JY-951 Waterborne Polyurethane Waterproof Coating

Product Overview

| Farge | White | Type | Single-component | Tetthet | 1,3–1,4 kg/l |

| Fysisk tilstand | Flytende | Spesifikasjoner | 20 kg/fat | ||

Performance & Product Features

- Eco-friendly & user-friendly: It’s a single-component, water-based lotion product (free of organic solvents) that’s non-toxic, odorless, and color-adjustable—qualifying as a green environmental protection material. Its easy-to-operate attribute aligns with the accessible usability outlined in resources like eelhoe polyurethane waterproof coating instructions.

- Adaptable & convenient construction: It can be applied on damp substrates with high bonding strength; as a cold-construction product, it’s ready to use directly. Its liquid, room-temperature application (seamless) is especially ideal for complex-shaped sites or flame-prohibited areas, marking it a practical multi purpose polyurethane waterproof coating.

- Superior coating performance: Once cured, it forms an integrated seamless rubber layer with high elongation and tensile strength (excellent waterproof effect). The coating also has high strength (adapts well to substrate shrinkage/cracking) and reliable low-temperature bending performance (no cracks at -10°C)—matching the durability of products like firelye polyurethane waterproof coating.

- Long-lasting & versatile applicability: It has a high solid content, excellent physical-mechanical properties, and strong water/weather/aging resistance (stable under UV, heat, and oxidation for a long service life). Suitable for exposed waterproofing, it performs best in bathroom, pool, wall waterproofing, and repair projects.

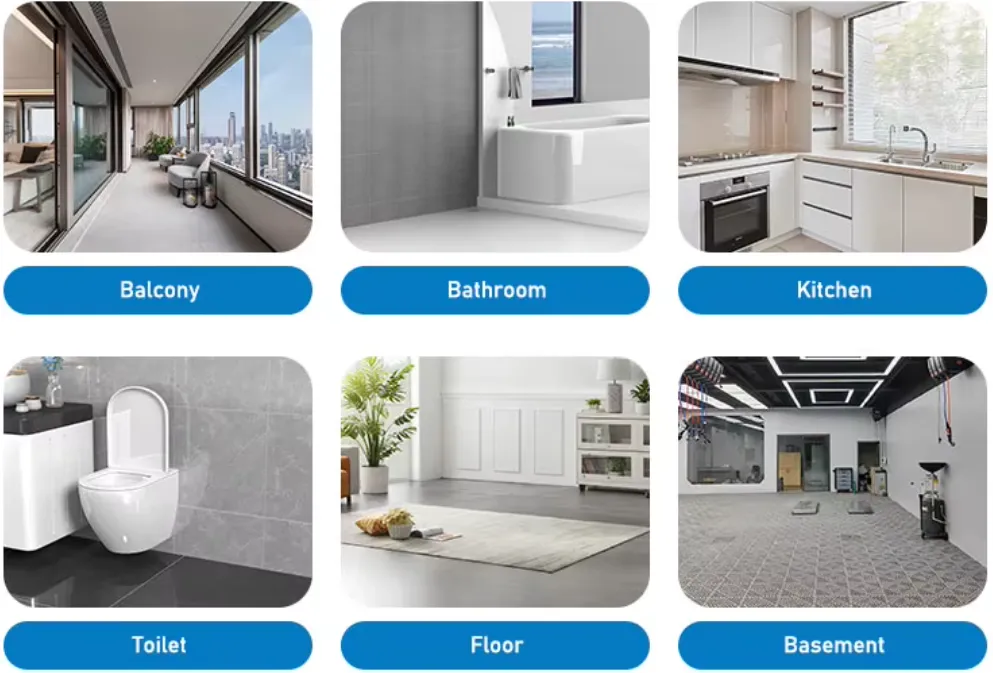

Søknadsomfang

- Roof waterproofing: It acts as a high-performance polyurethane waterproof coating for roof, applicable to all new/old flat or sloped roofs, gutters, and eaves—particularly effective for irregular-shaped parts on roof structures.

- Ground building areas: It’s widely used in indoor spaces (toilets, bathrooms, kitchens, balconies, floors) and exterior wall waterproofing/moisture-proof finishing. It also functions as a qualified polyurethane waterproof coating for wood, catering to waterproofing needs of wood-based substrates in relevant indoor sections.

- Underground structures: As a dependable polyurethane waterproof coating for concrete, it’s suitable for waterproofing projects of concrete-based facilities like underground interior/exterior walls, basement slabs, underground tunnels, and elevator shafts.

