JY-CCW Sementsbundin gegndræp kristallað vatnsheld húðun Akrýlsýru vatnsheld húðun

Þessi vara er stíft vatnsheldandi duftefni sem er búið til úr sérstöku sementi, kvarssandi og öðrum úrvals innihaldsefnum, blandað saman við fjölvirk efni. Bætið einfaldlega vatni út í til að búa til slétta leðju og berið hana síðan á yfirborð steypuvirkja úr sementssteinum. Eftir herðingu myndar það stíft, límandi lag á steypuyfirborðinu - á meðan virku efnin smjúga djúpt inn í steypuna með gegndræpum vatnsberum. Þessi efni hvata myndun óleysanlegra kristalla með steypusílíkötum, fylla háræðarholur og örsprungur til að þétta steypuna, veita framúrskarandi ógegndræpi og áreiðanlega vatnshelda vörn.

Kynning á vöru

Vörueiginleikar JY-CCW sementsbundinnar gegndræprar kristallaðrar vatnsheldrar húðunar

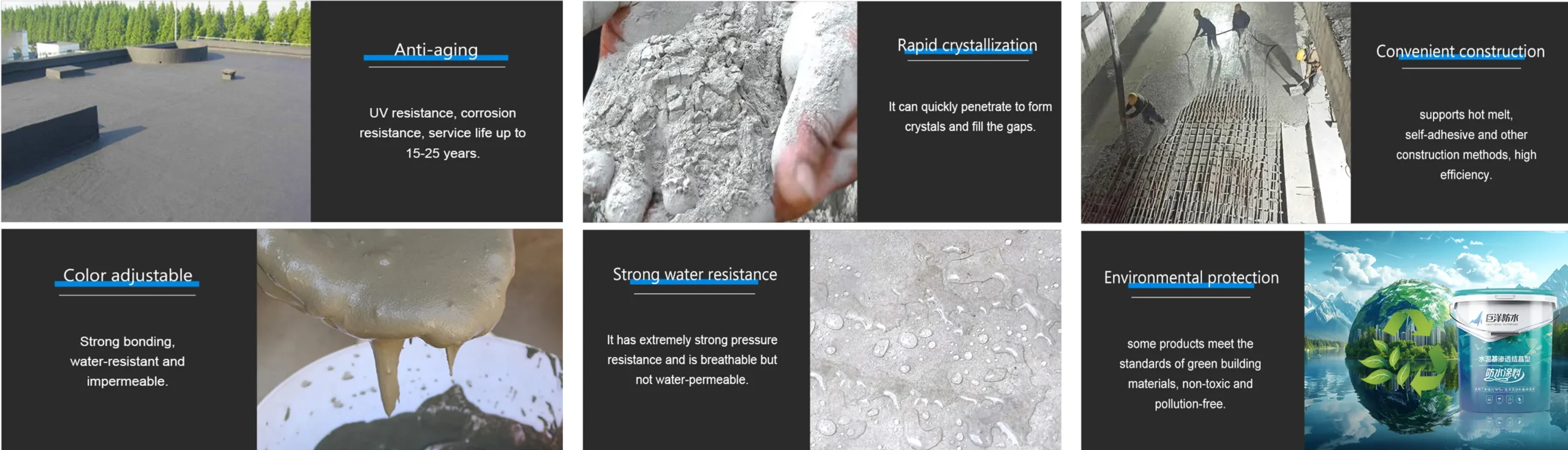

- Mjög sterk skarpskyggni: Getur smogið meira en 5 cm inn í steypuflötið og tryggir djúpa og algera vatnshelda vörn.

- Framúrskarandi árangur gegn leka: Þolir langtíma vatnsþrýsting yfir 120 metra og kemur í veg fyrir að vatn síist inn.

- Óskert vatnsheldni þegar húðun er skemmd: Vatnsheldni helst óbreytt jafnvel þótt húðunin sjálf skemmist, sem kemur í veg fyrir að vatnsheldni bili algjörlega.

