PVC Polyvinyl Chloride Waterproofing Membrane PVC Membrane Waterproofing

Great Ocean Waterproof operates as a manufacturer in China, specializing in PVC Polyvinyl Chloride Waterproofing Membrane for roofing, basements, tunnels, and ponds. The factory in Shandong Province uses standard extrusion and calendering processes to produce this pvc sheet membrane for waterproofing in thicknesses from 1.2mm to 2.0mm. As a common pvc waterproof membrane option, it resists root penetration and chemical exposure in typical installations. Contact us for current price details based on volume and specifications.

Product Introduction

PVC waterproofing membrane is a polymer-based sheet material designed for moisture protection in construction applications. It is produced by extruding polyvinyl chloride (PVC) resin combined with additives such as plasticizers, stabilizers, anti-aging agents, ultraviolet absorbers, lubricants, and fillers to form a single-layer roll.

This membrane provides a barrier against water infiltration, suitable for use in roofing, basements, tunnels, and other structural elements where durability and flexibility are required. It resists UV exposure, chemicals, and environmental wear, with a typical service life exceeding 20 years under standard conditions.

As a pvc sheet membrane for waterproofing, it comes in thicknesses of 1.2 mm, 1.5 mm, 1.8 mm, or 2.0 mm, with a standard length of 25 meters and widths of 1.0 meter or 2.0 meters. Installation involves methods like mechanical fastening or adhesion, depending on the substrate.

Great Ocean Waterproof, as a pvc waterproofing membrane manufacturer, supplies this product in various specifications to meet project needs. For details on pvc waterproofing membrane price, options vary based on thickness, quantity, and regional factors; inquiries can be directed to our sales team for current quotes.

| Thickness(mm) | 1.2 / 1.5 / 1.8 / 2.0 | Length(m) | 25 | Width(m) | 1.0 / 2.0 |

PVC Waterproofing Membrane Specifications

Project | Waterproof | ||

Application | Basement, subway, tunnel,etc | ||

Type | Waterproof membrane | ||

Product Name | PVC Waterproofing Membrane | ||

Width | 1m,2m,Customizable | ||

Length | 20m/roll | ||

Thickness | 1.2mm, 1.5mm, 2.0mm | ||

Color | grey/green/orange,Others | ||

Advantage | Good flexibility, easy to bend not easy to break, anti aging, anti corrosion | ||

Material | Polyvinyl chloride resin, polyester fiber fabric, glass fiber, etc |

Product Features

- Extended durability: Roof installations last over 30 years; underground applications reach up to 50 years with proper installation of this pvc sheet waterproof membrane.

- Mechanical stability: High tensile strength, notable elongation, and minimal dimensional change after heat exposure.

- Cold-weather performance: Maintains flexibility at low temperatures and adapts to seasonal shifts.

- Vegetation compatibility: Resists root penetration, enabling use in green roof systems.

- Puncture and impact tolerance: Withstands site traffic and minor impacts during and after installation.

- Installation efficiency: Requires minimal overlap, allows customer-side welding for seamless joints, and produces no emissions during heat welding of pvc waterproofing membrane.

- Chemical resistance: Handles exposure to acids, alkalis, and oils in specialized environments.

- Detailing ease: Good plasticity speeds up corner and penetration treatments.

- Lifecycle cost: Simple inspection and repair routines keep long-term expenses low.

- Surface properties: Light-colored finish reflects UV rays; coil orientation reduces heat buildup on the exposed face.

