סרט עמיד למים מגומי בוטיל

סרט איטום מגומי בוטיל עשוי בעיקר מגומי בוטיל עם חומרי עזר נוספים, המעובד בטכניקות מיוחדות לפס איטום שאינו מתקשה ודביק. סרט זה מספק הדבקה חזקה למשטחי חומרים מגוונים, יחד עם עמידות בפני מזג אוויר, עמידות בפני הזדקנות ויכולות איטום. הוא אוטם, בולם רעידות ומגן על אזורים דבוקים ללא ממסים, הצטמקות או פליטות רעילות. בשל אופיו הקבוע שאינו מתקשה, הוא מסתגל היטב להתפשטות תרמית, כיווץ ושינויים מכניים על משטחים. כיצרן בסין, המפעל שלנו מציע מוצר זה במחירים תחרותיים.

מבוא למוצר

סרט איטום מגומי בוטיל הוא חומר איטום דביק המורכב בעיקר מגומי בוטיל, מעורבב עם תוספים ומעובד בטכניקות ייצור סטנדרטיות. הוא נותר ללא ריפוי לאורך זמן, מה שמאפשר לו להסתגל לתנועות פני השטח הנגרמות משינויי טמפרטורה או לחץ מכני מבלי לאבד את האטימות שלו.

סרט זה נדבק היטב למגוון משטחים, כולל מתכות, פלסטיק, עץ ובטון, ומציע עמידות בפני מזג אוויר, חשיפה לקרינת UV והזדקנות. הוא גם מספק אטימות למים, יחד עם ספיגת זעזועים מסוימת ותכונות הגנה מפני לחות וגורמים סביבתיים.

יישומים נפוצים כוללים איטום גגות, חלונות, צינורות, קרוואנים וסירות למניעת דליפות, כמו גם שימוש בבנייה לחיבורים ותיקונים. הוא פועל בטמפרטורות שבין -40°F ל-248°F וזמין ברוחבים ואורכים שונים, לעתים קרובות עם גיבוי נייר אלומיניום לעמידות נוספת בסביבות חיצוניות.

להתקנה, יש לנקות את המשטח לפני מריחת הסרט כדי להבטיח הידבקות נכונה. זוהי אפשרות מעשית הן למשימות איטום "עשה זאת בעצמך" והן למשימות איטום מקצועיות, בהן נדרשת גמישות והידבקות לטווח ארוך.