- Mikil viðnám gegn skaðlegum efnafræðilegum rofi: Verndar steypu gegn tæringu af völdum skaðlegra efna, sem bætir verulega endingu og líftíma steypumannvirkja.

- Grænt og umhverfisvænt: Eiturefnalaust, skaðlaust og mengunarlaust, uppfyllir umhverfisverndarstaðla. Það er öruggt til notkunar í drykkjarvatnsverkefnum (t.d. vatnstönkum, leiðslum).

- Sjálfvirk sprunguviðgerð: Þéttir hratt örsprungur sem eru minni en 0,4 mm, dregur úr viðhaldsþörf og viðheldur langtíma vatnsheldni.

- Langvarandi vatnsheld áhrif: Veitir endingargóða vatnshelda vörn með stöðugri virkni, jafnvel við langtímanotkun.

- Auka ógegndræpi og sjálfsgræðandi getu: Hefur aukalega eiginleika til að koma í veg fyrir leka til að takast á við hugsanlegar breytingar á vatnsþrýstingi; sjálfgræðandi eiginleikar auka enn frekar áreiðanleika vatnsheldni.

- Ryðvörn, öldrunarþol og stálstöngvernd: Verndar gegn öldrun af völdum umhverfisþátta (t.d. sólarljóss, hitabreytinga) og tæringu; verndar á áhrifaríkan hátt innri stálstangir gegn ryði og varðveitir heilleika steinsteypubygginga.

- Auðveld smíði: Einfalt umsóknarferli, sem krefst ekki flókins búnaðar eða faglegrar færni, sem dregur úr byggingarerfiðleikum og styttir byggingartíma.

Varúðarráðstafanir

- Forðist framkvæmdir í rigningu, þoku, vindi eða sandstormum.

- Notið hreint vatn til að blanda og herða.

- Tryggið að undirlagið sé traust og hreint, laust við ryk, olíu eða laust efni.

- Gerið við sprungur, göt og galla áður en efnið er borið á.

- Þéttið samskeyti pípa með V-rifum og klemmum.

- Haldið réttri þykkt lagsins; forðist að ofblanda eða bæta við vatni.

- Bíðið í 36 klukkustundir áður en fyllt er aftur; verjið húðunina fyrir vatni í 7 daga.

