EPDM Waterproofing Membrane

Our EPDM waterproofing membrane is designed for roof protection, available in thicknesses of 1.2mm, 1.5mm, 1.8mm, and 2.0mm. Each roll measures 2m x 20m and comes in colors such as black, white, gray, blue, green, and more. Surface options include bare board or single belt cloth, with construction methods involving glue and hot air welding for overlapping edges. As a manufacturer in Shandong, China, we offer this epdm rubber waterproofing solution at competitive price points. It’s also suitable for epdm sheet waterproofing applications and epdm foundation waterproofing needs, produced directly from our factory to ensure consistent quality.

Product Introduction

The EPDM waterproofing membrane is a synthetic rubber sheet designed for roof protection and general waterproofing tasks. It consists of ethylene propylene diene monomer material, which provides flexibility and resistance to environmental factors in construction settings. This membrane is typically applied to flat or low-slope roofs, ponds, and foundation areas where water barriers are needed.

Manufactured with a bare board or single belt cloth surface, the epdm membrane waterproofing comes in thicknesses of 1.2 mm, 1.5 mm, 1.8 mm, or 2.0 mm, and standard roll sizes of 2 m width by 20 m length. Available colors include black, white, gray, blue, green, and others to match project requirements. Installation involves glue adhesion and hot air welding for overlapping edges, allowing for seams that maintain integrity over time.

Technical properties vary by type, such as JL1 and JF1 models. For instance, tensile strength reaches 7.5 MPa at normal temperature and 2.3 MPa at 60°C for JL1, while elongation at break is 450% at normal temperature and 200% at -20°C. Tear strength is at least 25 kN/m for JL1, with impermeability tested at 0.3 MPa for 30 minutes without leakage. Low temperature bendability holds at -40°C for JL1.

Common in both commercial and residential builds, the epdm rubber waterproofing suits applications like green roofs or underground structures due to its non-biodegradable nature and compatibility with various substrates. It remains stable under UV exposure and temperature fluctuations, though proper edge detailing is necessary for long-term performance.

Product Specfication

Product Name | Roof protection waterproof membrane |

Thickness | 1.2mm 1.5mm 1.8mm 2.0mm |

Size | 2mx20m/roll |

Color | Black white gray blue green etc |

Surface | Bare board、single belt cloth |

Construction method | Glue and hot air welding overlapping edge |

Product Features

- High elasticity and elongation: Elongation at break ≥450% (JL1) at normal temperature and still ≥200% at -20°C, allowing the membrane to accommodate substrate movement and minor cracks without tearing.

- Good tensile and tear strength: Tensile strength ≥7.5 MPa at room temperature and ≥25 kN/m tear resistance, providing adequate mechanical durability during installation and service.

- Reliable impermeability: No leakage under 0.3 MPa water pressure for 30 minutes, suitable for standard roofing and pond lining requirements.

- Excellent low-temperature performance: Remains flexible down to -40°C (JL1) or -30°C (JF1) with no cracking, making it workable and functional in cold climates.

- Wide temperature resistance range: Maintains properties from -40°C up to normal roofing temperatures; tensile strength still reaches 2.3 MPa at 60°C.

- Long-term weather resistance: Proven resistance to UV, ozone, and oxidation, commonly used in exposed roofing applications for decades.

- Simple and secure overlapping: Overlaps joined by contact adhesive and hot-air welding, forming strong, watertight seams when properly executed.

- Multiple surface options: Available as homogeneous (bare) or reinforced with single belt cloth for improved dimensional stability and puncture resistance.

- Broad color selection: Black, white, grey, blue, green, etc., allowing aesthetic matching or heat-reflective white surfaces for cooler roofing.

Performance

item | index | ||

JL1 | JF1 | ||

tensile strength(Mpa) | normal temperature ≥ | 7.5 | 4.0 |

60°C ≥ | 2.3 | 0.8 | |

elongation at break(%) | normal temperature ≥ | 450 | 400 |

-20°C ≥ | 200 | 200 | |

tear strength (KN/m) ≥ | 25 | 18 | |

Impervious to water, no leakage for 30min | 0.3Mpa | 0.3Mpa | |

low temperature bendability (°C) | -40 | -30 | |

Applications – EPDM Waterproofing Membrane

- Flat and low-slope roofing: Applied to commercial buildings, warehouses, and residential structures for long-term water exclusion on concrete, wood, or metal decks.

- Green roof systems: Used as a root-resistant liner beneath soil and vegetation layers, supporting drainage and plant growth without degradation.

- Pond and water feature lining: Installed in decorative ponds, retention basins, and fish farms to maintain water containment under constant submersion.

- Roof repair and overlay: Laid over existing failed roofing materials to extend service life without full tear-off, bonded via adhesive or mechanical fastening.

- Foundation and plaza deck waterproofing: Placed above buried slabs or podiums to prevent water ingress into parking garages or occupied spaces below.

- Exposed architectural details: Wrapped around parapets, curbs, and penetrations where UV-stable, flexible sealing is required.

- Industrial tank and reservoir liners: Deployed in secondary containment areas for chemicals or water storage, leveraging chemical resistance and seam integrity.

