ממברנת איטום עמידה בפני ניקוב שורש מבוססת אספלט נחושת JY-NTT

ממברנת איטום עמידה בפני ניקוב שורשים מבוססת אספלט נחושת מבית JY-NTT עשויה מאלסטומר תרמופלסטי מסטירן בוטדיאן סטירן (SBS) כמשנה, עם מעכבי שורשים כימיים למניעת צמיחת שורשי צמחים לכיוון שכבת האיטום, בסיס צמיג נחושת מרוכב כחיזוק, וסרט פוליאתילן (PE) כחומר בידוד פני השטח. כיצרנית בסין, Great Ocean Waterproof מייצרת את מוצר היריעה המסולסל הזה במפעל שלנו תוך שימוש בחומרים מבוססים. הוא זמין במחיר שוק סטנדרטי עבור יישומי בנייה.

מבוא למוצר

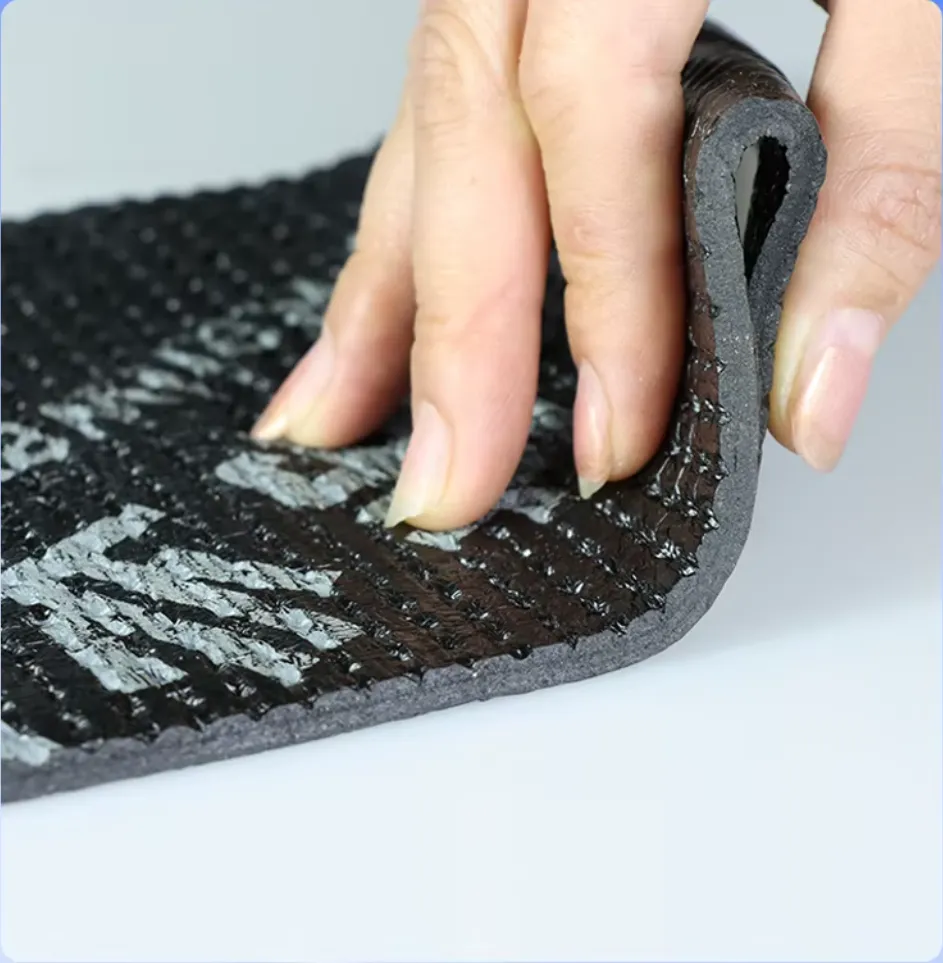

ממברנת איטום JY-NTT, עמידה בפני ניקוב שורשים על בסיס נחושת מאספלט מעובד, היא חומר איטום ייעודי המיועד ליישומים בהם חדירת שורשי צמחים מהווה דאגה, כגון גגות ירוקים, טרסות ויסודות. היא מורכבת מאלסטומר תרמופלסטי של סטירן בוטדיאן סטירן (SBS) כחומר משנה בשכבת האספלט, משולב עם מעכבי שורשים כימיים כדי להגביל את צמיחת השורשים לכיוון שכבת האיטום מבלי לפגוע בהתפתחות הכוללת של הצמח. המבנה כולל בסיס צמיג נחושת מרוכב המשמש כשכבת חיזוק, וסרט פוליאתילן (PE) המונח כחומר בידוד הן על פני השטח והן על פני השטח.

ממברנה זו יוצרת יריעה מסולסלת, המספקת מחסום מפני חדירת מים תוך שמירה על שלמות מבנית תחת לחץ. מפרטים סטנדרטיים כוללים עובי של 4.0 מ"מ, אורך של 10 מטר ורוחב של 1.0 מטר. היא מפגינה עמידות לטמפרטורות גבוהות ונמוכות, מתאימה לאקלים שונים, יחד עם תכונות המתמודדות עם קורוזיה, עובש וחשיפה לפגעי מזג אוויר.

מפרט טכני

ממדים פיזיים

| נֶכֶס | עֵרֶך |

|---|---|

| עוֹבִי | 4.0 מ"מ |

| מֶשֶׁך | 10 מטר |