Árangursvísitala

| Nei. | Vara | Árangursvísitala | ||

|---|---|---|---|---|

| Ég | II. | |||

| 1 | Stöðugleiki | Hæfur | ||

| 2 | Stillingartími | Stilltu tíma mín. ≥ | 20 | |

| Lokatími klst ≤ | 24 | |||

| 3 | Sveigjanleiki MPa ≥ | 7 dagar | 2.80 | |

| 28 dagar | 3.50 | |||

| 4 | Þjöppunarstyrkur MPa ≥ | 7 dagar | 12.0 | |

| 28 dagar | 18.0 | |||

| 5 | Sterk viðloðun á rakt undirlag a/MPa ≥ | 1.0 | ||

| 6 | Þrýstingur gegn leka (28d) MPa ≥ | 0.8 | 1.2 | |

| 7 | Annar þrýstingur gegn leka (56d) MPa ≥ | 0.6 | 0.8 | |

| 8 | Osmósuþrýstingshlutfall (28d) % | 200 | 500 | |

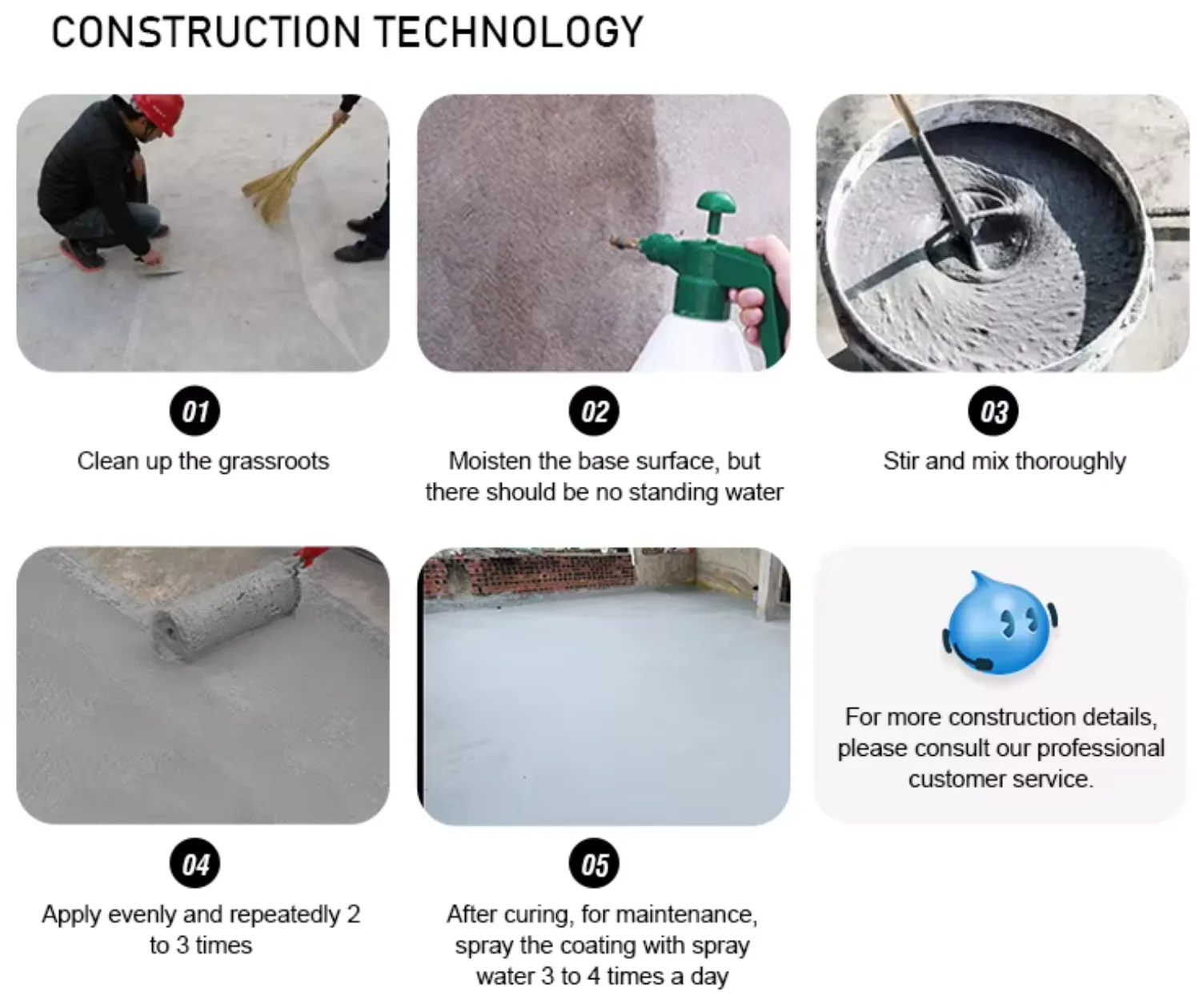

Byggingaraðferð

Burstaaðferð (slurry)

Grunnmeðferð:Hreinsið botninn af leðju, basa, ryki, olíu; gerið yfirborðið hrjúft; skolið með háþrýstivatni.

Blautur grunnur:Vökvið botninn alveg; haldið rökum, ekkert kyrrstætt vatn.

Blöndun

- Hlutfall: duft : vatn = 1 : (0,35–0,4)

- Bætið fyrst vatni út í, síðan dufti; hrærið jafnt.

