ציפוי פוליאוריטן עמיד למים

חוו הגנה אולטימטיבית ללא ממסים עם ציפוי האיטום הפוליאוריטני הטוב ביותר מבית Great Ocean. תיהנו מיתרונות גגות נוזליים ללא ריחות - אידיאלי לאתרים מוגבלים. הנוסחה שלנו, המיושמת בקור ותכולת מוצקים גבוהה, יוצרת קרום חלק ואטום במהירות, עם עמידות מעולה בפני אגמים, הגנה מפני קרינת UV ועמידות מפני דליפות, בלאי, קורוזיה ופגיעות בליה. תואם לגגות קיימים (שטוחים, משופעים, כיפתיים) - אפילו לגגות פגומים.

ציפוי פוליאוריטן עמיד למים למכירה

בעוד שדף זה מציג את מערכות הליבה שלנו, Great Ocean Waterproof מציעה תיק מקיף של פתרונות איטום מתקדמים שנועדו לענות על דרישות בנייה מגוונות. אנו מחויבים לספק את החומר המתאים לכל פרויקט. אם יש לכם שאלות לגבי מפרטי מוצר ספציפיים, אפשרויות התאמה אישית, או שאתם זקוקים למחיר תחרותי לציפוי איטום מפוליאוריטן, אל תהססו לפנות אלינו. צרו קשר עם הצוות שלנו בכל עת - אנו מוכנים לסייע לכם ולהבטיח תשובה תוך שעתיים.

יתרונות איטום פוליאוריטן

איטום פוליאוריטן מציע מגוון יתרונות מעולים, מה שהופך אותו לבחירה אידיאלית להגנה על מבנים מפני נזקי לחות. להלן, נחקור יתרונות עיקריים, כולל יעילות אנרגטית, תכונות נוגדות פחמן ועוד, המבטיחות ביצועים ארוכי טווח וחיסכון בעלויות.

יעילות אנרגטית

פוליאוריטן ציפויים עמידים למים תורמים ליעילות אנרגטית על ידי מתן בידוד תרמי מעולה, הפחתת העברת חום דרך גגות וקירות. זה עוזר לשמור על טמפרטורות יציבות בתוך הבית, להפחית את עלויות החימום והקירור בבניינים. תכונותיהם המחזירות אור יכולות גם למזער את צריכת החום הסולארי, ולתמוך בשיטות בנייה בנות קיימא וידידותיות לסביבה.

אנטי-קרבונציה

עם יכולות חזקות נגד קרבונציה, איטום פוליאוריטן מונע חדירת פחמן דו חמצני למשטחי בטון, דבר שעלול להוביל לקורוזיה של פלדת חיזוק. מחסום מגן זה מאריך את תוחלת החיים של מבנים בסביבות עירוניות או תעשייתיות בהן החשיפה ל-CO2 גבוהה, תוך שמירה על שלמות מבנית לאורך זמן.

עמידות בלחץ מים

ציפויים אלה מצטיינים בעמידות בפני לחץ מים, ויוצרים קרום אטום העומד בפני לחץ הידרוסטטי ממי תהום או גשמים כבדים. אידיאליים למרתפים ויסודות, הם מונעים חדירת מים אפילו בתנאי לחץ גבוה, ומבטיחים חללים פנימיים יבשים ובטוחים מבלי להתפשר על גמישות.

גישור סדקים והידבקות

מערכות פוליאוריטן מספקות גישור יוצא דופן על סדקים, מכסה סדקים זעירים ומאפשרות תנועות מבניות ללא כשל. ההידבקות החזקה שלהן נקשרת בצורה חלקה למצעים שונים כמו בטון, מתכת ועץ, ומבטיחות איטום אמין גם על משטחים לא אחידים או פגומים, ומפחיתות את הסיכון לדליפות.