| רוֹחַב | 1.0 מטר |

| חומר פני השטח | סרט פוליאתילן (PE) |

| חומר תחתון | סרט פוליאתילן (PE) |

| טוֹפֶס | סדין מסולסל |

הרכב החומר

| רְכִיב | תֵאוּר |

|---|---|

| מַתקֵן | סטירן בוטדיאן סטירן (SBS) אלסטומר תרמופלסטי |

| שכבת אספלט | אספלט מעובד עם מעכבי שורשים כימיים |

| שכבת חיזוק | בסיס צמיג נחושת מרוכב |

| חומר בידוד | סרט פוליאתילן (PE) על שני המשטחים |

מדדי ביצועים

| מֶטרִי | ערך/תיאור |

|---|---|

| חוזק מתיחה | ≥ 800 ניוטון/50 מ"מ |

| התארכות בשבירה | ≥ 40% |

| עמידות בטמפרטורה גבוהה | אין זרימה ב-105 מעלות צלזיוס |

| עמידות בטמפרטורה נמוכה | אין סדקים ב-25°C- |

| עמידות לחדירת שורשים | מעכב צמיחת שורשים באמצעות יוני נחושת מבלי להשפיע על התפתחות הצמח הכוללת |

| עמידות בפני ניקוב, שחיקה וקריעה | מסופק על ידי בסיס נחושת מרוכב |

| עמידות בפני קורוזיה ועובש | מעולה, מתאים לחשיפה ארוכת טווח |

| טווח טמפרטורות הפעלה | -25°C עד 105°C |

| נכסים נוספים | מקל על ייצור הנפט במהלך היישום, מפחית את צורכי החימום ופליטות הגזים |

תכונות מוצר

- חיזוק עם בסיס צמיג נחושת מרוכבמשמש כשכבה מבנית העמידה בפני נקבים, שריטות וקרעים, ומגנה מפני נזקים הן מהמשטחים העליונים והן מהמשטחים התחתונים.

- עמידות לחדירת שורשים באמצעות יוני נחושתמעכב את הרקמה המריסטמטית בקצות שורשי הצמח באמצעות פעולת יוני נחושת, ומפנה את השורשים הרחק משכבת האיטום המים מבלי לפגוע בצמיחת הצמח הכוללת, ומבטיח ביצועי איטום לטווח ארוך.

- עמידות בפני קורוזיה ועובשמספק הגנה יעילה מפני קורוזיה והיווצרות עובש בתנאי סביבה שונים.