Differences Between EPDM and HDPE Waterproofing Membranes

| Aspect | EPDM (Ethylene Propylene Diene Monomer) | HDPE (High-Density Polyethylene) |

|---|---|---|

| Material Type | Synthetic rubber (thermoset) | Thermoplastic polymer |

| Chemical Structure | Cross-linked rubber chains | Linear polyethylene chains |

| Primary Use | Exposed roofing, ponds, flexible substrates | Below-grade foundations, tunnels, pre-applied concrete bonding |

| Installation Method | Glued seams, hot-air or tape welding, mechanical fastening | Pre-laid self-adhesive, reacts with wet concrete |

| Bonding to Concrete | Mechanical or adhesive only | Chemical full-surface bond (≥1.0 N/mm peel) |

| Self-Healing | None (requires patches) | Yes – minor damage seals in wet pour |

| UV Resistance | Excellent (long-term exposure) | Limited (requires cover) |

| Low-Temp Flexibility | -40°C to -45°C (no cracks) | -25°C (adhesive layer -23°C) |

| Tensile Strength | 7–10 MPa | ≥19 MPa |

| Elongation at Break | 300–500% | ≥400% |

| Seam Integrity | Welded or glued (potential weak point) | Self-adhesive lap tape or welded (80–100 mm) |

| Hydrostatic Resistance | Depends on seam quality | 0.8 MPa / 4h – no channeling |

| Service Life (Buried) | 30–40 years | 50+ years |

| Repair Method | Patch with uncured EPDM + adhesive | Self-heals during concrete pour |

| Typical Thickness | 1.1–2.3 mm | 1.2–2.0 mm |

Key Practical Distinctions

- EPDM works best in post-applied, flexible, or exposed conditions where movement and UV are factors.

- HDPE is engineered for pre-applied, rigid concrete structures needing permanent, maintenance-free waterproofing with zero water migration risk.

