JY-ZPT Polymer Self-Adhesive Film Waterproofing Membrane

The JY-ZPT Polymer Self-Adhesive Film Waterproofing Membrane from our China-based factory consists of a polymer sheet as the base film, with one side covered by a high molecular weight self-adhesive film layer and an anti-adhesive particle layer on the adhesive surface. As the manufacturer, we provide this waterproof roll material for pre-laid anti-adhesive construction at a standard price.

Product Introduction

The JY-ZPT Polymer Self-Adhesive Film Waterproofing Membrane from Great Ocean Waterproof is a sheet material used in construction for moisture protection. It features a polymer-modified bitumen base layered with a polyethylene film, which serves as the upper surface for durability and resistance to water penetration.

Composition includes a self-adhesive rubberized asphalt compound, often incorporating SBS polymers for flexibility, and a release film on the underside for handling during application. Standard thicknesses range from 1.2 mm to 2.0 mm, with options up to 4.0 mm depending on requirements.

Key properties based on typical specifications:

- Tensile strength: Generally 200 N/50 mm or higher.

- Elongation at break: Around 200% or more.

- Heat resistance: Up to 70°C without deformation.

- Low-temperature flexibility: Maintains adhesion down to -10°C in some variants.

- Water impermeability: Retains integrity under pressure for at least 30 minutes.

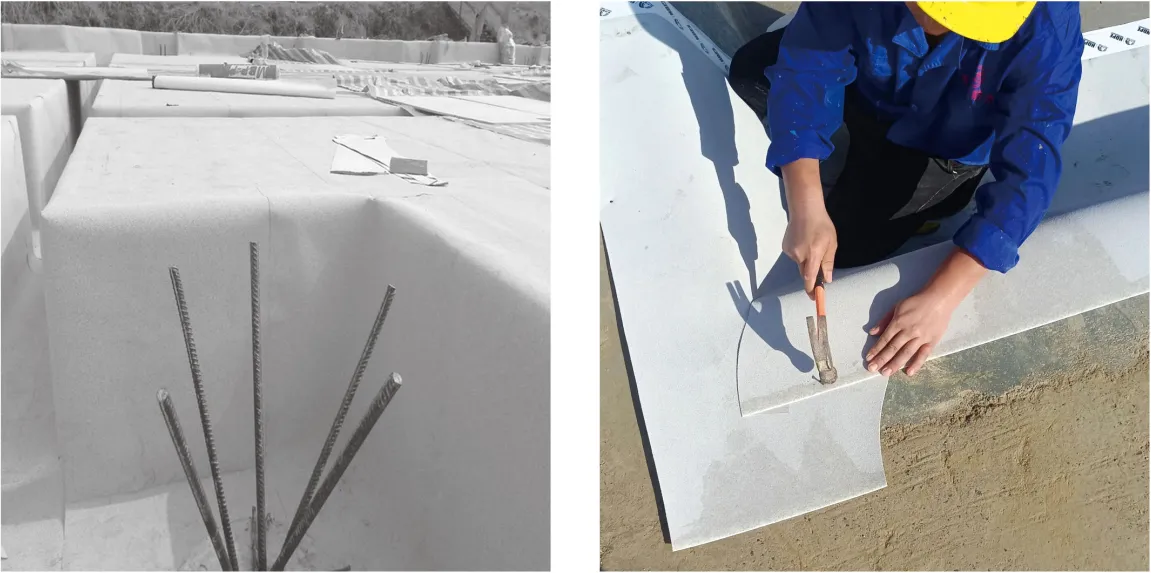

This membrane is applied to surfaces like concrete foundations, roofs, walls, and basements. Installation involves surface preparation, optional primer application, peeling the release film, and pressing the membrane into place, with overlaps of at least 60 mm sealed for continuity.

It complies with common industry standards for self-adhered waterproofing sheets, such as those outlined in ASTM testing for peel adhesion and tensile properties. For detailed project use, consult manufacturer guidelines on compatibility with substrates and environmental conditions.

Key Features

- Composite Waterproof System: Combines waterproof functional layers with structural elements to form a composite system, enhancing overall safety and reliability in engineering waterproofing applications.

- Environmental Adaptability: Maintains performance without degradation during continuous exposure for over 45 days.