- Composite applications: It can be used in combination with various waterproof rolls or other waterproof coatings to boost waterproofing effects and prolong service life. When compounded with SBS waterproof rolls, its waterproofing durability can reach over 25 years.

Performance Index

| Serienummer | Punkt | Technical Indicators | |

|---|---|---|---|

| Type I | Type II | ||

| 1 | Tensile Strength (Mpa) ≥ | 1.0 | 1.5 |

| 2 | Elongation at Break (%) ≥ | 300 | |

| 3 | Low Temperature Flexibility (Bend 180° around φ10mm rod) | -10°C, No Cracks | -20°C, No Cracks |

| 4 | Water Impermeability (0.3Mpa, 30min) | Impermeable | |

| 5 | Solid Content (%) ≥ | 65 | |

| 6 | Drying Time (h) - Surface Dry ≥ | 4 | |

| Drying Time (h) - Actual Dry ≥ | 8 | ||

| 7 | Tensile Strength Retention Rate (%) after Treatment - Heat Treatment ≥ | 80 | |

| Tensile Strength Retention Rate (%) after Treatment - Alkali Treatment ≥ | 60 | ||

| Tensile Strength Retention Rate (%) after Treatment - Acid Treatment ≥ | 40 | ||

| Tensile Strength Retention Rate (%) after Treatment - Artificial Weathering Aging Treatment* ≥ | - | 80-150 | |

| 8 | Elongation at Break (%) after Treatment - Heat Treatment ≥ | - | |

| Elongation at Break (%) after Treatment - Alkali Treatment ≥ | 200 | ||

| Elongation at Break (%) after Treatment - Acid Treatment ≥ | - | ||

| Elongation at Break (%) after Treatment - Artificial Weathering Aging Treatment* ≥ | - | 200 | |

| 9 | Heating Expansion and Contraction Rate (%) - Elongation ≥ | 1.0 | |

| Heating Expansion and Contraction Rate (%) - Shrinkage ≥ | 1.0 | ||

Precautions

- Before construction, the coating should be fully stirred evenly. Do not add water arbitrarily except for the primer, so as to ensure quality.

- When laying reinforcing fabric, it should generally be pasted during the application of the second coating layer.

- Construction is strictly prohibited when the temperature is below 5°C or in rainy, snowy, or freezing weather. Do not perform other operations on the coating layer before the film is completely dry, so as not to damage the protective layer and affect the waterproof effect.

- To ensure the waterproof effect, it is recommended that the dosage of this coating be more than 2.5 kg per square meter.

- Settling is normal; just stir evenly before use.

Construction Method

- Construction UsageWhen the waterproof layer coating thickness is 1.0mm, the dosage ranges from about 1.8kg/m² to 2.2kg/m² (actual usage depends on the base layer condition and coating thickness; for a total thickness of 1.5-2.0mm, it’s recommended to use over 2.5kg/m²).

- Construction ThicknessThe thickness of the waterproof layer coating shall not be less than 1.5mm, while the thickness of the vertical surface coating shall not be less than 1.2mm.