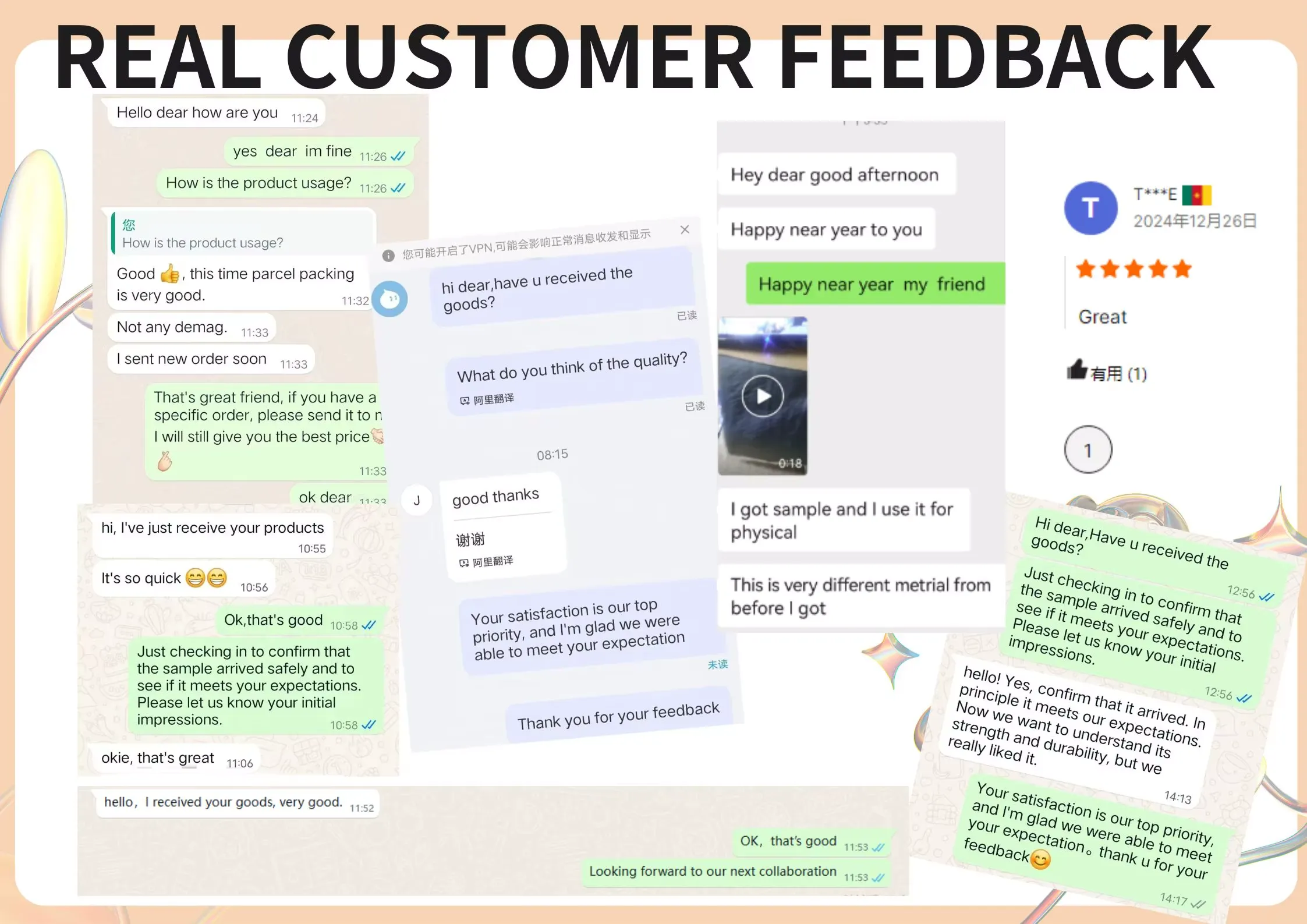

Customer Reviews

Robert T., Roofing Contractor – Chicago, USA "Used the 1.5 mm black EPDM on a 25,000 sq ft flat commercial roof. The hot-air welded seams held tight through two winters down to -25 °C. No ponding leaks after 14 months, and the roll size (2 m × 20 m) reduced waste on the layout."

Sophie L., Landscape Designer – Lyon, France "Specified the white 1.2 mm membrane for a 600 sqm green roof system. The -40 °C bendability let us fold around upstands without cracking in January. Root barrier layer stayed intact after one full growing season; drainage tests still show zero water backup."

Tan Wei, Maintenance Supervisor – Singapore "Applied the 1.8 mm gray EPDM to repair an old concrete pond liner. Glue-and-weld overlaps sealed in 32 °C humidity without bubbling. Fish stocking resumed after 48 hours; water level has stayed constant for 9 months."

Carlos M., Project Engineer – Santiago, Chile "Installed the reinforced 2.0 mm version on a low-slope warehouse roof. The single belt cloth gave enough tear resistance for foot traffic during HVAC placement. UV exposure for 11 months shows no chalking or shrinkage on the white surface."

Hiroshi K., Facility Manager – Osaka, Japan "Retrofitted the 1.5 mm black sheet over an existing built-up roof. The 450% elongation handled thermal movement on steel decking. Annual inspections after 18 months confirm seams at 0.3 MPa impermeability with no lifting."

FAQ

Q: What is the expected service life of the EPDM membrane? A: In protected or buried applications, 25–35 years is typical with proper installation. Exposed roofing can reach 20–30 years depending on UV intensity and maintenance.

Q: Can it be installed in cold weather? A: Yes, down to -10 °C for adhesive work and -5 °C for hot-air welding. Below that, use tents or heaters to keep materials above freezing.

Q: Is the membrane compatible with bitumen substrates? A: Direct contact with fresh bitumen should be avoided. Use a separation layer (geotextile or polyethylene sheet) if overlaying old asphalt.

Q: How are seams sealed? A: Overlaps are joined with contact adhesive followed by hot-air welding at 450–500 °C. Seam peel tests should exceed 15 N/cm when done correctly.

Q: Does it require a root barrier for green roofs? A: The standard EPDM is not root-resistant. Pair it with a dedicated root-barrier sheet or use our root-resistant variant if specified.

Q: What thickness should I choose? A: 1.2 mm for light-duty roofing/ponds; 1.5 mm for standard commercial roofs; 1.8–2.0 mm for high-traffic or heavy ballast systems.

Q: Can it be walked on after installation? A: Light foot traffic is fine once seams are cured. Use walk pads under heavy equipment or frequent access routes.

Q: Is white EPDM cooler than black? A: Yes—white reflects 70–80 % of solar radiation vs. 5–10 % for black, reducing roof surface temperature by 20–30 °C in summer.

Q: How do I repair a puncture? A: Clean the area, apply uncured EPDM patch with primer and seam tape. For larger damage, use a full cover patch welded on all sides.

Q: Will it work on a metal roof with rust? A: Rust must be removed and primed first. Loose rust will compromise adhesion; consider a full deck replacement if corrosion is extensive.

About Our Factory

Great Ocean Waterproof Technology Co., Ltd. (formerly Weifang Great Ocean New Waterproof Materials Co., Ltd.) is located in Taitou Town, Shouguang City—the center of China’s largest waterproofing materials production base. Established in 1999, the company has grown into a high-tech enterprise integrating research, development, manufacturing, and sales of professional waterproofing systems.

The 26,000-square-meter factory complex houses multiple advanced production lines capable of producing rolls, sheets, and liquid coatings at scale. These lines support the full range of products, including the EPDM Waterproofing Membrane, as well as PVC, TPO, CPE, self-adhesive HDPE, polymer-modified bitumen, root-resistant membranes, and various polyurethane and cementitious coatings.

With a strong technical team and complete in-house testing facilities, the factory maintains stable quality control throughout production. All materials, including the EPDM membrane, meet national standards and hold relevant certifications. Products are distributed across more than 20 provinces in China and exported to several international markets, backed by consistent performance records and reliable delivery.

![JY-ZPU Self Adhered Membrane Self-Adhesive Polymer Waterproof Membrane [PY]](https://great-ocean-waterproof.com/wp-content/uploads/2025/12/JY-ZPU-Self-Adhered-Membrane-Self-Adhesive-Polymer-Waterproof-Membrane-PY_1-300x300.webp)