Asphalt Self Adhesive Waterproof Tape

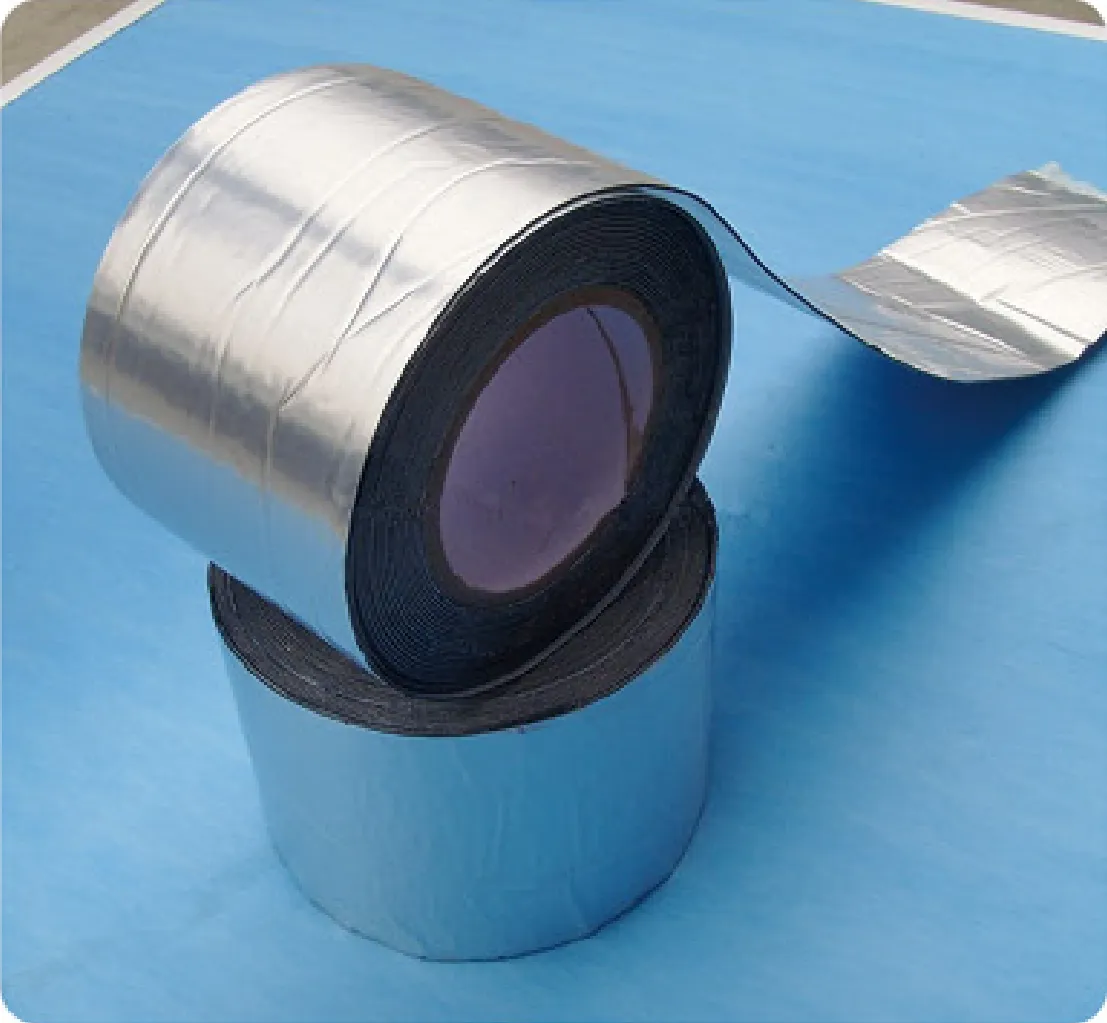

Asphalt Self Adhesive Waterproof Tape is a composite-based material designed for roof leak repairs, featuring a self-adhesive layer for easy application. The surface is coated with aluminum foil or similar options, while the bottom includes release paper for protection. Produced in our China factory as a reliable manufacturer, this tape offers solid adhesion and flexibility, ensuring durable installation without pollution. Available in small stock quantities at competitive price with quick delivery; usage adapts to specific site conditions.