- Nota innan 20 mín.; ekkert vatn bætt við aftur.

Umsókn

- Burstaðu jafnt með stífum bursta.

- Næsta lag eftir að yfirborðið verður hvítt.

- Ef meira en 12 klst., vætið aftur áður en málning er borin á.

- Skammtar: 1,4–1,7 kg/m²

- Þykkt: 1,0 mm (±0,05 mm)

Þurrdreifingaraðferð

- Dreifing 1,5 kg/m² á hálfherttri steinsteypu.

- Þrýstið inn með trésleif + pússvél; kalendarið yfirborðið.

Herðing

- Geymið rakt í ≥72 klst. (7 dagar tilvalið).

- Sprautið vatni eða hyljið með rökum klút.

- Verjið gegn rigningu; ekki nota sýruhreinsiefni.

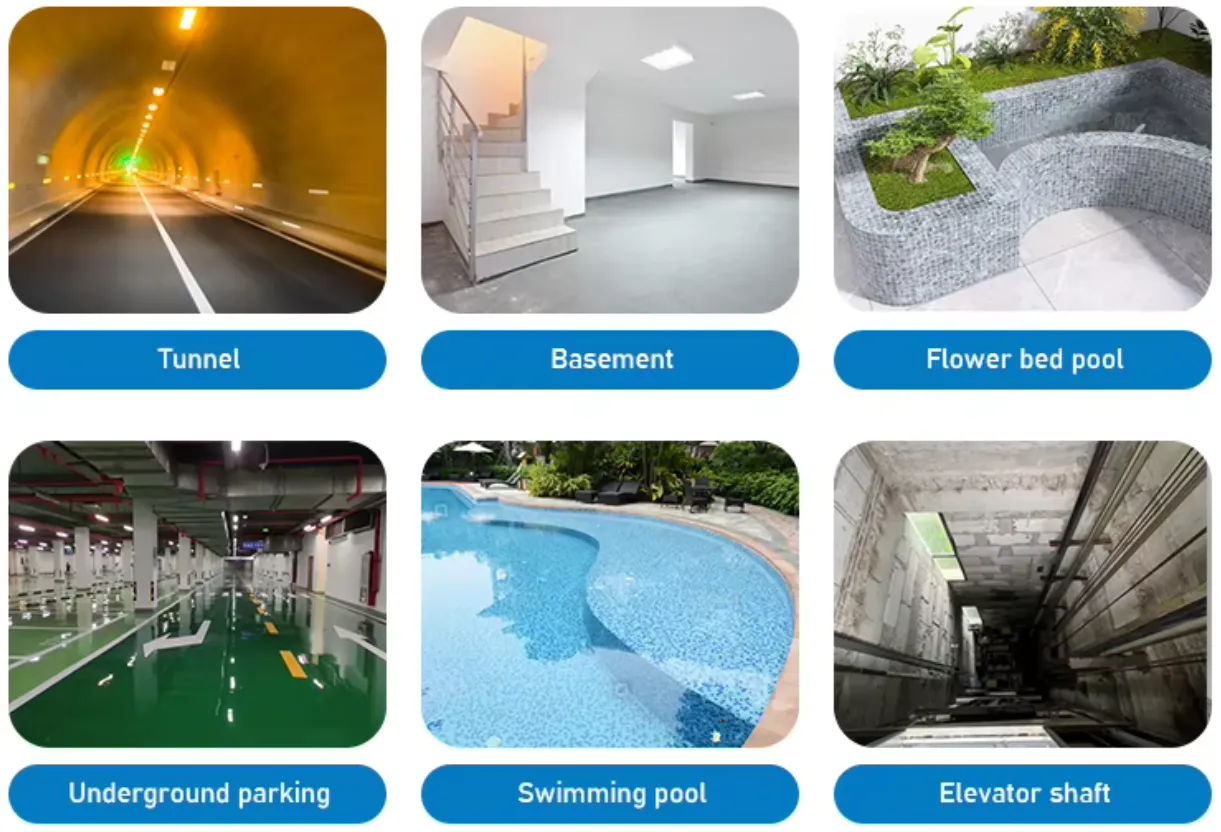

Umsókn

Lýsing á smíði

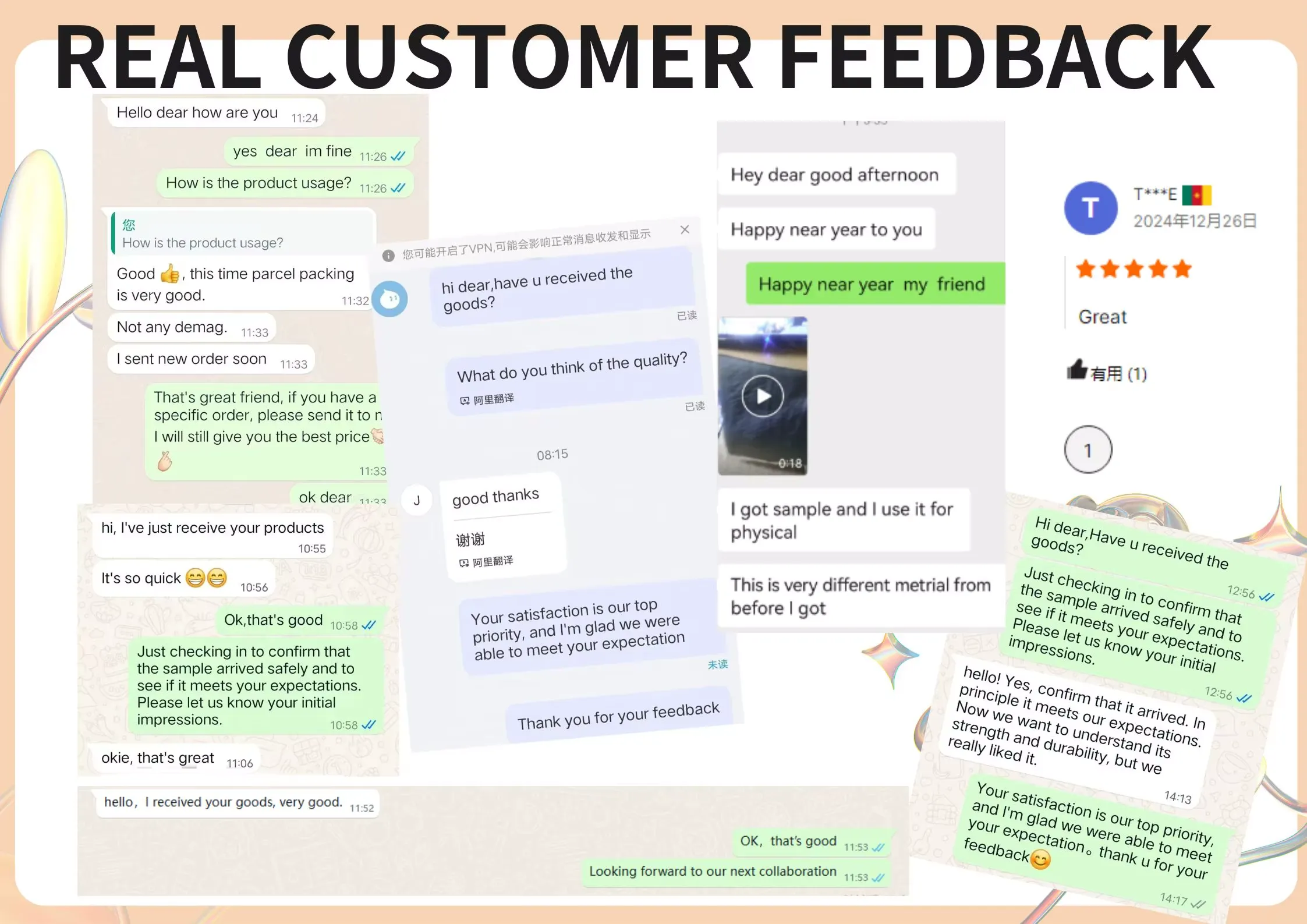

Umsagnir viðskiptavina

John D., Bandaríkin Ég hef notað JY-CCW sementsbundið gegndræpt kristallað vatnsheld húðun í kjallaraviðgerðum. Það blandaðist auðveldlega við vatn og var vel borið á steypta veggina. Eftir nokkra mánuði þoldi það vel minniháttar vatnsleka frá mikilli rigningu og ég tók ekki eftir neinu ryði á innfelldu járnjárni. Innsiglið virðist gott en það krefst vandlegrar undirbúnings yfirborðsins til að forðast ójafna þekju. Í heildina er þetta áreiðanlegur kostur fyrir vatnsheldingu undir jarðvegi.