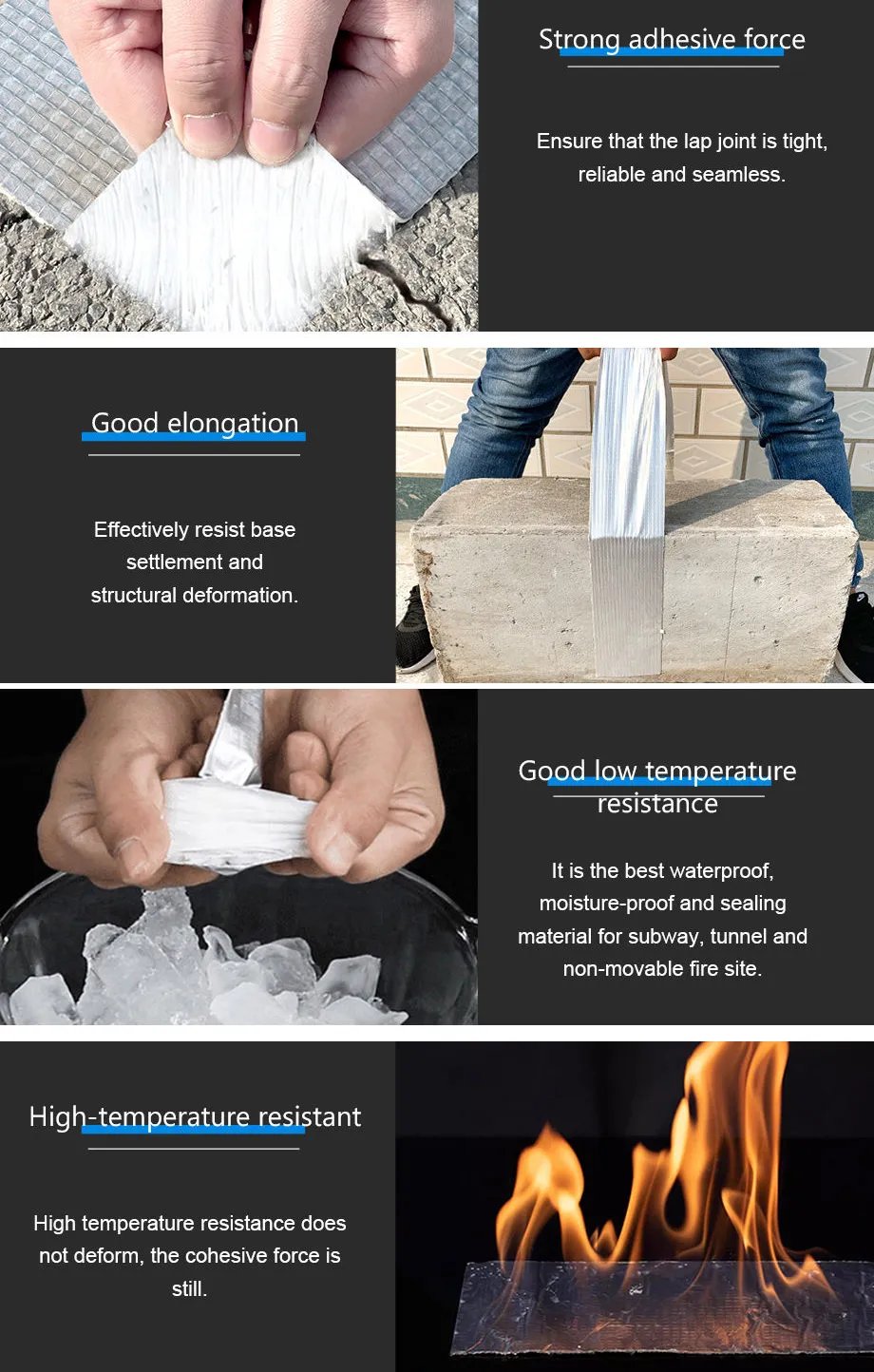

תכונות עיקריות

- נשאר עמיד בפני ריפוי לאורך כל תוחלת החיים שלו, מה שמאפשר לו להישאר גמיש ולהתאים את עצמו לתזוזות פני השטח עקב התפשטות תרמית או שינויים מכניים.

- מספק איטום יעיל למים יחד עם עמידות בפני קורוזיה כימית וחשיפה לקרינת UV, תורם לאורך חיים של מעל 20 שנה בתנאים אופייניים.

- דבק חזק למגוון משטחי חומרים, כגון מתכות, פלסטיק ובטון, ומציע פונקציות איטום, ריסון רעידות והגנה.

- קל ליישום ללא צורך בכלים מיוחדים או זמן ייבוש, מה שהופך אותו מתאים לתיקונים והתקנות מהירות.

יישומים בבנייה

סרט איטום מגומי בוטיל משמש בדרך כלל במגוון תרחישי בנייה למשימות איטום ואיטום. להלן מספר יישומים אופייניים:

- קירוי וגימור: משמש לאיטום חיבורים סביב ארובות, חלונות גג ולוחות גג למניעת דליפות מים. הוא משמש גם ביריעות גגות ולתיקון גגות גומי.

- איטום חלונות ודלתות: משמש ליצירת אטמים אטומים ועמידים למים סביב מסגרות חלונות ודלתות במהלך התקנה או תיקונים.