גְמִישׁוּת

איטום פוליאוריטן, המציע גמישות והתארכות גבוהות, נשאר גמיש בטווח טמפרטורות רחב, ומונע סדקים עקב התפשטות או התכווצות תרמית. יכולת הסתגלות זו הופכת אותו למתאים לסביבות דינמיות, כגון גגות או גשרים, שבהן תנועה נפוצה.

יישום קל

היישום פשוט ורב-תכליתי, עם פורמולות נוזליות הניתנות לרסס, למריחה או לגלגול, ויוצרות ממברנות חלקות ללא חיבורים. זמני ייבוש מהירים ואפשרויות דלי ריח מאפשרים הפרעה מינימלית, מה שהופך אותו לנגיש הן לאנשי מקצוע והן לפרויקטים של "עשה זאת בעצמך".

עמידות ואריכות ימים

ציפויי פוליאוריטן, הידועים בעמידותם, עמידים בפני קרני UV, כימיקלים, שחיקה ופגיעות מזג אוויר, ומספקים הגנה ארוכת טווח שיכולה להחזיק מעמד 10-20 שנים או יותר עם תחזוקה נאותה. עמידות זו ממזערת את צורכי התיקון, ומציעה פתרונות חסכוניים ליישומים תובעניים.

הצטרפו למועדון שלנו

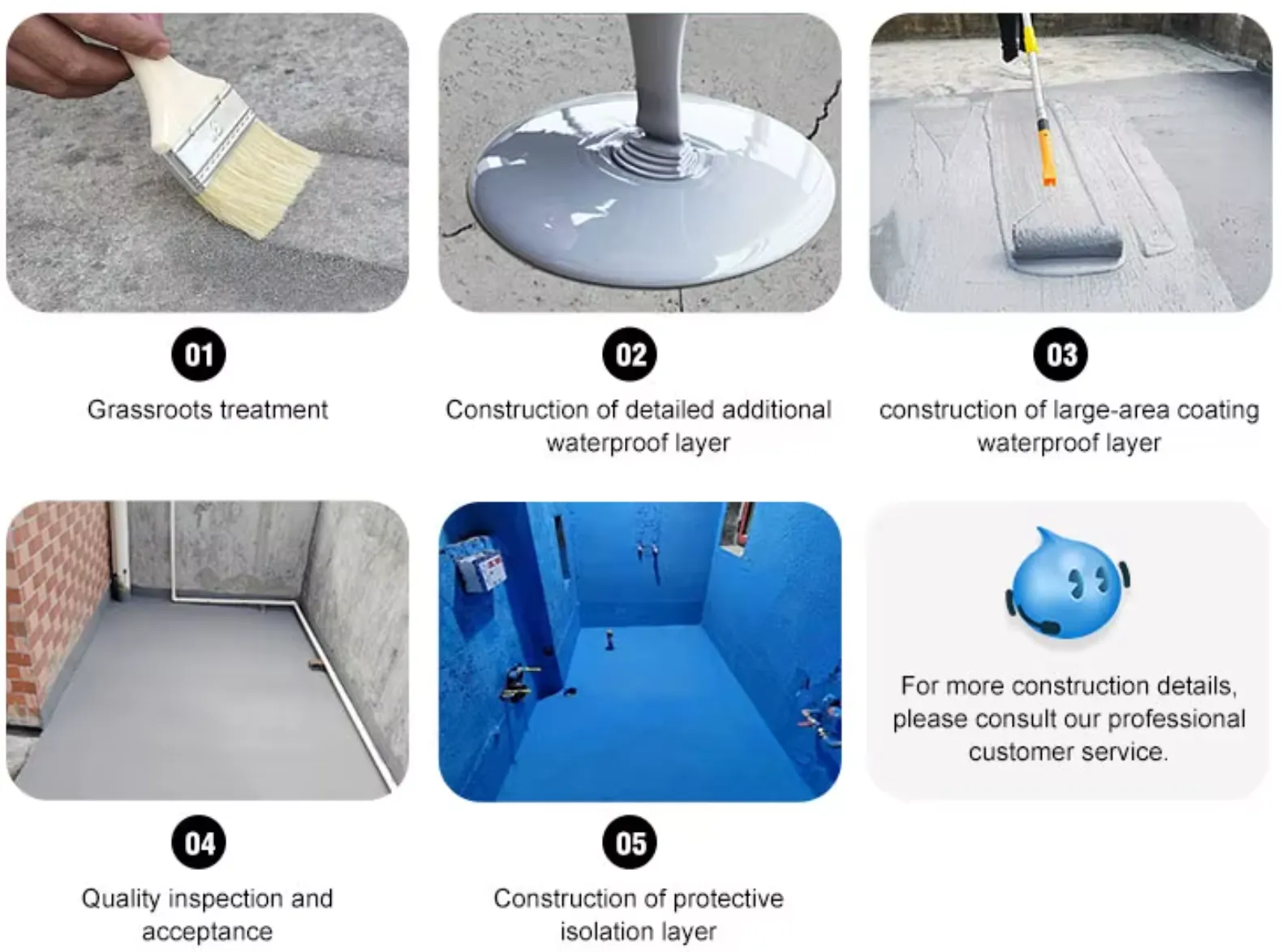

כיצד למרוח ציפוי פוליאוריטן עמיד למים

פוליאוריטן הוא אחד מפתרונות האיטום העמידים והגמישים ביותר שקיימים, והוא מועדף בזכות יכולתו לגשר על סדקים ולעמוד בפני התפשטות תרמית. כדי להבטיח איטום עמיד לאורך זמן, יישום נכון הוא קריטי.