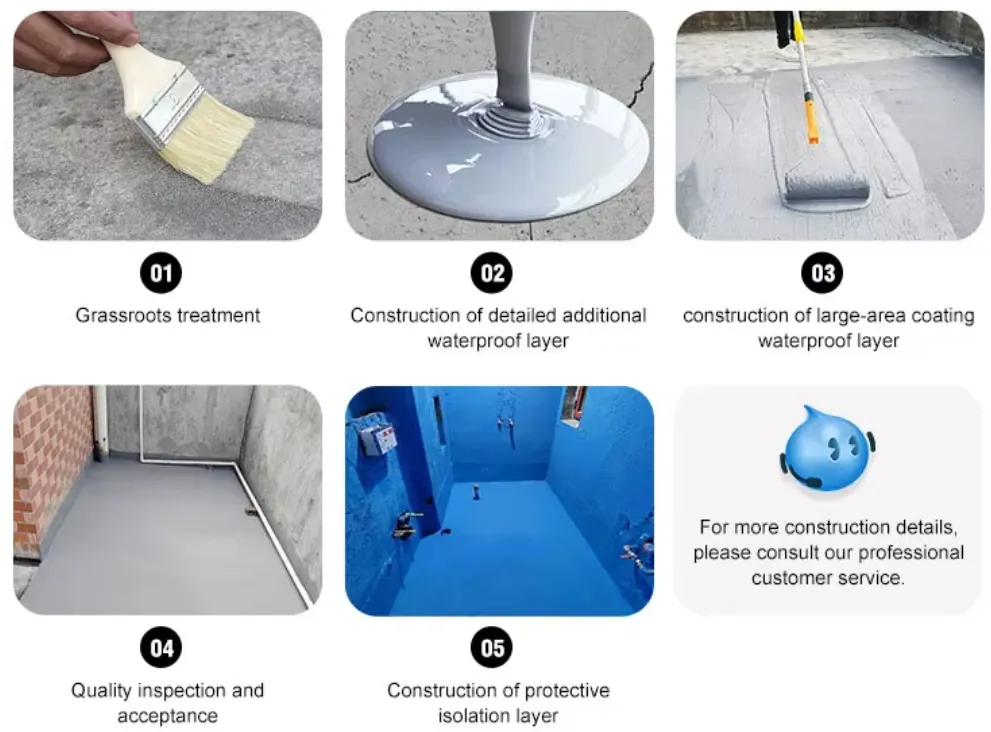

- Construction Technology ProcessThe overall workflow (a core part when learning how to apply polyurethane waterproof coating) is:Grassroots treatment → Construction of detailed additional waterproof layer → Construction of large-area coating waterproof layer → Quality inspection and acceptance → Construction of protective isolation layer

- Detailed Construction Steps

- Grassroots Treatment: The base layer must be flat, firm, clean, and free of visible water; internal and external corners should be shaped into arcs. For old roofs, remove the original cracked, blistered waterproof layer and dust, repair sunken/damaged areas, and block leaks first. Special parts (water outlets, expansion joints) need flexible sealing. The brushing sequence follows: internal/external corners → vertical surfaces → large-area construction.

- Primer Construction: Mix water and the coating at a 1:3 weight ratio, stir evenly before use. The primer boosts the coating’s permeability to the base layer and enhances adhesion.

- Coating Application: Applicable methods include rolling, scraping, brushing, or polyurethane waterproof coating spray; the thin-layer multiple coating method is recommended (avoid over-thick single coats). Apply 3-4 coats in total (to reach 1.5-2.0mm thickness), and only apply the next coat after the previous one dries and forms a film. Lay reinforcing fabric in structurally weak sections.

- Key Points of Construction

- Construction temperature should be 5°C~35°C; construction is prohibited in rainy, snowy, or freezing weather (below 5°C).

- After each coat dries (surface-dry), conduct quality inspection; promptly repair missed coating or blistering areas.

- For detailed nodes (internal/external corners, pipe roots, drainage outlets), apply 2-3 coats of additional waterproof layers.

Customer Reviews

About Our Factory

Great Ocean Waterproof Technology Co., Ltd. (formerly Weifang Great Ocean New Waterproof Materials Co., Ltd.) was established in 1999 and is located in Taitou Town, Shouguang City—the heart of China’s largest waterproof materials production base.

Covering an area of 26,000 square meters, our factory has developed into a national high-tech enterprise integrating scientific research, production, and sales in the waterproofing industry. After more than 25 years of continuous innovation, we now operate multiple advanced production lines for waterproof membranes, sheets, and coatings that meet domestic leading standards.

We specialize in a full range of waterproofing solutions, including the JY-951 Waterborne Polyurethane Waterproof Coating, single- and double-component polyurethane coatings, polymer cement (JS) coatings, polyethylene/polypropylene (polyester) waterproof membranes, PVC, TPO, CPE, non-asphalt reactive pre-laid polymer self-adhesive membranes, modified asphalt membranes, root-resistant membranes, spray-applied rubber asphalt coatings, non-curing rubber asphalt coatings, and dozens of other professional waterproof products.

Backed by strong technical expertise, a team of professional engineers and technicians, state-of-the-art equipment, and complete testing instruments, we ensure stable and reliable product quality. Our products have been certified by national authoritative testing institutions and we have earned prestigious honors including:

- National Ministry of Agriculture “Comprehensive Quality Management Compliance”

- ISO Quality Management System Certification

- “Nationally Authorized Testing Qualified Product” by China Quality Inspection Association

- Shandong Province Industrial Construction Product Registration Certificate

- Industrial Product Production License

Adhering to the principles of integrity, pragmatism, and innovation, Great Ocean Waterproof Technology Co., Ltd. is committed to the philosophy of “win-win and shared success.” With high cost-performance products and excellent service, our products are widely sold in more than 20 provinces across China and exported to numerous countries and regions worldwide, earning consistent praise from customers.

We look forward to cooperating with you to create a drier, safer future together!

|  |

|  |