- תיקוני מרזבים וצנרת: משמש לתיקון סדקים במרזבים ולאיטום צינורות אינסטלציה לטיפול בדליפות.

- מיזוג אוויר ותעלות אוויר: אוטם מפרקי תעלות במערכות חימום, אוורור ומיזוג אוויר כדי למנוע דליפות אוויר.

- איטום יסודות ומרתפים: מיושם על יסודות, מרתפים וקירות כדי לספק הגנה מפני לחות.

- איטום חיבורים ותפרים: אוטם פערים בחומרי בניין כגון לוחות מתכת, סדקי בטון ואביזרי בידוד.

- מבני תשתית של הסיפון: מגן על קורות עץ מפני לחות בבניית דק על ידי יצירת מחסום מתחת ללוחות הדק.

- בנייה וחיפוי מתכת: משמש בגגות וחיפוי מתכת כדי להבטיח חיבורים אטומים למים ושלמות מבנית.

השוואה: סרט אטום למים מגומי בוטיל לעומת סרט אטום למים דביק מאספלט

גם גומי בוטיל וגם סרטי דביקות עצמית לאיטום מים, המבוססים על אספלט (על בסיס ביטומן), משמשים לאיטום ואיטום בבנייה, גגות ותיקונים. יש להם חפיפה מסוימת ביישומים שלהם, אך הם נבדלים בתכונות החומר, בביצועים ובהתאמה לתנאים ספציפיים.

| אַספֶּקט | סרט עמיד למים מגומי בוטיל | סרט דביק עמיד למים לאספלט |

|---|---|---|

| חומר בסיס | גומי בוטיל סינתטי (על בסיס פוליאיזובוטילן) | אספלט שמקורו בנפט (ביטומן), לעתים קרובות עם מודיפיקטורים |

| גמישות ותאימות | נשאר ללא ריפוי וגמיש מאוד לאורך זמן; מסתגל היטב לתנועת פני השטח, התפשטות תרמית וצורות לא סדירות | גמישות ראשונית טובה אך יכולה להפוך שבירה בקור או להתרכך/לזרום בחום גבוה |

| הַדבָּקָה | קשר חזק וארוך טווח למשטחים שונים (מתכת, פלסטיק, בטון, עץ); סיכון נמוך לכתמים או נדידה | דביקות ראשונית אגרסיבית מאוד; מתפקדת היטב על משטחים נקבוביים כמו בטון או אספלט |

| עמידות טמפרטורה | טווח טמפרטורות רחב (בדרך כלל -40°F עד מעל 200°F); יציב הן בקור והן בחום קיצוני ללא נזילה | עלול להתרכך או לדמם בטמפרטורות גבוהות; עלול להיסדק בטמפרטורות נמוכות מאוד |

| עמידות ואורך חיים | בדרך כלל 20+ שנים; עמידות מעולה בפני UV, בליה ועמידות כימית | ביצועים יציבים אך אורך חיים קצר יותר בתנאים חשופים עקב פוטנציאל להידרדרות |

| איטום | חדירות נמוכה לאדי מים; יוצר אטימה אמינה ואטומה | איטום יעיל, במיוחד לתיקוני גגות וסדקים כלליים |

| סביבה ובטיחות | בדרך כלל ללא ממס, ריח נמוך, ידידותי יותר לסביבה | עשוי להיות בעל ריח אספלט; חלק מהפורמולות מכילות ממסים |

| עֲלוּת | גבוה יותר עקב ניסוח גומי סינתטי | בדרך כלל זול יותר וידידותי יותר לתקציב |

| יישומים נפוצים | חיבורי גג, איטום חלונות/דלתות, איטום קרוואנים/סירות, צינורות, תעלות מיזוג אוויר, חשיפה חיצונית ארוכת טווח | תיקוני גגות, איטום מרזבים, סדקים בחניה, איטום יסודות, בנייה כללית |

| מגבלות | עלות גבוהה יותר; ההתקנה עשויה לדרוש משטחים נקיים יותר לצורך הדבקה אופטימלית | פוטנציאל לזרימה בטמפרטורה גבוהה, עמידות מופחתת לקרינת UV ללא גיבוי מגן, כתמים אפשריים |