- חוזק מתיחה והתארכות גבוהיםמציע חוזק מתיחה של לפחות 800 ניוטון/50 מ"מ והתארכות של 40% ומעלה, המאפשר יכולת הסתגלות להתכווצות, עיוות וסדקים של הבסיס.

- סובלנות טמפרטורהשומר על שלמותו מבלי לזרום בטמפרטורות גבוהות עד 105°C או להיסדק בטמפרטורות נמוכות עד -25°C, מתאים לטווח פעולה רחב.

- תהליך ייצור יעילמקל על ייצור שמן במהלך האפייה, מה שעוזר להוריד את טמפרטורות החימום ולהפחית פליטות גזים.

מדד ביצועים

| לֹא. | פָּרִיט | אינדיקטורים טכניים | |

|---|---|---|---|

| 1 | תכולה מסיסה (גרם/מ"ר) ≥ | 4 מ"מ | 2900 |

| 2 | עמידות בחום | פריטי בדיקה | בסיס צמיג לא דליק |

| ℃ | 105 | ||

| ≤ מ"מ | 2 | ||

| תופעה ניסיונית | אין טפטוף או טפטוף | ||

| 3 | גמישות בטמפרטורה נמוכה/℃ | -25 | |

| 4 | אטימות/30 דקות | אין סדקים 0.3 מגה פסקל | |

| 5 | כוח משיכה | כוח מתיחה שיא מקסימלי/(N/50 מ"מ) ≥ | 800 |

| תופעה ניסיונית | במהלך תהליך המתיחה, לא היה סדקים או הפרדה של ציפוי האספלט מבסיס הצמיג במרכז הדגימה. | ||

| 6 | קצב התארכות | התארכות מתיחה שיא מקסימלית / (N / 50 מ"מ) ≥ | 40 |

| 7 | עלייה במסה לאחר טבילה במים % ≤ | PE, S | 1.0 |

| מ | 2.0 | ||

| קצב שימור מתיחה /% ≥ | 90 | ||

| קצב שימור התארכות /% ≥ | 80 | ||

| גמישות בטמפרטורה נמוכה/℃ | -20 | ||

| אין סדקים | |||

| שינוי ממדי /% ≤ | 0.7 | ||

| אובדן מסה /% ≤ | 1.0 | ||

| 8 | הזדקנות תרמית | 1.5 | |

| 9 | חוזק קילוף חיבור / (N/mm) ≥ | 1.0 | |

| 10 | עמידות בפני קורוזיה לעובש | רמה 1 | |

| 11 | עובי ציפוי האספלט על המשטח התחתון של חומר הגליל/מ"מ ≥ | 1.0 | |

| 12 | אקלים מלאכותי מאיץ הזדקנות | הוֹפָעָה | אין החלקה, זרימה או טפטוף |

| קצב שימור מתיחה /% ≥ | 80 | ||

| גמישות בטמפרטורה נמוכה/℃ | -10 אין סדקים |

מקרי יישום של חומרי מחסום שורשים

ממברנות איטום עמידות בפני ניקוב שורשים, כגון אלו עם בסיסי אספלט ונחושת משופרים, משמשות בפרויקטים של בנייה הכוללים צמחייה כדי למנוע נזק לשורשים תוך שמירה על מחסומי מים. להלן דוגמאות שנלקחו ממתקנים מתועדים.

גגות ירוקים למגורים: קומפלקס גרדניה סיסייד, דז'יבנוב, פולין

פיתוח מגורים מרובה בניינים זה כולל חניה תת קרקעית וגגות ירוקים למחצה עם שיחים ועשבים נמוכים. הפרויקט טיפל בדליפות קודמות משכבות ביטומן במערכות דומות באמצעות שימוש בממברנה תרמופלסטית עם ליבת פולימר פעילה שמתנפחת לאיטום נקבים ומשמשת גם כמחסום שורשים. המערכת, שהותקנה בשלבים ומשתרעת על פני 33,000 רגל מרובע, עברה בדיקות גילוי דליפות אלקטרוניות ולא הראתה דליפות לאחר שנה עד שנתיים של פעילות, מה שהפחית את שכבות ההתקנה והעלויות בהשוואה לאפשרויות ביטומניות מסורתיות.