Anna K., Þýskalandi Sem byggingarverkfræðingur bar ég þessa vatnsheldu akrýlsýruhúð á viðgerðarverkefni í göngum. Sjálfgræðandi eiginleikarnir virkuðu eins og lýst er fyrir litlar sprungur undir 0,4 mm, sem kom í veg fyrir frekari vatnsinnstreymi með tímanum. Það er öldrunarþolið í rökum aðstæðum og tæringarvörnin er kostur fyrir langtíma endingu. Ásetningin var einföld, þó að herðing þurfi stöðugan raka til að ná sem bestum árangri. Það stóðst prófin okkar á fullnægjandi hátt.

Rajesh P., Indlandi Við notuðum JY-CCW á vatnsgeymslutanki í dreifbýli. Umhverfisþátturinn er aðlaðandi þar sem hann er eiturefnalaus og hentar vel fyrir drykkjarvatnsverkefni — enginn lykt eða skaðlegir leifar. Hann veitti góða ógegndræpi gegn leka í monsúnrigningu og kristallarnir mynduðust á áhrifaríkan hátt til að innsigla svitaholur. Hins vegar þarf nákvæma mælingu á skammtinum til að forðast sóun. Þetta er hagnýtur kostur fyrir innviði í röku loftslagi.

Sophie L., Ástralía Ég setti þessa gegndræpu kristallaða sementsblöndu á steinsteypta skel sundlaugarinnar okkar. Hún féll vel að undirlaginu og bauð upp á góða þol gegn efnaáhrifum frá sundlaugarmeðferðum. Vatnsheldnin hélt sér á rigningartímabilinu, án sýnilegra sprungna eða flögnunar eftir sex mánuði. Auðvelt að vinna með hana, en hún harðnar hratt, svo þú þarft að skipuleggja skammtana. Ég er ánægður með útkomuna fyrir afþreyingarnotkun.

Li Wei, Kína Í uppfærslu á skólphreinsistöð var JY-CCW akrýlsýru vatnsheld húðun notuð á tanka og pípur. Hún sýndi góðan þrýsting gegn leka og varði gegn tæringu frá skólpi. Stífleiki efnisins hjálpaði til við að viðhalda burðarþoli og það þurfti ekki þungan búnað til notkunar. Athugið: hún virkar betur á rökum fleti, svo tímasetning er lykilatriði. Hún er hagnýt fyrir iðnaðarumhverfi.

María G., Brasilía Fyrir brúargrunnsverkefni á flóðahættulegu svæði veitti þessi húðun auka ógegndræpi sem hjálpaði til við að viðhalda miklu vatnsþrýstingi. Kristallarnir fylltu örsprungur á áhrifaríkan hátt með tímanum og drógu úr viðhaldsþörf. Hún er mengunarlaus, sem er í samræmi við umhverfisreglur okkar. Blöndun og penslun var einföld, þó að full hörðnun tæki ráðlagða 72 klukkustundir. Traust vara fyrir byggingarverkfræði.