בעוד שחומר זה רב-תכליתי מספיק עבור מצעים שונים כמו עץ ומתכת, הוא מתפקד בצורה הטובה ביותר כאשר הוא מיושם על משטחים מינרליים נקבוביים. באופן ספציפי, באמצעות חומר איכותי ציפוי פוליאוריטן למים לבטון מבטיח הידבקות מעולה ויוצר ממברנה חלקה, דמוית גומי, המגנה על המבנה מפני נזקי מים, קרני UV ותנועת הולכי רגל.

להלן מדריך שלב אחר שלב להשגת גימור מקצועי.

1. הכנת פני השטח

השלב החשוב ביותר הוא ההכנה. המשטח חייב להיות נקי, יבש ויציב.

-

ניקיון: הסירו את כל הפסולת הרופפת, האבק, השמן, השומן או הציפויים הקודמים. עבור בטון, ייתכן שיהיה צורך בשטיפה בלחץ גבוה או ליטוש כדי לפתוח את הנקבוביות.

-

בדיקת לחות: ודאו שהתשתית יבשה לחלוטין. לחות כלואה עלולה לגרום לציפוי לבעבע או להתפורר בהמשך.

-

לְתַקֵן: מלאו כל סדקים, חללים או חלת דבש בחומר איטום פוליאוריטן מתאים או מלט תיקון לפני תחילת היישום העיקרי.

2. הכנה

לעולם אל תוותרו על הפריימר. פריימר ייעודי משמש כחומר מקשר בין המצע לציפוי.

-

יש למרוח את הפריימר באופן שווה באמצעות רולר או מברשת.

-

יש לתת לו להתייבש לפי הוראות היצרן (בדרך כלל 4-6 שעות) עד שהוא דביק אך לא רטוב.

3. עבודת פרטים (פילטים ופינות)

לפני ביצוע עבודות הרצפה הראשית או הגג, יש לחזק את נקודות התורפה.

-

יש למרוח שכבה עבה של פוליאוריטן על כל הפינות הפנימיות, צמתים בין קירות לרצפה, וסביב ניקוזים או צינורות.

-

הטמיעו בד גיאוטקסטיל מחזק לתוך הציפוי הרטוב בצמתים אלה כדי למנוע קרעים עתידיים.