מתקנים ציבוריים: פרויקטים של מחוז קינג, וושינגטון, ארה"ב

מספר מתקנים במחוז קינג שילבו ממברנות ביטומן מעובדות עם אלמנטים נחושת לעמידות בפני שורשים בגגות ירוקים נרחבים. לדוגמה, נמל התעופה הבינלאומי השתמש במערכת דו-שכבתית עם בסיס מעובד ל-APAO ושכבה עליונה עמידה בפני שורשים משובצת בסרט נחושת וחבישת ג'ל לשמירת לחות. המערכת, שהונחה על משטחי בטון עם שכבות ניקוז ו-2.5-3.8 ס"מ של אדמה, נועדה לתמוך בסדומים ועשבים. התוצאות היו מגוונות; בעוד שהממברנה החזיקה מעמד, שרידות הצמחים הייתה נמוכה עקב אדמה רדודה וחוסר השקיה, מה שהוביל לצמיחת עשבים שוטים. ממברנות דומות מועשרות נחושת שימשו במרכז הצדק ובתחנות הרגולציה, שם אדמה עמוקה יותר (10-15 ס"מ) ותחזוקה תמכו בצמיחה טובה יותר של צמחייה, אם כי הדברת עשבים שוטים דרשה מאמץ מתמשך.

מוסד חינוכי: BCIT Green Roof, קולומביה הבריטית, קנדה

במכון הטכנולוגי של קולומביה הבריטית, מערכת גג ירוק בהתאמה אישית כללה ממברנת ביטומן מעובדת דו-שכבתית SBS עם פורמולה ספציפית עמידה בפני שורשים. הממברנה יושמה על גבי גג הגג, ולאחר מכן ניקוז ושכבות אדמה לצמחייה מבוססת סידן. התקנה זו התמקדה בעמידות באקלים לח, כאשר הממברנה מספקת הגנה מפני חדירת שורשים וחשיפה מתמדת ללחות.

דיור בר-קיימא: פרויקט גרנד דיזיין, ווינדרמיר, בריטניה

גג ירוק כיפתי בבית בר-קיימא השתמש במערכת נוזלית היוצרת קרום חלק וגמיש העמיד בפני חדירת שורשים. היישום כיסה משטחים מעוקלים, תוך שילוב עם ניקוז ואדמה לגידול דשא ופרחי בר. גמישות הממברנה התאימה לתנועות מבניות, ותרמה למטרות הסביבתיות של הפרויקט ללא דיווחים על כשלים באיטום.

מקרים אלה ממחישים שימושים אופייניים בגגות ירוקים עבור מבני מגורים, ציבור ומוסדות, שבהם ממברנות עם חיזוקי נחושת מסייעות בניהול סיכוני שורשים באזורים צמחיים.

עיצוב ירוק גגות

תכנון גגות ירוקים כרוך ביצירת שכבות צמחייה על גגות בניינים כדי לתמוך ביתרונות סביבתיים כמו ניהול מי סערה והפחתת חום עירוני. מערכות אלו כוללות בדרך כלל תמיכה מבנית, איטום, ניקוז, מחסומי שורשים, מצע גידול וצמחייה. העיצובים משתנים לפי סוג: גידול נרחב (קל משקל, דורש תחזוקה מועטה עם אדמה רדודה לסדומים ועשבים), גידול אינטנסיבי (כבד יותר, דמוי גן עם אדמה עמוקה יותר לשיחים ועצים), או גידולים היברידיים חצי אינטנסיביים.

עקרונות עיצוב מרכזיים

- קיבולת עומסמבני גג חייבים להתמודד עם משקל נוסף מאדמה, צמחים, מים ושלג. מערכות נרחבות מוסיפות 15-50 ק"ג/מ"ר, בעוד שמערכות אינטנסיביות יכולות לעלות על 200 ק"ג/מ"ר. יש להתייעץ עם מהנדסי מבנים כדי להעריך עומסים חיים ונשארים, תוך הקפדה על עמידה בתקנים המקומיים.