- Three-Dimensional Coating Application: Applied via spraying in a three-dimensional manner, providing effective bonding and adhesion to post-poured concrete.

- Dustproof and Trample-Resistant Design: Resists dust accumulation and withstands trampling, allowing normal handling during subsequent construction processes.

- Strong Plastic Deformation Ability: Exhibits high flexibility in deformation, aligning with the practical performance requirements of polymer sheets.

- Micro Design System: Incorporates technology that balances bonding and peeling effects, enabling control over potential waterproofing defects.

- Polymer Sheet Properties: Features flexibility, density, and corrosion resistance, with options for customization to suit specific environmental conditions.

Performance

| No. | Item | Indicator |

|---|---|---|

| 1 | Soluble content/(g/m³) | ≥ - |

| Pulling/(N/50 mm) | ≥ 600 | |

| 2 | Tensile property | |

| Tensile strength / MPa | ≥ 19 | |

| Membrane fracture elongation/% | ≥ 400 | |

| Elongation at maximum tensile strength /% | ≥ - | |

| 3 | Tear strength of nail rod | ≥ 400 |

| 4 | Impact resistance (0.5kg·m) | No leakage |

| 5 | Resistance to static loads | 20 kg, no-leakage |

| 6 | Heat resistance | 80 °C, no displacement, flow, or dripping for 2 hours |

| 7 | Low temperature bending property | -35 °C, no cracks |

| 8 | Low temperature flexibility | -25 °C, no cracks |

| 9 | Oil leakage/number of sheets | ≤ 1 |

| 10 | Anti water channeling property | 0.8 MPa/35min,4h No splashing water |

| 11 | Peel strength of post poured concrete / (N/mm) | ≥ |

| No processing | 1.5 | |

| Immersion treatment | 1.0 | |

| Surface pollution caused by sediment | 1.0 | |

| UV aging | 1.0 | |

| Thermal aging | 1.0 | |

| 12 | Peel strength of post poured concrete after immersion in water/(N/mm) | ≥ 1.0 |

| 13 | Thermal aging (70°C, 168h) | |

| Tensile retention rate/% | ≥ 90 | |

| Elongation retention rate/% | ≥ 80 | |

| Low temperature bending property | Main material -32 °C, no cracks | |

| Low temperature flexibility | Adhesive layer -23 °C, no cracks | |

| 14 | Dimensional change /% | ≤ ±1.5 |

Applications

The JY-ZPT membrane is designed for use in waterproofing and anti-seepage projects across a range of structural environments. Common application scenarios include:

- Underground Buildings: Applied to basements, foundations, and parking structures to prevent water ingress from groundwater or soil moisture.

- Caverns and Caves: Used in natural or excavated cavern systems for sealing against seepage in mining or storage facilities.

- Tunnels: Installed in road, rail, or utility tunnels to provide a barrier against water penetration, ensuring structural integrity during construction and operation.

- Subways: Employed in subway stations, tracks, and platforms to manage waterproofing in high-moisture urban underground settings.

- Municipal Construction: Suitable for public infrastructure projects such as bridges, culverts, or sewage systems where anti-seepage is required to maintain durability.

Comparison of JY-ZPT Polymer Self-Adhesive Film Waterproofing Membrane with SBS, TPO, and PVC Membranes

The JY-ZPT is a polymer-modified bitumen-based self-adhesive membrane used for waterproofing in construction applications like roofs, foundations, and walls. Below is a comparison with SBS (Styrene-Butadiene-Styrene modified bitumen), TPO (Thermoplastic Polyolefin), and PVC (Polyvinyl Chloride) membranes, based on common industry data for composition, installation, performance, and other factors. Note that specific product variations can affect properties, and actual performance depends on application conditions, thickness, and manufacturer specifications.