4. מריחת השכבה הראשונה

לאחר שהפריימר מוכן והפרטים אטומים:

-

לְעַרְבֵּב: ערבבו היטב את ציפוי הפוליאוריטן (באמצעות מערבל מכני במהירות נמוכה) כדי להבטיח מרקם הומוגני.

-

לִפְנוֹת: שפכו את הציפוי על המשטח ומרחו אותו באופן שווה באמצעות מגב, כף מחורצת או רולר בעל שכבה קצרה.

-

כיסוי: ודאו שאתם עומדים בעובי המומלץ (בדרך כלל 0.5 מ"מ עד 1 מ"מ לשכבה). אין למרוח את השכבה דק מדי.

5. מריחת שכבת הציפוי העליונה

רוב המערכות דורשות שתי שכבות לעמידות מרבית.

-

יש להמתין לייבוש השכבה הראשונה (בדרך כלל 12-24 שעות). יש למרוח עליה מעט דביקה אך ניתנת להליכה עליה, על מנת להבטיח קשר כימי בין השכבות.

-

יש למרוח את השכבה השנייה בכיוון צולב (בניצב) לשכבה הראשונה. כך יוודאו שלא יהיו חורים או נקודות חסרות.

6. ריפוי

יש לאפשר למערכת הסופית להתייבש לחלוטין - בדרך כלל 48 עד 72 שעות - לפני מתן אפשרות לתנועה כבדה של הולכי רגל או בדיקת מים.

יישומים של איטום פוליאוריטן

פתרונות איטום מפוליאוריטן מציעים הגנה רב-תכליתית על פני משטחים וסביבות שונות, ומבטיחים עמידות ארוכת טווח מפני לחות, סדקים וגורמי לחץ סביבתיים. הניסוחים המתקדמות שלנו, כולל אפשרויות על בסיס מים, מספקים מחסומים חלקים המותאמים לתנועות מבניות תוך שמירה על ביצועים ידידותיים לסביבה.

מערכות קירוי

עבור גגות החשופים למזג אוויר קשה, א ציפוי פוליאוריטן עמיד למים לגג מספק עמידות וגמישות מעולות לקרינת UV, ומונע דליפות על מבנים שטוחים, משופעים או מכוסים. הוא אידיאלי הן להתקנות חדשות והן לתיקונים, תואם לחומרים קיימים כמו ביטומן או מתכת.

משטחי עץ

הגנה על דקים מעץ, גדרות או ריהוט גן מפני ריקבון ונזקי מים היא קלה לחלוטין בעזרת ציפוי פוליאוריטן עמיד למים לעץיישום מיוחד זה יוצר שכבה נושמת אך אטומה, המשפרת את אורך החיים מבלי לשנות את המראה הטבעי.

מרתפים ויסודות

באזורים מתחת לפני הקרקע הנוטים לחלחול מי תהום, ציפויי פוליאוריטן יוצרים מחסומי לחות חזקים, העמידים בפני לחץ הידרוסטטי וצמיחת עובש, ומעניקים חללים יבשים ובטוחים.

גגות ירוקים ואדניות

פרויקטים ידידותיים לסביבה נהנים ממערכות פוליאוריטן עמידות לשורשים התומכות בצמחייה תוך הגנה על מבנים בסיסיים מפני חדירת מים והצטברות מים.

רצפות תעשייתיות ומסחריות

עבור אזורים בעלי תנועה רבה כמו מחסנים או חניונים, ציפויים אלה מציעים הגנה עמידה בפני שחיקה מפני כימיקלים, שמנים ועומסים כבדים, ומאריכים את חיי המשטח.

אזורים רטובים בבניינים

חדרי אמבטיה, מטבחים ובריכות דורשים פתרונות ייבוש מהיר; ציפוי פוליאוריטן איטום על בסיס מים מצטיין כאן, ומספק יישום חסר ריח וגימור חלק העומד בתקני היגיינה.