- שיפוע וניקוזיש להגביל את השיפועים לפחות מ-40 מעלות כדי למנוע סחף; יש לשאוף לשיפוע מינימלי של 1:60 לזרימת המים. יש לכלול שכבות ניקוז עם מסננים כדי למנוע סתימה, ופתחי ניקוז המטפלים בגלישה תוך שעה לאחר גשם כבד.

- איטום ועמידות לשורשיםהשתמשו ביריעות עמידות כמו אספלט מעובד עם עמידות בפני ניקוב שורשים, כגון ממברנת איטום עמידה בפני ניקוב שורשים JY-NTT מבית Great Ocean Waterproof על בסיס נחושת אספלט מעובד מבית Great Ocean Waterproof, המשלבת בסיסי נחושת ומעכבי כימיקלים להגנה יעילה על שורשים במערכות גגות ירוקים. אפשרויות נוספות של Great Ocean כוללות את ממברנת האיטום הפולימרית JY-NHP עמידה בפני ניקוב שורשים ואת ממברנת האיטום הפולימרית JY-NSB עמידה בפני ניקוב שורשים אספלט מעובד מעובד מבית Great Ocean, המתאימה ליישומי גגות בהם יש צמחייה. השכבות כוללות לרוב בידוד, מחסום שורשים והגנה מפני חדירה. בתקנים סיניים, מדובר בשכבת איטום עמידה בפני ניקוב על גבי איטום סטנדרטי. מוצרים נוספים כמו ממברנת איטום EPDM אוֹ ממברנת איטום HDPE מ-Great Ocean יכול לספק תמיכה בסיסית באיטום.

- צמחייה ומצעבחרו צמחים המתאימים לאקלים המקומי - מינים עמידים לבצורת לגגות נרחבים. על המצעים להיות קלים, עשירים בחומרים מזינים ובעלי ניקוז טוב, בעומק של 4-20 ס"מ לגידול נרחב ומעל 20 ס"מ לגידול אינטנסיבי. שלבו השקיה במידת הצורך לצורך ההתבססות. לאיטום משופר מתחת למצעים, שקלו ציפויים כמו Great Ocean. JY-951 ציפוי עמיד למים פוליאוריטן או רכיבים כפולים של JY-DPU ציפוי פוליאוריטן עמיד למים.

- בטיחות וגישה: תנו עדיפות להגנה על הקצוות, עמידות בפני רוחות ונתיבים לתחזוקה. עבור גגות ציבוריים או בסגנון גן, כללו מעקות ונקודות גישה לציוד.

שלבי יישום

- הערכת אתר: יש להעריך את מצב הגג, כושר נשיאת העומס וגורמים סביבתיים כמו חשיפה לשמש ורוח.

- שכבות: התחילו בהכנת הדק, הוסיפו בידוד ואיטום (למשל, ממברנת איטום עמידה בפני ניקוב שורשים מבוססת אספלט נחושת מבית Great Ocean Waterproof מבית JY-NTT להגנה על שורשים, או חלופות כמו JY-APP ממברנת איטום ביטומן שונה וממברנת איטום ביטומן מעובדת JY-SBS לצורכי גגות כלליים), לאחר מכן ניקוז, בד סינון, מצע וצמחים.

- התקנה: השתמשו במערכות מודולריות ליעילות על גגות שטוחים; ודאו שהתפרים אטומים כדי למנוע דליפות. אפשרויות נוזליות כמו ציפוי איטום ביטומני מעובד פולימרי JY-LRT של Great Ocean יכולות להציע יישום גמיש עבור משטחים מורכבים.

- תחזוקה: יש לתכנן עישוב, השקיה בתקופות יבשות ובדיקות שנתיות לבדיקת שלמות הממברנה.