בפועל, סרט בוטיל נבחר לעתים קרובות עבור יישומים הדורשים גמישות ארוכת טווח ועמידות לתנאים קיצוניים, בעוד שסרט אספלט הוא בחירה מעשית לתיקונים חסכוניים וכבדים בסביבות פחות תובעניות. הבחירה תלויה בדרישות הפרויקט הספציפיות, בחשיפה ובתקציב.

ביקורות לקוחות

מייקל ט., ארצות הברית 4 כוכבים השתמשתי בסרט בוטיל זה כדי לתקן מרזב דולף בבית שלי. ניקיתי את האזור קודם, מרחתי אותו, והוא אטם את הסדק מיד. עברו שישה חודשים של גשם כבד, ואין עוד דליפות. נדבק היטב למתכת, אם כי צריך קצת לחץ כדי לגרום לו להתאים.

שרה ל., קנדה 5 כוכבים יישמתי את זה סביב פתחי האוורור בגג בקרוואן שלי לפני נסיעה ארוכה. זה נשאר גמיש במזג אוויר קר והחזיק מעמד גם בנסיעה בכביש מהיר עם רעידות. לא נכנסו מים במהלך קמפינג בגשם. קל לחתוך ולמרוח, רק לוודא שהמשטח יבש.

דיוויד ר., בריטניה 4 כוכבים השתמשתי בו להברקה סביב חלונות חדשים בפרויקט שיפוץ. הוא נדבק היטב ללבנים ולמסגרות אלומיניום. אחרי חורף גשום, הכל עדיין יבש בפנים. זו לא האפשרות הזולה ביותר, אבל הוא עושה את העבודה בלי צורך בחומרי איטום נוספים.

אמה ק., אוסטרליה 5 כוכבים תיקנתי דליפה קטנה בגג הסככה שלי מפח גלי בעזרת הסרט הזה. הוא מטפל בחום כאן בלי להתרכך או להתקלף. יישמתי אותו לפני יותר משנה, והוא עדיין מחזיק מעמד גם בשמש הקיץ ובסערות. כיסוי רוחב טוב לתפרים גדולים יותר.

תומאס ב., גרמניה 4 כוכבים אטום חיבורים בסככת גינה ממתכת ובכמה צינורות חיצוניים. נדבק היטב למשטחים צבועים לאחר ניקוי. עמד בכפור ובגשם במשך מספר חודשים. הוא עבה מספיק כדי לגשר על פערים קטנים, והסרת הגיבוי הייתה פשוטה.

ליאם ה., ניו זילנד 5 כוכבים תיקנתי סדק באביזר הסיפון של הסירה שלי. נשאר במקומו אפילו בחשיפה למי מלח ותזוזות. השתמשתי בו מתחת למים באופן זמני במקרה חירום, והוא החזיק מעמד עד לתיקון הולם. אמין לשימוש ימי בתנאים רטובים.

אנה ס., יפן 4 כוכבים בשימוש על פלאשינג למרפסת של בניין הדירות שלי. הידבקות טובה לבטון ומתכת. אחרי עונת הטייפון עם רוחות חזקות וגשם, אין בעיות עם כניסת מים. קל לעבוד איתו במזג אוויר לח, פשוט לחץ בחוזקה.

שאלות נפוצות (FAQ)

ש: לאילו משטחים הסרט הזה יכול להיצמד? א: הוא נדבק היטב למשטחים נקיים ויבשים, כולל מתכת (אלומיניום, פלדה), בטון, עץ, פלסטיק, גומי וזכוכית. לקבלת התוצאות הטובות ביותר, יש להסיר לכלוך, שמן או חומר רופף לפני היישום. ההידבקות עשויה להיות מופחתת על משטחים נקבוביים מאוד או מאובקים.