בין אם לשימוש ביתי, מסחרי או תעשייתי, מוצרי איטום הפוליאוריטן של Great Ocean מבטיחים הגנה אמינה וחסכונית המותאמת לצרכים הספציפיים שלכם. צרו קשר לקבלת המלצות מותאמות אישית!

מקרי בוחן של יישומים

מקרה בוחן 1: איטום גגות של מבנים מסחריים בשנגחאי

סקירת הפרויקט: קומפלקס מסחרי גדול בשנגחאי התמודד עם דליפות חוזרות ונשנות בגג השטוח שלו עקב גשמים עזים, סדקים בהתפשטות תרמית וזיהום עירוני. שטח הגג של 5,000 מ"ר דרש פתרון חזק להתמודדות עם שינויי מזג אוויר קיצוניים.

אֶתגָר: קרום הביטומן הקיים התדרדר במהירות, מה שהוביל לחדירת מים תכופה, נזקים פנימיים ועלויות תחזוקה גבוהות במהלך עונות המונסון. תנודות טמפרטורה גרמו לסדקים, וריחות ממסים הוגבלו באזור המאוכלס בצפיפות.

פִּתָרוֹן: יישם ציפוי עמיד למים מפוליאוריתן כפול JY-DPU ליצירת ממברנה גמישה וחלקה. הנוסחה בעלת ריכוז מוצקים גבוה, שנמרחה בקור, הבטיחה אי פליטות ממס, בעוד שגמישות מעולה אפשרה תנועות מבניות. התמיכה הטכנית כללה הנחיות התקנה מותאמות אישית להידבקות אופטימלית על המצע המיושן.

תוצאות: לא דווח על דליפות לאחר שנתיים, עם עמידות משופרת לקרינת UV וסבילות למים בולמים שהאריכו את תוחלת החיים של הגג ב-10+ שנים. הייבוש המהיר של 24 שעות צמצם את זמן ההשבתה, חסך ללקוח בעלויות תיקון וזכה לשבחים על ביצועים ידידותיים לסביבה בסביבה עירונית עמוסת תנועה.

מקרה בוחן 2: איטום מרתפים עבור פיתוח מגורים בבייג'ינג

סקירת הפרויקט: מגדל מגורים חדש בבייג'ינג דרש איטום אמין לחניונים תת-קרקעיים ולמרתפים, שכיסו מעל 10,000 מ"ר הנוטים לחלחול מי תהום ולחץ אדמה.

אֶתגָר: מפלס מי תהום גבוה, לחות מתמדת ושקיעת מבנים סיכנו הצפות, צמיחת עובש וקורוזיה של חיזוקים, מה שסיבך את העמידה בתקני בנייה ירוקה באקלים לח.

פִּתָרוֹן: השתמשתי בציפוי אטום למים מפוליאוריתן JY-951 עבור יישום דל תרכובות אורגניות נדיפות (VOC) וללא ריח. המערכת החד-רכיבית הובראה על קירות ורצפות בטון, ויצרה מחסום אטום בעל הידבקות מצוינת ועמידות בפני שורשים באזורים ירוקים סמוכים. מדריכי יישום מפורטים הבטיחו תאימות עם חומרים קיימים.

תוצאות: המרתפים נותרו יבשים לחלוטין לאורך עונות גשם מרובות וחורפים קשים, ומנעו עובש וקורוזיה. הפרויקט עמד בתקני ההסמכה הסביבתית, כאשר היזם ציין הפחתה בזמן העבודה בתקן 30% הודות לייבוש מהיר וקלות שימוש, בנוסף לעמידות ארוכת טווח בפני פגעי מזג אוויר וחשיפה לכימיקלים.

מקרי בוחן של יישומים

ציפויי איטום וממברנות מפוליאוריטן מוערכים באמצעות תקני ASTM שונים כדי להבטיח שהם עומדים בקריטריוני ביצועים של עמידות, גמישות ועמידות למים. אלה כוללים מפרטים לחומרים עצמם ושיטות בדיקה לתכונות מפתח. להלן סקירה מקיפה המבוססת על הנחיות ASTM מבוססות, תוך התמקדות באלו החלות ישירות או הנפוצות במערכות פוליאוריטן המיושמות בנוזל.