גגות ירוקים תורמים ליעילות אנרגטית על ידי שיפור הבידוד והפחתת נגר עירוני, אך דורשים תכנון מראש כדי להתמודד עם עלויות וכדאיות לטווח ארוך.

ביקורות לקוחות

ג'ון מארצות הברית (התקנת גגות ירוקים) השתמשתי בממברנה הזו בפרויקט גינת גג בשיקגו. היא טיפלה בצמיחת שורשים של צמחי סדום ללא בעיות חדירה בשתי העונות הראשונות. החומר היה קל להתקנה עם כלים סטנדרטיים, והוא החזיק מעמד גם בגשמים עזים. עד כה לא היו דליפות, מה שעמד בציפיות שלי לשכבת איטום בסיסית.

אנה מגרמניה (איטום טרסות) יישמתי את זה במרפסת בברלין, שם יש לנו אדניות עם שיחים. נראה שבסיס הנחושת מרתיע שורשים ביעילות, מכיוון שלא ראינו נזק לאחר שנה. הוא הסתגל לשינויי טמפרטורה מקפיאה בחורף לחום הקיץ מבלי להיסדק. ההתקנה דרשה איטום זהיר בקצוות, אך בסך הכל, הוא ביצע כמתואר.

לי ווי מסין (הגנה על יסודות מבנים) התקנו אותו מתחת לאזור נוף בשנגחאי. עמידות השורשים מנעה משורשי עצים להגיע לשכבת היסוד. הוא עמד בתנאי לחות ובהצפות מדי פעם ללא הצטברות עובש. גודל הגליל היה נוח לאתר שלנו, אם כי היינו זקוקים לדבק נוסף בכמה מקומות.

שרה מאוסטרליה (קירוי מסחרי) נעשה בו שימוש על גג שטוח בסידני עם עשבים מקומיים. הממברנה סיפקה עמידות איתנה בפני ניקובים ושפשופים במהלך ההתקנה. היא עמדה בטמפרטורות גבוהות מבלי להתרכך, ולאחר שישה חודשים, האיטום נותר שלם. התאים לצרכים שלנו לאופציה עמידה במזג אוויר משתנה.

קרלוס מברזיל (בטנת ארגזי אדניות) ריפדתי כמה אדניות גדולות בסאו פאולו בחומר הזה. המעכבים הכימיים סייעו לשלוט בהתפשטות השורשים, תוך שמירה על המבנה יבש. הוא הראה חוזק מתיחה טוב בעת הסתגלות לשינויים בקרקע. לא היו בעיות משמעותיות לאחר השימוש הראשוני, אם כי ניטור קורוזיה ארוכת טווח יהיה המפתח באקלים הטרופי שלנו.

שאלות נפוצות

אילו חומרים משמשים בממברנת איטום עמידה בפני ניקוב שורשים מבית JY-NTT, בעלת בסיס נחושת אספלט שונה? הממברנה מורכבת מאלסטומר תרמופלסטי מסוג סטירן בוטדיאן סטירן (SBS) כמקדם בשכבת האספלט, בסיס צמיג נחושת מרוכב לחיזוק, וסרט פוליאתילן (PE) כחומר בידוד על שני המשטחים. היא כוללת מעכבי שורשים כימיים למניעת חדירת שורשים.

כיצד פועלת עמידות לדקירת שורשים? בסיס הנחושת המרוכב משחרר יוני נחושת אשר מעכבים את צמיחת הרקמה המריסטמטית בקצות שורשי הצמח, ומפנים את השורשים הרחק מהשכבה העמידה למים מבלי לפגוע בצמיחת הצמח הכוללת. זה מסייע בשמירה על תפקוד האיטום של הממברנה לאורך זמן.

מהם אתגרי ההתקנה הנפוצים? ייתכן שההתקנה תדרוש משטחים ישרים ואיטום נאות בקצוות כדי למנוע פערים. הוא מיושם כיריעת גמר, לרוב באמצעות חום או דבקים, ויש צורך בזהירות כדי לטפל בעובי של 4.0 מ"מ ללא קרעים. בסיסים לא אחידים או חפיפות לא נכונות עלולים להוביל לבעיות.