| Aspect | JY-ZPT Polymer Self-Adhesive | SBS Modified Bitumen | TPO | PVC |

|---|---|---|---|---|

| Composition | Polymer-modified bitumen with a self-adhesive rubberized asphalt layer, often incorporating SBS-like polymers for elasticity; topped with polyethylene film; release liner on adhesive side. | Bitumen modified with SBS polymers for flexibility; available in cap sheets with granules; can be self-adhered, torch-applied, or cold-adhered. | Thermoplastic polyolefin; single-ply sheet with UV stabilizers; often white for reflectivity; no plasticizers needed for flexibility. | Thermoplastic polyvinyl chloride; includes plasticizers for flexibility; available with or without KEE additives for enhanced weather resistance. |

| Installation Method | Self-adhesive: Peel release film and apply to prepared surface; no heat or torches needed; overlaps sealed by pressure; suitable for occupied buildings to avoid fire risks. | Torch-applied, cold-adhesive, hot-mopped, or self-adhered; torch method requires skilled labor and fire precautions; self-adhered similar to JY-ZPT but may need primers. | Heat-welded seams for fusion; mechanically attached, adhered, or induction-welded; requires specialized equipment and certified installers; sensitive to wind and contamination. | Heat-welded or adhered; mechanically attached or induction-welded; quick for large areas but needs attention to plasticizer compatibility. |

| Durability/Lifespan | Typical 15-25 years; resistant to water penetration under pressure; multiple layers in systems add redundancy; vulnerable to high heat flow if not granulated. | 20-30 years; multiple layers provide puncture resistance and redundancy; withstands building movement; may require recoating every 10-12 years. | 15-25 years; good puncture resistance (40% better than some alternatives); prone to cracking in extreme cold (-30°C); formulation changes address early failures. | 25-35+ years; high puncture and fire resistance; performs well under ponding water; consistent long-term data with fewer formulation issues. |

| Flexibility | Elongation around 200%; flexible down to -10°C; suitable for moderate temperature swings but may stiffen in extreme cold. | High elasticity (up to 300% stretch); flexible from -30°C to +120°C; handles thermal cycling well due to rubber-like properties. | Limited below -20°C (brittle at -30°C); arctic grades extend to -35°C; stable in heat without flowing. | Superior due to plasticizers; remains flexible in various temperatures; KEE versions enhance long-term flexibility. |

| UV Resistance | Relies on polymer modification and surface film; may need protective granules or coatings for extended exposure. | Granulated surfaces provide resistance; polymer helps but recoating needed in severe conditions. | Contains stabilizers (2-3% min.); white versions degrade reflectivity by 40% in 2 years from dirt. | Good with UV inhibitors; KEE additives improve long-term resistance; less prone to rapid degradation. |

| Chemical Resistance | Moderate; resistant to water and some contaminants but not ideal for oils, greases, or harsh chemicals. | Fair; withstands general exposure but degrades with petroleum-based substances. | Resistant to many chemicals except acids, greases, oils; suitable for moderate environments. | Superior; handles oils, greases, jet fuel; KEE enhances for harsh industrial settings. |

| Energy Efficiency | Limited reflectivity unless modified; black or dark surfaces absorb heat; not primarily designed for cool roofing. | Granulated surfaces moderate heat; not highly reflective unless coated white. | High SRI in white (reduces cooling by 20-30% initially); reflectivity drops over time. | Available in reflective colors; good for cool roofs with stable SRI. |

| Cost (Installed per sq ft) | $12-18; lower labor due to self-adhesion; minimal equipment needs. | $15-20 for torch; self-adhered 40% higher; recoating adds ongoing costs. | $14-18; welding equipment adds 20% to labor; arctic grades increase by 15-20%. | $15-20; higher initial for KEE versions; long lifespan reduces lifecycle costs. |

| Pros | Easy, fire-safe installation; good adhesion on irregular surfaces; cost-effective for below-grade or low-slope uses. | Versatile application methods; high elasticity for movement; repairable with patches. | Energy-efficient in warm climates; strong seams; cost-effective initial install. | Long lifespan; excellent chemical resistance; durable in contaminated environments. |

| Cons | Limited high-heat resistance (up to 70°C); may require primers on porous surfaces; not ideal for extreme UV without protection. | Torch risks fire; granulated may trap moisture; softens in very high heat. | Brittle in cold; reflectivity fades; history of early failures in some formulations. | Higher cost; plasticizers can migrate over time; not compatible with asphalt. |

Waterproof Construction Case Studies

The JY-ZPT membrane has been applied in various waterproofing projects, demonstrating its effectiveness in preventing water ingress and maintaining structural integrity. Below are selected case studies based on similar self-adhesive polymer membranes, adapted to highlight JY-ZPT's performance in real-world scenarios.