מפרט ASTM מרכזי לאיטום פוליאוריטן

תקנים אלה מתארים את המאפיינים ושיטות הבדיקה הנדרשות עבור מוצרי איטום מבוססי פוליאוריטן:

- ASTM C836/C836Mמפרט סטנדרטי עבור ממברנת איטום אלסטומרית בעלת תכולת מוצקים גבוהה, המיושם בנוזל קר, לשימוש עם שכבת שחיקה נפרדת. מפרט זה מכסה תכונות כמו חוזק מתיחה, התארכות, הידבקות וגמישות בטמפרטורה נמוכה עבור ממברנות אלסטומריות, כולל סוגי פוליאוריטן.

- ASTM C957/C957Mמפרט סטנדרטי עבור ממברנת איטום אלסטומרית בעלת תכולת מוצקים גבוהה, המיושם בנוזל קר, עם משטח שחיקה אינטגרלי. דומה ל-C836 אך כולל משטח שחיקה אינטגרלי, החלים על ציפויי פוליאוריטן באזורי תנועת הולכי רגל או כלי רכב.

- ASTM D6947/D6947Mמפרט סטנדרטי לציפוי אוריתן נוזלי מוקצף בלחות המשמש במערכת קירוי פוליאוריטן בהתזה. מתמקד בציפויי פוליאוריטן מוקצפים בלחות לגגות, כולל בדיקות התארכות, חוזק מתיחה וחדירות אדי מים.

- ASTM D8463/D8463Mמפרט סטנדרטי עבור ממברנת איטום אלסטומרית בעלת תכולת מוצקים גבוהה, המיושם בנוזל קר, לשימוש עם שכבת שחיקה נפרדת. תקן עדכני לממברנות פוליאוריטן חד-רכיביות או דו-רכיביות, תוך דגש על ביצועים אלסטומריים ושיטות יישום.

- ASTM D7832/D7832Mמדריך סטנדרטי לתכונות ביצועים של ממברנות איטום המיושמות על קירות מתחת לפני הקרקע. מספק הנחיות לגבי תכונות כמו עמידות למים והידבקות עבור יישומים של פוליאוריטן מתחת לפני הקרקע.

שיטות בדיקה נפוצות של ASTM לאיטום פוליאוריטן

בדיקות אלו מעריכות היבטי ביצועים קריטיים כגון חוזק מכני, עמידות למים והידבקות. רבות מהן מופיעות במפרטים הנ"ל:

| קטגוריית בדיקה | תקן ASTM | תֵאוּר |

|---|---|---|

| ספיגת מים | ASTM D570 | מודד את כמות המים הנספגת על ידי הציפוי, דבר המצביע על יעילות האיטום שלו ועמידותו בפני נפיחות או התפרקות. |

| העברת אדי מים | ASTM E96 | מעריך את קצב מעבר אדי המים דרך הממברנה, דבר קריטי לנשימה ביישומים מסוימים. |

| עמידות ללחץ הידרוסטטי | ASTM D5385 | בודק את יכולתה של הממברנה לעמוד בלחץ מים ללא דליפה, לדמות תנאי מי תהום או הצטברות אגמים. |

| עמידות למים (ערפל/עיבוי) | ASTM D1735 | מעריך את עמידות הציפוי למים במכשיר ערפל, תוך הדמיה של סביבות לחות גבוהה. |

| עמידות למים (עיבוי מבוקר) | ASTM D4585 | קובע את העמידות למים בתנאי לחות מתעבה, ומסייע לחזות ביצועים לטווח ארוך. |

| חוזק מתיחה והתארכות | ASTM D412 | מודד את תכונות המתיחה של הציפוי ואת יכולתו להימתח מבלי להישבר, חיוניים לגמישות ולגישור על סדקים. |