Product Introduction

The Asphalt Self Adhesive Waterproof Tape from Great Ocean Waterproof is a rollable sealing material designed for waterproofing applications in construction and repair. It uses polymer-modified asphalt as the base layer, reinforced with a polyester or fiberglass mat for added structure. The top surface is covered with options like polyethylene film, fine sand, or aluminum foil, while the bottom features a self-adhesive layer protected by a release film.

This tape provides reliable adhesion and flexibility, allowing it to conform to surfaces during cold application without additional adhesives. It combines rubber-like pliability with asphalt's weather resistance, making it suitable for sealing joints, roofs, and leaks in various conditions. Construction is straightforward, with no need for heat or solvents, and it minimizes environmental impact from pollutants.

Available in widths such as 5cm, 10cm, or custom sizes, it supports uses like roof cracks, gutters, and general moisture barriers, with properties including high elongation for expansion handling and self-healing against minor punctures. For specific projects, application methods can be adjusted based on site requirements.

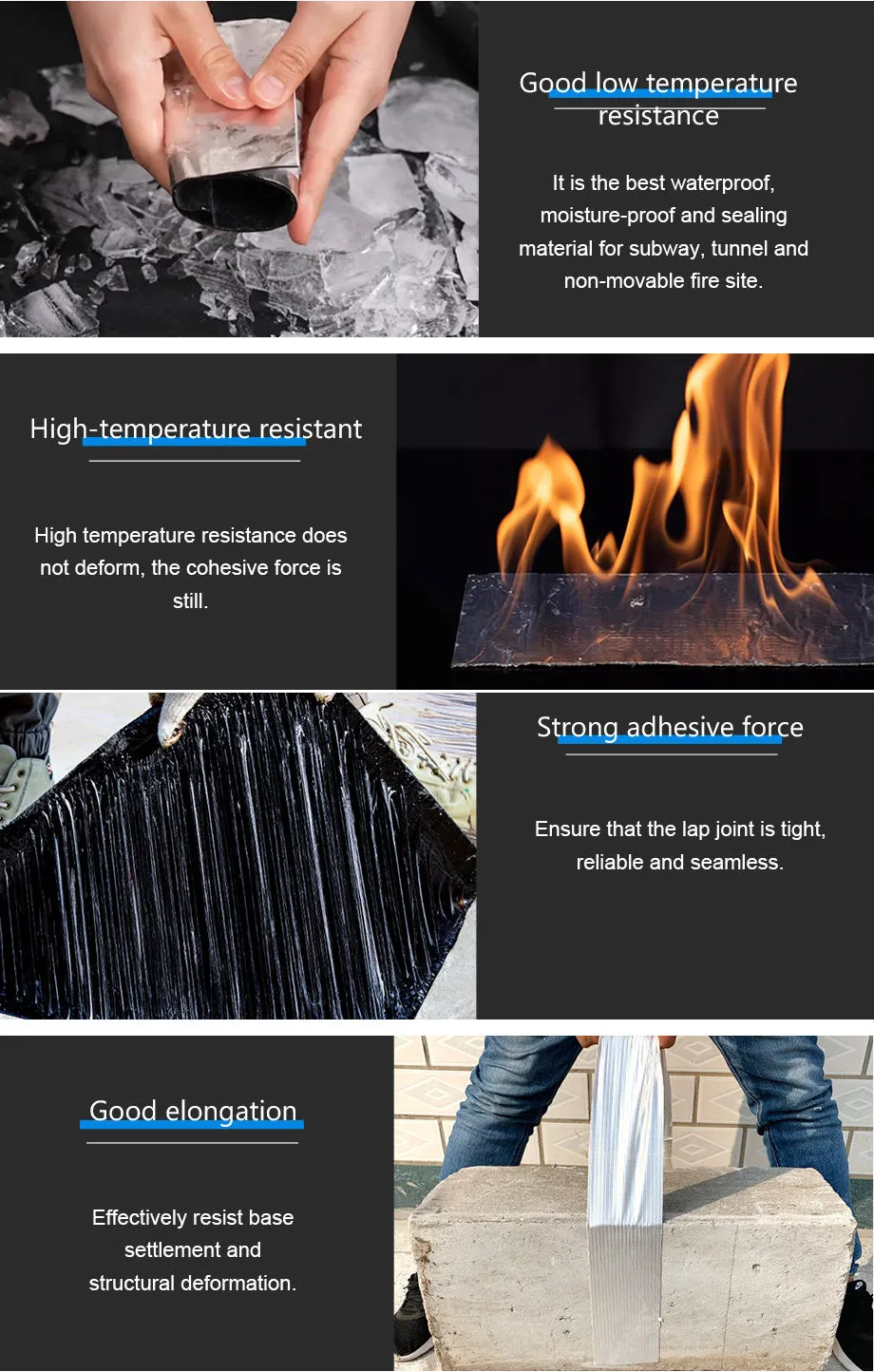

Product Features

- Waterproof Performance: The Asphalt Self Adhesive Waterproof Tape offers an elongation rate exceeding 1000%, with strong resilience. This allows it to accommodate substrate deformation without cracking, preventing leaks. It provides adhesion stronger than the material itself, ensuring seamless integration with surfaces and no separation. The tape forms a continuous waterproof layer without boundaries. It also features self-healing properties, similar to skin recovery, where it can repair itself from punctures or foreign objects, maintaining impermeability.

- Long Service Life: The tape resists high temperatures, low temperatures, and corrosion. It has been used in extreme UV conditions at Antarctic research stations for seven years without degradation. Testing shows that one year of exposure in Antarctica equates to ten years in Asian regions in terms of aging.

- Safe and Simple Construction: Due to its strong self-adhesion, the tape is easy to apply, even for non-professional workers who can learn from a demonstration. It requires cold application without additional adhesives—just overlap and stick—for high first-time success rates. This saves time and labor while ensuring safety and reliability.

- Environmental and Economic Benefits: The tape produces no toxic odors or pollution during application, making it safe and eco-friendly. It serves as a cost-effective solution for preventing leaks in construction projects.

Applications