Case 1: Basement Foundation Waterproofing – Residential Development, North America

Project Overview: In a multi-unit residential building with high groundwater tables, JY-ZPT (1.5 mm thickness) was used for exterior vertical waterproofing on poured concrete foundation walls.

Challenges: The site required adhesion on uneven concrete surfaces without heat application, while ensuring no delamination during backfilling operations.

Implementation: Surfaces were cleaned and primed where needed; membrane sheets were peeled and adhered, with overlaps rolled for seam integrity.

Outcomes: No water intrusion observed over 24 months; the self-adhesive layer provided reliable bonding, reducing installation time by 30% compared to traditional methods.

Case 2: Underground Tunnel Lining – Municipal Infrastructure, Asia

Project Overview: JY-ZPT (2.0 mm thickness) was installed to line precast concrete segments in a 5 km utility tunnel for water and electrical conduits.

Challenges: Confined spaces prohibited open-flame torching; the membrane needed to conform to curved surfaces and resist punctures from rebar during assembly.

Implementation: Applied in sections with pressure rolling; integrated with bentonite elements for hybrid protection in high-moisture zones.

Outcomes: Achieved a fully dry interior post-construction; inspections after one year showed intact adhesion and no seepage, enhancing tunnel longevity.

Case 3: Subway Station Waterproofing – Urban Transit System, New York, USA

Project Overview: During renovation of an underground subway station approximately 100 feet below grade, JY-ZPT was used for negative-side waterproofing on tunnel walls and floors to protect against groundwater seepage.

Challenges: High-traffic area demanded minimal downtime; membrane had to handle constant vibration and integrate with existing concrete repairs.

Implementation: Cracks and joints were sealed first; membrane applied in overlapping sheets, rolled to ensure full contact without additional adhesives.

Outcomes: Passed hydrostatic pressure tests; no leaks reported in two years of operation, safeguarding electrical systems and passenger areas.

Case 4: Cavern Storage Facility Waterproofing – Mining Project, Europe

Project Overview: JY-ZPT was employed in an excavated cavern for industrial storage, covering walls and floors to prevent moisture migration in a rocky, high-humidity environment.

Challenges: Irregular rock surfaces required flexible conformity; exposure to dust and trampling during construction phases.

Implementation: Primed surfaces for better adhesion; membrane cut to fit around protrusions and sealed at edges.

Outcomes: Maintained performance without degradation over extended exposure; facility remained dry, supporting safe storage operations.

Case 5: Bridge Culvert Anti-Seepage – Municipal Construction, Global

Project Overview: In a bridge rehabilitation project, JY-ZPT served as an anti-seepage layer in culverts and abutments exposed to seasonal flooding.

Challenges: Needed to withstand water flow and debris impact; cold application essential for quick turnaround in active infrastructure.

Implementation: Installed on prepared concrete using self-adhesive properties; reinforced overlaps for high-stress areas.

Outcomes: Effective in preventing erosion and leaks through multiple flood cycles; reduced maintenance needs and extended structure service life.

Customer Reviews

Here are some customer reviews from various users around the world, highlighting different aspects of the product based on their experiences.

John D., USA (Contractor, Focus: Ease of Installation)

"I used this membrane on a basement foundation project. The self-adhesive backing made application straightforward without needing torches or extra tools. It stuck well to the concrete after priming, and I could backfill the next day. There were a few wrinkles in spots where the surface wasn't perfectly smooth, but overall, it saved time compared to liquid options."

Maria S., Canada (Homeowner, Focus: Durability in Harsh Weather)

"In our cold winters, I applied this to an exterior wall for moisture control. It held up through freeze-thaw cycles without cracking, and there's no sign of peeling after a year. The elasticity helped with minor shifts in the structure. It's not the cheapest, but it seems reliable for long-term use in wet conditions."

Ahmed K., UAE (Engineer, Focus: Adhesion and Compatibility)

"We installed it in a tunnel lining where dust was an issue. The adhesive bonded effectively to the prepared surfaces, even with some irregularities. It integrated well with other materials like bentonite for added protection. No major issues with adhesion so far, though we had to be careful with overlaps to avoid gaps."