האם הממברנה עמידה בפני שינויי טמפרטורה ומזג אוויר? הוא עומד בטמפרטורות מ-25°C- עד 105°C מבלי להיסדק או לזרום, ומציע עמידות בפני קורוזיה ועובש. עם זאת, תנאים קיצוניים עשויים לדרוש שכבות הגנה נוספות.

היכן ניתן להשתמש בממברנה הזו? הוא מתאים לגגות ירוקים, טרסות, יסודות ואזורים עם צמחייה כמו אדניות או מבנים מעוצבים. הוא מיועד ליישומים בהם חדירת שורשים מהווה סיכון, כגון במערכות גגות או איטום.

כמה עמיד המוצר ואיזו תחזוקה נדרשת? עם התקנה נכונה, הוא מספק איטום לטווח ארוך, אך מומלץ לבצע בדיקות סדירות לאיתור נזקים או פעילות שורשים. גורמים כמו חומציות הקרקע או דשנים יכולים להשפיע על אורך החיים, לכן מומלץ לעקוב אחר תאימות כימית.

האם זה ידידותי לסביבה? תהליך הייצור מפחית את טמפרטורות החימום ואת פליטות הגזים במהלך היישום. עיכוב השורשים אינו פוגע בגדילת הצמח באופן כללי, אך על המשתמשים לבדוק את התקנות המקומיות לגבי מעכבים כימיים.

מהי האחריות או אורך החיים הצפוי? האחריות משתנה בהתאם לספק, ולעתים קרובות מכסה פגמי חומר למשך מספר שנים, אך תוחלת החיים תלויה בהתקנה ובגורמים סביבתיים. יש להתייעץ עם היצרן לקבלת פרטים ספציפיים.

איך זה משתווה לממברנות איטום אחרות? בהשוואה לאפשרויות ביטומן או פולימר סטנדרטיות, הוא מוסיף עמידות לשורשים באמצעות נחושת, מה שהופך אותו מתאים יותר לאזורים צמחוניים. הוא עשוי להיות עבה ומיוחד יותר, אולי בעלות גבוהה יותר, אך מציע הגנה טובה יותר מפני ניקוב.

אודות שאנדונג Great Ocean Waterproof טכנולוגיה בע"מ

חברת Shandong Great Ocean Waterproof Technology Co., Ltd. (לשעבר Weifang Juyang New Waterproof Materials Co., Ltd.), הממוקמת בעיר טייטו, בעיר שוגואנג - בסיס החומרים האיטום הגדול ביותר בסין - נוסדה בשנת 1999. אנו יצרנית מתמחה המשלבת מחקר, ייצור ומכירה של חומרי איטום.

המתקן שלנו, המשתרע על פני 26,000 מ"ר, מפעיל קווי ייצור מתקדמים לממברנות, יריעות ו... ציפוייםאנו מייצרים מגוון רחב של מוצרים, כולל ממברנות איטום פולימריות (פוליאתילן פוליפרופילן, PVC, הסכם זכויות יוצרים (TPO), CPE), ממברנות דביקות עצמיות, ממברנות ביטומן מעובד, ממברנות עמידות בפני ניקוב שורשים (כגון סדרת JY-NTT), לוחות ניקוז, ציפויי פוליאוריטן ומלט פולימרי, ציפויי אספלט מגומי, ומגוון סרטים ודבקים עמידים למים.

עם מומחיות טכנית חזקה, ציוד מודרני ובדיקות איכות מקיפות, המוצרים שלנו עומדים בתקנים לאומיים וזכו במספר הסמכות, כולל הסמכת מערכת ניהול איכות ISO ורישיונות למוצרים תעשייתיים.

אנו מחויבים ליושרה, פרגמטיזם וחדשנות, ומספקים פתרונות אמינים וחסכוניים ללקוחות ביותר מ-20 מחוזות ברחבי סין ובמספר שווקים בינלאומיים.