- Roofing and Structural Waterproofing: This tape is used for repairing and sealing roofs, including steel structures, where it handles expansion joints and stressed areas. It provides a continuous barrier against water ingress in building roofs and similar surfaces.

- Marine and Vessel Sealing: Suitable for sealing ship hatches, decks, and cabin enclosures. The self-adhesive property allows application in marine environments without heat, reducing risks in confined spaces.

- Basement and Underground Waterproofing: Applied in basements and underground structures to prevent moisture penetration. It adheres to concrete and other substrates, forming a seal in areas prone to dampness.

- Bathroom and Interior Waterproofing: Used in bathrooms and wet areas for sealing around fixtures and walls. The material's flexibility accommodates minor movements without compromising the seal.

- Vertical Surfaces and Facades: Can be applied to vertical walls and facades for waterproofing. It sticks without additional tools, making it practical for elevated or irregular surfaces.

- Pipelines and Infrastructure: Effective for sealing non-heated pipelines, bridges, and complex environments. It withstands varying conditions but is not recommended for hot pipelines due to temperature limitations.

- Fire-Restricted Environments: Ideal for projects where open flames or heat sources are prohibited, such as chemical storage areas or sensitive facilities, as it requires only cold application.

Customer Reviews

John from the United States

I used this tape to seal some cracks in my garage roof after a heavy rain season. It stuck well without needing extra tools, and so far, it's held up through a few storms without any leaks showing up. The roll was easy to cut and apply, though I had to make sure the surface was clean first. Overall, it did what I needed for the price.

Emma from the United Kingdom

Applied this to the seams around my greenhouse windows where water was seeping in. The self-adhesive backing made installation straightforward, even in cooler weather. It's been a couple of months, and the seal seems solid—no more drips inside. I appreciate that it didn't require heating or messy glues, which suited my DIY setup.

Liam from Australia

We get a lot of sun and occasional downpours here, so I tried this tape on my shed's metal roof joints. It adhered properly after pressing it down, and it hasn't peeled off despite the heat. The flexibility helped with the uneven surfaces. Not the thickest material I've used, but it stopped the leaks effectively for my needs.

Sophie from Canada

In our cold winters, I needed something for sealing basement window frames against moisture. This tape went on easily without cracking in the low temperatures, and it's prevented water from getting in during thaws. The length per roll was sufficient for multiple spots. It's a practical option if you're looking for a no-fuss waterproofing fix.