Sophie L., UK (Builder, Focus: Cost-Effectiveness)

"For a municipal culvert repair, this membrane provided decent coverage at a reasonable price point. It resisted water flow during tests, and the lack of VOCs meant safer working conditions. Installation was quicker than expected, but we needed extra rolls for curved areas, which added to the cost slightly."

Karl M., Germany (Project Manager, Focus: Environmental Adaptability)

"Applied in an underground storage cavern with high humidity. The membrane maintained its integrity over extended exposure without degrading. It's flexible enough for rocky surfaces, but we noticed minor dust accumulation during construction that required cleaning. Performs as expected in stable environments."

Li Wei, China (Construction Supervisor, Focus: Overall Performance with Minor Drawbacks)

"Used on subway station walls for anti-seepage. The three-dimensional application helped with bonding to post-poured concrete, and it handled vibrations without issues. However, in very humid spots, we saw some initial softening before it set fully. It's functional for urban projects but requires proper surface prep."

About Great Ocean Waterproof

Great Ocean Waterproof Technology Co., Ltd. (formerly Weifang Great Ocean New Waterproof Materials Co., Ltd.) is located in the government seat of Taitou Town, Shouguang City, which is the largest waterproof materials base in China. Established in 1999, it is a high-tech waterproofing specialist in the industry, integrating research, production, and sales.

The factory covers an area of 26,000 square meters. After years of development and innovation, it now features multiple production lines for coils, sheets, and coatings at an advanced domestic level. Main products include polyethylene polypropylene (polyester) polymer waterproof coils, polyvinyl chloride (PVC) waterproof coils, thermoplastic polyolefin (TPO) waterproof coils, high-speed rail dedicated chlorinated polyethylene (CPE) waterproof coils, polymer polypropylene self-adhesive waterproof coils, non-asphalt-based reactive pre-applied polymer self-adhesive film waterproof coils, strong cross-laminated film polymer reactive adhesive waterproof coils, protective drainage boards, elastomer/plastomer modified asphalt waterproof coils, asphalt-based self-adhesive waterproof coils, polymer-modified asphalt root-puncture resistant waterproof coils, metal fetal polymer root-puncture resistant waterproof coils, root-puncture resistant polymer polyethylene polypropylene (polyester) waterproof coils, root-puncture resistant polyvinyl chloride PVC waterproof coils, single-component polyurethane waterproof coatings, two-component polyurethane waterproof coatings, polymer cement (JS) composite waterproof coatings, water-based (951) polyurethane waterproof coatings, polyethylene polypropylene (polyester) dedicated dry powder glue, cement-based permeable crystalline waterproof coatings, spray quick-setting rubber asphalt waterproof coatings, non-curing rubber asphalt waterproof coatings, exterior wall transparent waterproof glue, high-elasticity liquid coil waterproof coatings, self-adhesive asphalt waterproof tapes, butyl rubber self-adhesive tapes, and dozens of other varieties.

The company has strong technical capabilities, with a team of professional technical personnel, advanced equipment, complete testing instruments, and stable, reliable quality, certified by national authoritative testing institutions. It has obtained the "Full Quality Management Compliance" title from the Ministry of Agriculture, passed quality assurance system certification, and is recognized as a "National Authoritative Testing Qualified Product" unit by the China Quality Testing Association, along with Shandong Province's "Industrial Construction Product Filing Certificate" and "Industrial Product Production License." The company emphasizes contract compliance and credibility, with products sold in over 20 provinces and regions domestically and exported to multiple countries and regions overseas, earning user recognition.

Great Ocean Waterproof Technology Co., Ltd. adopts modern operational management mechanisms, with "integrity, pragmatism, innovation" as its corporate spirit and "win-win sharing" as its corporate purpose. It focuses on high cost-performance, quality service, and collaborates with customers to expand markets and create ongoing achievements.

![JY-ZSE High Elongation Self-Adhesive Waterproofing Membrane [e]](https://great-ocean-waterproof.com/wp-content/uploads/2025/12/JY-ZSE-High-Elongation-Self-Adhesive-Waterproofing-Membrane-e2_1-300x300.webp)