Performance

| No. | Item | Indicator | |||||

|---|---|---|---|---|---|---|---|

| H | L | P | G | GL | |||

| 1 | Thickness of resin layer on the middle tire base/mm ≥ | — | 0.40 | ||||

| 2 | Tensile Property | Maximum tensile force/(N/cm) ≥ | — | 120 | 250 | — | 120 |

| Tensile strength /MPa ≥ | 10.0 | — | — | 10.0 | — | ||

| Elongation at maximum tension/% ≥ | — | — | 15 | — | — | ||

| Elongation at break/% ≥ | 200 | 150 | — | 200 | 100 | ||

| 3 | Heat treatment size change rate/% ≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Low temperature bending property | -25℃ No cracks | |||||

| 5 | Impermeability | 0.3MPa, 2h, waterproof | |||||

| 6 | impact resistance | 0.5kg.m, waterproof | |||||

| 7 | Resistance to static loadsa | — | — | 20kg,waterproof | |||

| 8 | Joint peel strength/(N/mm) ≥ | 4.0 | 3.0 | ||||

| 9 | Right angle tear strength/(N/mm) ≥ | 50 | — | — | 50 | — | |

| 10 | trapezoid tear strength/N ≥ | — | 150 | 250 | — | 220 | |

| 11 | Water absorption rate(70℃,168h)/% | After immersion in water ≥ | 4.0 | ||||

| After air drying ≤ | -0.40 | ||||||

PVC Polyvinyl Chloride Waterproofing Membrane Applications

The PVC membrane for waterproofing is installed across a range of civil-engineering and building-envelope projects:

- Roof systems – Single-ply cover for industrial plants, warehouses, offices, schools, hospitals, and other flat or low-slope structures.

- Mechanically fastened roofs – Reinforced (L, P, G, GL) rolls secure with screws and plates in high-wind zones.

- Fully adhered roofs – Fleece-backed rolls bond directly to insulation or substrate with contact adhesive.

- Homogeneous roofs – Non-reinforced (H) rolls serve as the primary barrier in protected-membrane assemblies.

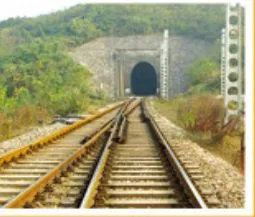

- Underground structures – Basements, parking garages, metro stations, and utility tunnels.

- Water-containment – Reservoirs, artificial lakes, canals, and fish ponds.

- Bridge decks – Between wearing course and concrete substrate.

- Planted/green roofs – Root-resistant layer beneath soil and vegetation.

- Tunnels & rail corridors – Liner for cut-and-cover sections and side-wall drainage.

Typical pvc waterproofing membrane application follows hot-air or solvent welding at seams, with mechanical fix or full adhesion depending on the roll type and substrate. Great Ocean Waterproof supplies all grades for the above uses; site-specific details are available on request.

|  |  |

|  |  |

Construction

Mechanical Fixed Layer System

Construction Technology

Grassroots treatment → Laying vapor barrier layer → Laying insulation board → Pre-laying roll material → Mechanical fixing roll material

Materials → Hot welding of overlapping area → Processing of detailed nodes → Quality inspection and acceptance

Key Points of Construction

- Cleaning the base layer: The base layer should be solid, flat, clean, and dry.

- Laying vapor barrier layer: The vapor barrier layer is laid empty, and the overlapping surface is bonded with double-sided tape.

- Laying insulation board: Staggered laying and mechanical fixation of insulation board.

- Pre-laid rolls: Rolls should be laid in the predetermined position, flat, straight, and without twisting or crossing.

- Mechanical fixation of coil material: The lower layer of TPO/PVC coil material is mechanically fixed in the pre-laid overlap area.

- Overlap zone hot welding: Clean the welding zone of adjacent coils and perform hot air welding using a manual welding gun (or automatic welding machine).

- Detail node processing: Processing typical details such as internal and external corners on three sides, pipe edges and roots.

Roll Bonding System

Construction Technology

Grassroots treatment → Detailed node treatment → Pre-laid roll material → Main waterproof layer construction → Exhaust compaction → Quality inspection and acceptance

Key Points of Construction

- Cleaning the base layer: The cement concrete base layer should be solid, flat, dry, and clean.