Hans from Germany

I applied it to repair seals on my balcony railing connections where rain was causing rust issues. The adhesion was reliable on concrete and metal, and it conformed to the shapes without bubbles. After several weeks of variable weather, it's still in place. Good for small-scale repairs, though I'd test compatibility with your surfaces first.

Comparison to Silicone Sealants

The Asphalt Self Adhesive Waterproof Tape and silicone sealants both serve as waterproofing solutions but differ in composition, application, and performance based on specific use cases. Below is a side-by-side comparison drawing from industry insights.

| Aspect | Asphalt Self Adhesive Waterproof Tape | Silicone Sealants | Notes |

|---|---|---|---|

| Material Composition | Typically consists of polymer-modified asphalt with reinforcements like polyester or fiberglass, backed by a self-adhesive layer. | Made from silicone polymers, often available in tube form for caulking. | Asphalt tapes are more akin to butyl tapes in flexibility and adhesion, while silicones provide a different chemical resistance. |

| Application Method | Applied cold as a roll; self-adhesive, requires clean surface and pressure for bonding; no tools needed beyond cutting. | Applied via caulking gun; requires curing time (hours to days) and may need primers on some surfaces. | Tape is simpler for DIY and quick fixes, especially in fire-restricted areas, but silicone allows for filling irregular gaps. |

| Adhesion and Compatibility | Strong on porous or uneven surfaces like concrete, metal, and asphalt; may not bond well to silicone-treated materials. | Versatile on glass, metal, and plastics; poor adhesion to asphalt or bituminous surfaces without preparation. | Compatibility checks are essential; asphalt tape excels on roofing materials where silicone might peel. |

| Flexibility and Elongation | High elongation (often over 1000%), accommodates substrate movement without cracking. | Moderate flexibility (100-300% elongation), but can become brittle over time in extreme conditions. | Tape handles expansion joints better, while silicone suits static seals. |

| Durability and Weather Resistance | Resists UV, temperature extremes (-40°F to 200°F), and chemicals; self-healing for minor punctures; longer lifespan in outdoor exposures. | Excellent UV and moisture resistance, but may degrade faster under constant ponding water or mechanical stress. | Asphalt tape often provides longer-term seals in roofing; silicone is preferred for flat roofs with standing water. |

| Waterproofing Effectiveness | Forms a continuous barrier; excellent for seams and joints, but less ideal for high-moisture immersion like bathrooms. | Superior in constant wet areas due to non-porous nature; effective for gaps but can shrink during curing. | Neither is universally better; tape may underperform in prolonged moisture compared to silicone. |

| Cost and Availability | Generally cost-effective for covering larger areas; available in rolls of various widths. | Often cheaper per unit but requires more labor; widely available in hardware stores. | Tape saves on application time, potentially reducing overall costs for repairs. |

| Limitations | Not suitable for high-heat applications or where frequent removal is needed; can be messier if not applied correctly. | Curing time needed; less effective as an adhesive compared to sealants designed for bonding; potential for mold in some formulas. | Choice depends on the project—tape for quick, flexible seals; silicone for precise, gap-filling work. |

Overall, the choice between the two depends on the specific requirements, such as surface type and environmental conditions, with no one option being inherently superior across all scenarios.

Frequently Asked Questions (FAQ)

What surfaces can the Asphalt Self Adhesive Waterproof Tape be applied to? The tape adheres to a variety of surfaces including concrete, metal, asphalt, wood, and some plastics. It's best suited for clean, dry, and non-porous materials. Always test a small area first to ensure compatibility, as it may not bond well to silicone-treated or oily surfaces.

How do I apply the tape? Clean the surface thoroughly to remove dust, grease, or moisture. Peel off the release liner, press the tape firmly onto the area, and use a roller or hand pressure to ensure full contact. Overlap seams by at least 2 inches for better sealing. No heat or additional adhesives are required, making it suitable for cold application.

How long does the tape last once applied? Under normal conditions, it can last 5-10 years or more, depending on exposure to UV, temperature fluctuations, and mechanical stress. In extreme environments like high heat or constant moisture, lifespan may be shorter. Regular inspections are recommended for outdoor uses.

Is the tape fully waterproof and can it handle standing water? It provides a reliable waterproof barrier for seams, cracks, and joints, but it's not designed for prolonged immersion or areas with constant ponding water. For such cases, it works best as part of a larger waterproofing system.