ש: איך אני מורחת את הסרט בצורה נכונה? א: נקו וייבשו את האזור היטב. קלפו את ציפוי ההגנה, לחצו את הסרט בחוזקה על המשטח והחליקו אותו בעזרת רולר או לחץ ידני כדי להסיר בועות אוויר. חפיפו את התפרים ב-5 ס"מ לפחות לאיטום טוב יותר. אין צורך בזמן ייבוש - הוא נאטם באופן מיידי.

ש: באיזה טווח טמפרטורות הוא יכול להתמודד? א: הסרט פועל בדרך כלל בטמפרטורות שבין -40°F (-40°C) ליותר מ-90°C (200°F). הוא נשאר גמיש בתנאים קרים ואינו מתרכך יתר על המידה בחום.

ש: כמה זמן האיטום מחזיק מעמד? א: בתנאים רגילים עם יישום נכון, הוא יכול לספק איטום יעיל למשך 20 שנה או יותר, תלוי בחשיפה לקרינת UV, מזג אוויר ועומס מכני.

ש: האם זה מתאים לשימוש חיצוני? ת: כן, הוא מציע עמידות טובה בפני קרינת UV, מזג אוויר ולחות, מה שהופך אותו מתאים ליישומים חשופים כמו גגות, הבזקים ומרזבים.

ש: האם ניתן לצבוע מעל הסרט הדבק? א: ניתן לצבוע חלק מהגרסאות לאחר היישום, אך יש לבדוק את פרטי המוצר הספציפיים. הידבקות הצבע משתנה, ולעתים קרובות משתמשים בו ללא צביעה לקבלת ביצועים מלאים.

ש: במה זה שונה מסרט עמיד למים על בסיס אספלט? א: סרט בוטיל נשאר גמיש לאורך זמן ועומד בטווחי טמפרטורות רחבים יותר מבלי לזרום בחום או להיסדק בקור. סרט אספלט בדרך כלל זול יותר ונדבק בצורה אגרסיבית למשטחים נקבוביים אך עלול להתכלות מהר יותר באור שמש ישיר.

ש: האם קל להסירו במידת הצורך? א: הוא יוצר קשר חזק וקבוע, כך שהסרה יכולה להיות קשה. השתמשו במרית או באקדח חום כדי לרכך אותו, ולאחר מכן נקו שאריות בעזרת ממס במידת הצורך. הוא מיועד להתקנה לטווח ארוך, לא להסרה תכופה.

ש: כיצד עליי לאחסן את הקלטת? א: יש לשמור את הגלילים במקום קריר ויבש הרחק מאור שמש ישיר. יש לאחסן בטמפרטורת החדר לטיפול מיטבי במהלך היישום.

ש: האם ניתן להשתמש בו מתחת למים או על משטחים רטובים? א: מומלץ ליישם אותו על משטחים יבשים להדבקה אופטימלית. למרות שהוא עמיד למים לאחר המריחה, ההדבקה הראשונית באזורים רטובים עשויה להיות חלשה יותר. במקרה של דליפות חירום, הוא יכול לספק איטום זמני.

אודות המפעל שלנו

חברת Great Ocean Waterproof Technology Co., Ltd. (לשעבר Weifang Great Ocean New Waterproof Materials Co., Ltd.) ממוקמת בעיר טייטו, ששואוגאנג - בסיס ייצור החומרים האיטומים הגדול ביותר בסין. נוסדה בשנת 1999, והיא יצרנית היי-טק המתמחה בתעשיית האיטום המשלבת מחקר, ייצור ומכירות.

