים עמידות לחדירת שורשים מצמחים ושיחים נפוצים. הוא נבדק לעמידות בפני ניקוב, אך מערכות שורשים אגרסיביות מאוד עשויות לדרוש מחסומים נוספים.

מהו חוזק המתיחה והגמישות של הממברנה? יש לו חוזק מתיחה של כ-800 ניוטון/50 מ"מ וקצב התארכות של לפחות 30%, מה שמאפשר לו להתאים לתנועות קלות על פני השטח מבלי להיסדק.

האם נדרשת תחזוקה עבור ממברנת JY-NSB? נדרשת תחזוקה מינימלית; מומלץ לבצע בדיקות תקופתיות לאיתור נזקים או הצטברות פסולת, במיוחד באזורים עם צמחייה. הוא מציע עמידות בפני עובש וקורוזיה, מה שמפחית את הצורך בתחזוקה תכופה.

איזו אחריות מגיעה עם המוצר? האחריות משתנה בהתאם לספק, אך בדרך כלל מכסה פגמי ייצור למשך 5-10 שנים. יש לבדוק עם המפיץ את התנאים הספציפיים, מכיוון שייתכן שהיא לא תכלול שגיאות התקנה או נזקים סביבתיים.

אודות המפעל שלנו

חברת Shandong Great Ocean Waterproof Technology Co., Ltd. (לשעבר Weifang Juyang New Waterproof Materials Co., Ltd.) ממוקמת בעיר טייטו, ששואוגאנג סיטי, מרכז החומרים העמידים למים הגדול ביותר בסין. נוסדה בשנת 1999, כחברה היי-טק המתמחה בפתרונות אטימה למים, המשלבת מחקר ופיתוח, ייצור ומכירות.

- מִתקָןהמפעל שלנו, המשתרע על פני 26,000 מ"ר, כולל קווי ייצור מתקדמים לממברנות, יריעות וציפויים.

- מוצריםאנו מציעים עשרות פריטים, כולל ממברנות אטימות פולימריות (למשל, פוליאתילן פוליפרופילן, PVC, הסכם זכויות יוצרים (TPO)), אפשרויות הדבקה עצמית, זנים עמידים בפני ניקוב שורשים כמו JY-NSB, לוחות ניקוז, ממברנות אספלט מעובדות, ו ציפויים שונים לאטום למים (פוליאוריטן, על בסיס צמנט, אספלט גומי).

- איכות והסמכותמגובה במומחיות טכנית חזקה, ציוד מתקדם ויכולות בדיקה מלאות. מאושר על ידי רשויות לאומיות, כולל תקן ניהול האיכות של משרד החקלאות, מערכות איכות ISO, איגוד בדיקות האיכות של סין ורישיונות תעשייתיים של שאנדונג.

- טווח הגעה לשוקמוצרים הנמכרים ביותר מ-20 מחוזות סיניים ומיוצאים לחו"ל, בעלי מוניטין של אמינות ושביעות רצון משתמשים.

- ערכיםאנו פועלים ביושרה, פרגמטיזם וחדשנות, תוך שאיפה לשותפויות מנצחות באמצעות מוצרים בעלי ערך גבוה ושירות מעולה.