Can the tape be removed or repositioned after application? Once fully adhered, removal can be difficult and may leave residue. It's intended for permanent fixes. If repositioning is needed shortly after application, it can be done carefully, but adhesion strength increases over time.

What temperatures can the tape withstand? It performs in temperatures from -40°F to 200°F (-40°C to 93°C). Application is recommended between 40°F and 100°F (4°C to 38°C) for optimal adhesion. In very cold conditions, warming the tape slightly can help.

Is this tape environmentally friendly and safe to use? The tape produces no toxic fumes during application and is free from solvents. It's considered low-VOC, but proper ventilation is advised in enclosed spaces. Disposal should follow local regulations for asphalt-based materials.

What sizes and thicknesses are available? Common widths include 2 inches, 4 inches, and 6 inches, with lengths up to 50 feet per roll. Thickness typically ranges from 1mm to 2mm. Custom sizes may be available depending on the supplier.

How does it compare to other waterproofing options like caulk or liquid sealants? Unlike caulk, which requires curing time and a gun for application, this tape is ready-to-use and self-adhesive for quicker installation. It offers higher flexibility for moving surfaces but may not fill deep gaps as effectively as liquid options.

Can it be used indoors, such as in bathrooms? Yes, it's suitable for indoor areas like bathrooms for sealing around tubs, showers, or tiles. Ensure the surface is dry before application, and it can handle humidity well, though it's not meant for direct submersion.

About Our Factory

Great Ocean Waterproof Technologies Co., Ltd. (formerly Weifang Great Ocean New Waterproof Materials Co., Ltd.) is located in the government seat of Taitou Town, Shouguang City, which is recognized as China's largest base for waterproof materials. Established in 1999, the company operates as a high-tech waterproofing specialist integrating research, production, and sales.

The factory covers an area of 26,000 square meters. Over the years, it has developed multiple advanced production lines for rolls, sheets, and coatings at a domestic leading level. Key products include polyethylene polypropylene (polyester) polymer waterproof rolls, polyvinyl chloride (PVC) waterproof rolls, thermoplastic polyolefin (TPO) waterproof rolls, high-speed rail-specific chlorinated polyethylene (CPE) waterproof rolls, polymer polypropylene self-adhesive waterproof rolls, non-asphalt-based reactive pre-laid polymer self-adhesive membrane waterproof rolls, strong cross-laminated film polymer reactive adhesive waterproof rolls, protective drainage boards, elastomeric/plastomeric modified asphalt waterproof rolls, asphalt-based self-adhesive waterproof rolls, polymer-modified asphalt root-resistant waterproof rolls, metal-based polymer root-resistant waterproof rolls, root-resistant polymer polyethylene propylene (polyester) waterproof rolls, root-resistant polyvinyl chloride PVC waterproof rolls, single-component polyurethane waterproof coatings, dual-component polyurethane waterproof coatings, polymer cement (JS) composite waterproof coatings, water-based (951) polyurethane waterproof coatings, polyethylene propylene (polyester) special dry powder adhesives, cement-based permeable crystalline waterproof coatings, spray quick-setting rubber asphalt waterproof coatings, non-curing rubber asphalt waterproof coatings, exterior wall transparent waterproof gels, high-elasticity liquid roll waterproof coatings, self-adhesive asphalt waterproof tapes, butyl rubber self-adhesive tapes, and dozens of other varieties.

The company maintains strong technical capabilities with a team of professional technicians, advanced equipment, comprehensive testing instruments, and stable product quality, certified by national authoritative testing institutions. It has earned the "Comprehensive Quality Management Compliance" title from the Ministry of Agriculture, passed quality assurance system certification, and received designations such as "National Authoritative Testing Qualified Product" from the China Quality Inspection Association, Shandong Province's "Industrial Construction Product Filing Certificate," "Industrial Product Production License," and CE certification.

Emphasizing contract adherence and credibility, the company's products are sold in over 20 provinces and regions across China and exported to multiple countries and regions overseas, receiving positive feedback from users.

Great Ocean Waterproof Technologies Co., Ltd. employs modern operational and management mechanisms, guided by the corporate spirit of "integrity, pragmatism, and innovation," and the purpose of "win-win sharing." It focuses on high cost-performance, quality service, and collaborative market expansion with partners to achieve ongoing progress.