המפעל משתרע על שטח של 26,000 מ"ר. לאחר שנים של פיתוח וחדשנות, הוא רכש מספר קווי ייצור ברמות מקומיות מתקדמות עבור סלילים, יריעות ו... אטומים למים. ציפוייםהמוצרים העיקריים כוללים ממברנות אטימות למים מפוליאתילן פוליפרופילן (פוליאסטר), ממברנות אטומות למים מפוליוויניל כלוריד (PVC), ממברנות אטומות למים מפוליאולפין תרמופלסטי (TPO), ממברנות אטימות למים מפוליאתילן כלורי (CPE) ייעודיות לרכבת מהירה, ממברנות אטימות למים דביקות עצמית מפולימר פוליפרופילן, ממברנות אטימות למים מסרט פולימר ריאקטיבי מונח מראש שאינו מבוסס אספלט, ממברנות אטימות למים דביקות ריאקטיביות מפולימר חזקות עם למינציה צולבת, לוחות ניקוז מגנים, ממברנות אטימות למים מאספלט מעובד אלסטומר/פלסטומר, ממברנות אטימות למים דביקות עצמית מבוססות אספלט, ממברנות אטימות למים עמידות בפני ניקוב שורשים מאספלט מעובד פולימר, ממברנות אטימות למים מפולימר מבוסס מתכת עמידות בפני ניקוב שורשים, ממברנות אטימות למים מפולימר פולימרי עמיד בפני ניקוב שורשים מפולימר פולימרי, ממברנות אטימות למים מפוליוויניל כלוריד PVC עמידות בפני ניקוב שורשים. ציפויי פוליאוריטן חד-רכיביים לאיטום מים, ציפויי פוליאוריטן דו-רכיביים עמידים למים, ציפויים אטומים למים מרוכבים מצמנט פולימרי (JS), ציפויי פוליאוריטן עמידים למים על בסיס מים (951), דבק אבקה יבש ייעודי מפוליאתילן-פרופילן (פוליאסטר), ציפויים אטומים בפני מים גבישיים חודרניים על בסיס צמנט, ציפויים אטומים בפני מים מגומי לאספלט בעל התקשות מהירה בהתזה, ציפויים אטומים בפני מים מגומי לאספלט שאינם מתקשים, דבק אטום בפני מים שקוף לקירות חיצוניים, ציפויים אטומים בפני מים נוזליים בעלי גמישות גבוהה בסלילים, סרטי אטימות בפני מים מאספלט דביקים עצמית, סרטי אטימות עצמיים מגומי בוטיל ועוד עשרות סוגים.

לחברה יכולות טכניות חזקות, עם צוות טכנאים מקצועיים, ציוד מתקדם, מכשירי בדיקה מלאים ואיכות יציבה ואמינה המאושרת על ידי מוסדות בדיקה לאומיים מוסמכים. היא קיבלה את התואר "תאימות ניהול איכות מקיף" של משרד החקלאות ועברה הסמכת מערכת אבטחת איכות. בנוסף, היא הוכרה כיחידה של "מוצר מוסמך לאומי לבדיקה" על ידי איגוד פיקוח האיכות של סין, מחזיקה ב"תעודת רישום מוצרי בנייה תעשייתיים", "רישיון ייצור מוצרים תעשייתיים", "הסמכת CE" ועוד במחוז שאנדונג. החברה מכבדת חוזים ושומרת על אמינות, עם מוצרים הנמכרים ביותר מ-20 מחוזות ואזורים בארץ ומיוצאים למדינות ואזורים רבים בחו"ל, וזוכה למשוב חיובי ממשתמשים.

חברת Great Ocean Waterproof Technology Co., Ltd. משתמשת במערכת ניהול תפעולי מודרנית, המונחית על ידי רוח התאגיד של "יושרה, פרגמטיזם, חדשנות" ומטרת "שיתוף מנצח". היא משתפת פעולה עם לקוחות כדי להרחיב את השוק באמצעות יחסי עלות-תמורה גבוהים ושירותים איכותיים, תוך יצירת הישגים חדשים באופן מתמיד.