| עמידות בפני קריעה | ASTM D624 | מעריך את חוזק הקרע, המציין עמידות בפני נזק מכני. |

| הידבקות (קילוף) | ASTM D903 | בודק הידבקות קילוף למצעים כמו בטון, ומבטיח שהציפוי נקשר ביעילות. |

| הדבקה (סרט הדבקה/ניתן למשיכה) | ASTM D3359 / ASTM D4541 | מדורג הידבקות באמצעות בדיקת סרט או חוזק משיכה, ומאשר את שלמות הקשר על משטחים שונים. |

| קַשִׁיוּת | ASTM D2240 / ASTM D3363 | מעריך את קשיות החוף או קשיות העיפרון, הקשורה לעמידות בפני שחיקה וקשיחות פני השטח. |

| גישור סדקים | ASTM C1305 | בודק את היכולת לגשר על סדקים במצעים ללא כשל, חיוני למבנים דינמיים. |

| תכולת מוצקים | ASTM D2369 | קובע את אחוז המוצקים הלא נדיפים, ומבטיח ריכוז מוצקים גבוה לכיסוי וביצועים טובים יותר. |

| רכיבה על אופניים קראק | ASTM C836 (חתך בתוך) | מעריך ביצועים תחת פיצוח מחזורי בטמפרטורות נמוכות. |

תקנים ובדיקות אלה מבטיחים שמוצרי איטום מפוליאוריטן מבית Great Ocean עומדים בתקני האיכות והאמינות של התעשייה. לצורך תאימות מוצר ספציפית או בדיקות מותאמות אישית, יש להתייעץ עם הצוות הטכני שלנו או לעיין בפרסומי ASTM העדכניים ביותר, שכן התקנים עשויים להתפתח.

שאלות נפוצות

מהם היתרונות של שימוש בציפויי פוליאוריטן איטום מבית Great Ocean?

הציפויים שלנו מספקים הגנה לאורך זמן עם גמישות גבוהה, פורמולות ידידותיות לסביבה ותאימות למגוון מצעים. הם עמידים בפני מים נצברים, כימיקלים ושחיקה, ומבטיחים שהפרויקטים שלכם יישארו יבשים ובטוחים במשך שנים תוך מזעור צורכי התחזוקה.

כמה עולה ציפוי פוליאוריטן לאיטום?

מחיר ציפוי פוליאוריטן לאיטום משתנה בהתאם לסוג המוצר, לכמות ולצורכי היישום. לקבלת תמחור מדויק, צרו קשר עם צוות המכירות שלנו בכתובת [email protected] או בקשו הצעת מחיר - אנו מציעים מחירים תחרותיים עבור פתרונות איכותיים ומוסמכים המותאמים לפרויקט שלכם.

האם ציפויי פוליאוריטן עמידים למים ידידותיים לסביבה?

כן, אפשרויות הפוליאוריטן המבוססות במים שלנו הן דלות בתרכובות אורגניות נדיפות (VOC) וללא ממס, מה שמפחית את ההשפעה הסביבתית מבלי לפגוע בביצועים. הן מושלמות לפרויקטים של בנייה ירוקה ולאזורים עם הגבלות ריחות מחמירות.

כמה זמן מחזיקים ציפויי פוליאוריטן איטום מעמד?

עם יישום נכון, הציפויים שלנו יכולים להחזיק מעמד 10+ שנים, בהתאם לגורמים סביבתיים. עמידותם לקרינת UV וגמישותם עוזרות להם לעמוד בפני התפשטות, התכווצות ובליה, ומספקות איטום אמין לטווח ארוך.

האם ניתן להשתמש בציפויי פוליאוריטן לאיטום על גגות קיימים?

בהחלט - הם תואמים לרוב חומרי הקירוי הקיימים, אפילו כאלה שנפגעו או פגומים. זה הופך אותם לבחירה מצוינת לתיקונים ושדרוגים ללא צורך בהחלפה מלאה.