- Detail node processing: Non-reinforced waterproofing membrane is used as an additional waterproof layer for details, and adhesive is used to bond with the base layer and the membrane.

- Pre-laid rolls: TPO/PVC rolls should be laid in the predetermined position, flat, straight, and without twisting or crossing.

- Main waterproof layer construction: The waterproof layer of the main part is bonded to the base layer with matching adhesive, which is applied to the base layer and the bottom surface of the roll material.

- Exhaust compaction: After drying the adhesive until it no longer sticks to the touch, immediately lay it and compact it with the exhaust as the roll rolls.

TPO vs. PVC Waterproofing Membrane: Side-by-Side Comparison

| Property | TPO Membrane | PVC Membrane |

|---|---|---|

| Base Polymer | Thermoplastic Polyolefin (polyethylene + polypropylene blend) | Polyvinyl Chloride (PVC) resin |

| Reinforcement Types | H (non-reinforced), L (fabric scrim), P (polyester scrim), G (glass fiber), GL (glass + polyester) | Same codes: H, L, P, G, GL |

| Resin Layer Thickness on Scrim (mm) | Not specified in standard tables | ≥ 0.40 mm (G type) |

| Tensile Strength (MPa) | 8–12 MPa (varies by grade) | ≥ 10.0 MPa (H, G types) |

| Maximum Tensile Force (N/cm) | 100–150 N/cm | ≥ 120 N/cm (L, G types) / ≥ 250 N/cm (P type) |

| Elongation at Break (%) | 500–800 % | ≥ 100 % (GL) / ≥ 150 % (L) / ≥ 200 % (H, G) |

| Heat Treatment Dimensional Change (%) | ≤ 1.0 % | ≤ 0.1 % (G, GL) / ≤ 0.5 % (P) / ≤ 1.0 % (L) / ≤ 2.0 % (H) |

| Low-Temperature Flexibility | –40 °C no cracks (typical) | –25 °C no cracks |

| Impermeability | 0.3 MPa, 2 h | 0.3 MPa, 2 h |

| Impact Resistance | 0.5 kg·m | 0.5 kg·m |

| Static Load Resistance | 20 kg | 20 kg |

| Joint Peel Strength (N/mm) | 3.0–6.0 | ≥ 3.0 (GL) / ≥ 4.0 (H) |

| Right-Angle Tear Strength (N/mm) | 40–60 | ≥ 50 (H, G) |

| Trapezoid Tear Strength (N) | 200–300 | ≥ 150 (L) / ≥ 220 (GL) / ≥ 250 (P) |

| Water Absorption (70 °C, 168 h) | ≤ 2.0 % | ≤ 4.0 % (immersion) / –0.40 % (air dry) |

| Seam Method | Hot-air welding | Hot-air welding |

| UV & Aging | Excellent (no plasticizer migration) | Good (plasticizer can migrate over decades) |

| Root Resistance | Standard for green roofs | Standard for green roofs |

| Typical Service Life | Roof: 25–30 years / Underground: 40–50 years | Roof: 20–30 years / Underground: 50+ years |

| Key Advantage | Zero plasticizer = no long-term embrittlement | Proven track record, slightly lower cost per m² |

| Key Drawback | Slightly higher material cost | Plasticizer migration can reduce flexibility after 15–20 years |

Bottom Line

- Choose TPO when plasticizer-free aging and maximum elongation are priorities (e.g., exposed roofs, green roofs).

- Choose PVC when budget, proven 50-year underground performance, or regional code familiarity drives the decision.

Great Ocean Waterproof supplies both TPO and PVC sheet membranes; contact us for project-specific recommendations and current pricing.

FAQ – PVC Polyvinyl Chloride Waterproofing Membrane

1. What is the difference between H, L, P, G, and GL types of PVC membrane? H = homogeneous (non-reinforced); L = polyester fabric scrim; P = heavy polyester scrim; G = glass-fiber scrim; GL = glass + polyester composite. Reinforced grades (L/P/G/GL) are used for mechanical fastening; H is for fully adhered or ballasted systems.