Um verksmiðju okkar

Great Ocean Waterproof Technology Co., Ltd. (áður Weifang Great Ocean New Waterproof Materials Co., Ltd.) er staðsett á strategískum stað í Taitou Town Government Resident í Shouguang borg — hjarta stærstu framleiðslustöðvar Kína fyrir vatnsheld efni. Fyrirtækið var stofnað árið 1999 og er hátæknifyrirtæki sem sérhæfir sig í samþættingu vísindarannsókna, framleiðslu og sölu innan vatnsheldingariðnaðarins.

Verksmiðja okkar spannar glæsilega 26.000 fermetra og er, í gegnum ára nýsköpun og þróun, búin fjölmörgum nýjustu framleiðslulínum fyrir rúlluplötur, plötuefni og húðanir. Við framleiðum með stolti fjölbreytt úrval af hágæða vörum, þar á meðal JY-CCW sementsbundið gegndræpt kristallað vatnsheld húðun og akrýlsýru vatnsheld húðun, ásamt tugum annarra lausna eins og pólýetýlen pólýprópýlen (pólýester) fjölliða vatnsheld himna. PVC vatnsheldandi himnur, TPO vatnsheldandi himnur, klóruð pólýetýlen (CPE) vatnsheldandi himnur fyrir hraðlestar, sjálflímandi vatnsheldandi himnur úr pólýmerpólýprópýleni, sjálflímandi vatnsheldandi himnur úr pólýmerpólýprópýleni sem ekki eru malbikshvarfgjarnar, sterkar þverlagaðar vatnsheldandi himnur úr pólýmerpólýmerpólýprópýleni með hvarfgjörnum límingum, verndandi frárennslisplötur, vatnsheldandi himnur úr SBS/APP breyttri malbiki, sjálflímandi vatnsheldandi himnur úr malbiki, vatnsheldandi himnur úr pólýmerpólýmerpólýmerpólýprópýleni sem eru ónæmar fyrir götum, vatnsheldandi himnur úr málmi og pólýmerpólýperýleni sem eru ónæmar fyrir götum, rótarþolnar vatnsheldandi himnur úr pólýetýlenpólýprópýleni (pólýester), rótarþolnar vatnsheldandi himnur úr PVC, vatnsheldandi húðun úr einþátta pólýúretan, vatnsheldandi húðun úr tvíþátta pólýúretan, vatnsheldandi húðun úr pólýmersementi (JS) samsettum pólýmersementi. Vatnsleysanlegar (951) pólýúretan vatnsheldar húðanir, sérhæfð þurrduftlím fyrir pólýetýlen pólýprópýlen (pólýester), úðabrúsaðar hraðharðnandi vatnsheldar húðanir fyrir gúmmímalbik, vatnsheldar húðanir fyrir gúmmímalbik sem ekki harðnar, gegnsætt vatnsheld lím fyrir útveggi, mjög teygjanleg vatnsheld húðun með fljótandi himnu, sjálflímandi vatnsheldar límbönd fyrir malbik og sjálflímandi límbönd úr bútýlgúmmíi.

Með stuðningi öflugs tækniteymis sérfræðinga, háþróaðs búnaðar og alhliða prófunartækja tryggjum við stöðuga og áreiðanlega vörugæði sem eru vottuð af viðurkenndum innlendum skoðunarstofnunum. Meðal viðurkenninga okkar eru titillinn „Comprehensive Quality Management Compliance“ frá landbúnaðarráðuneytinu, vottun ISO gæðatryggingarkerfisins, viðurkenning sem „Landsvísu viðurkennd prófuð og viðurkennd vara“ frá kínverska gæðaskoðunarfélaginu, „Industrial Construction Product Registration Certificate“ í Shandong héraði og „Framleiðsluleyfi fyrir iðnaðarvörur“.