2. How long does a PVC waterproofing membrane last? Roofs: 20–30 years exposed, 30+ years under ballast or green roof. Underground: 50+ years when protected from UV and mechanical damage.

3. Can PVC membrane be used for green/vegetated roofs? Yes. All grades pass root-penetration tests (EN 13948 / FLL) and are suitable under soil, drainage layers, and vegetation.

4. What installation methods are available?

- Mechanically fastened (screws + plates in overlap)

- Fully adhered (contact adhesive or PU glue)

- Loose-laid + ballasted (gravel or pavers) Seams are always hot-air welded.

5. Is hot-air welding required, or can I use glue for seams? Seams must be hot-air welded (180–220 °C) for water-tightness. Glue or tape is only for temporary fixing or small repairs.

6. What thickness should I choose? 1.2 mm – light-duty roofs, internal use 1.5 mm – standard single-ply roof 1.8–2.0 mm – high-traffic roofs, tunnels, bridges, underground

7. Does the membrane contain plasticizers that migrate over time? Yes. Modern formulations minimize migration, but long-term flexibility loss can occur after 15–20 years in exposed conditions. Use TPO if zero-migration is critical.

8. What colors are available? Standard: light grey, white (high reflectivity). Custom colors on MOQ.

9. Can PVC membrane be walked on after installation? Yes, once seams are welded and inspected. Use protection boards under heavy equipment.

10. How do I repair a puncture? Cut a round patch (min. 10 cm beyond damage), clean both surfaces, hot-air weld in place, and probe seam.

11. Is the membrane recyclable? Yes. Factory off-cuts and clean demolition material can be returned to PVC recycling streams.

12. What is the standard roll size? Thickness: 1.2 / 1.5 / 1.8 / 2.0 mm Width: 1.0 m or 2.0 m Length: 25 m Weight: 1.5–2.5 kg/m² depending on grade.

13. Do you supply fleece-backed rolls for direct adhesion to concrete? Yes. Fleece-backed (FB) versions are available for PU or epoxy bonding systems.

14. What warranty do you offer? Material warranty: 10–15 years (thickness-dependent). System warranty up to 20 years with certified installers.

15. Where can I see test reports? EN 13956 (CE), ASTM D4434, GB 12952-2011 reports are available on request.

Contact Great Ocean Waterproof for project-specific advice or samples.

About Our Factory

Great Ocean Waterproof Technology Co., Ltd. (formerly Weifang Great Ocean New Waterproof Materials Co., Ltd.) is located in Taitou Town, Shouguang City—the heart of China’s largest waterproofing materials production base. Established in 1999, we operate as a high-tech enterprise integrating R&D, manufacturing, and sales of advanced waterproofing solutions.

Our 26,000 m² facility houses multiple state-of-the-art production lines for roll membranes, sheet materials, and liquid coatings. Key product lines include PVC waterproofing membrane, TPO, CPE, polyethylene-polyester composite, self-adhesive polymer sheets, root-resistant membranes, modified bitumen rolls, polyurethane coatings(JS composite, spray-applied rubber asphalt, and more—over 40 specialized systems in total.

Equipped with cutting-edge extrusion, calendering, and coating technology, we maintain full in-house testing labs to ensure batch-to-batch consistency. All PVC membrane waterproofing products meet GB 12952-2011, EN 13956, and ASTM standards, verified by national authorities.

Certifications include:

- National Ministry of Agriculture “Total Quality Management Compliance”

- ISO 9001 Quality Management System

- China Quality Inspection Association “Nationally Certified Product”

- Shandong Province Industrial Product Filing & Production License

With a strong technical team and decades of field experience, we supply reliable waterproofing systems to projects across 20+ provinces in China and export to multiple international markets. Great Ocean Waterproof remains committed to contract integrity, product stability, and customer trust.